Catalyst precursor industrial drying method capable of being easily influenced by temperature and oxygen and system thereof

A drying method and catalyst technology, which are used in drying solid materials, drying gas layout, non-progressive dryers, etc., can solve problems such as drying technology that does not involve industrialization, drying methods that have not been reported, and affect catalyst performance, etc., and achieve savings. Drying time, avoid catalyst wear, effect of low blade speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

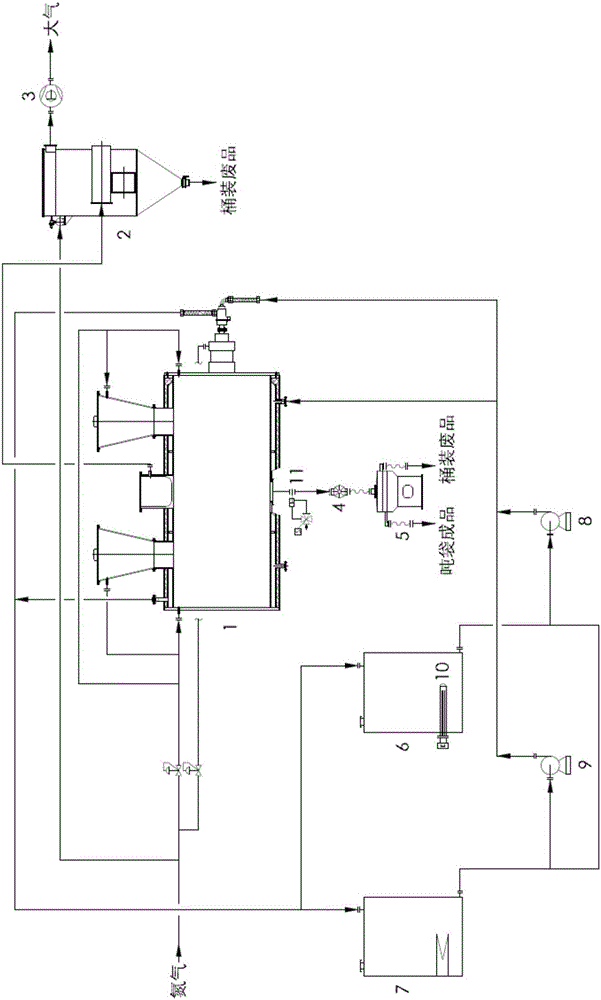

Image

Examples

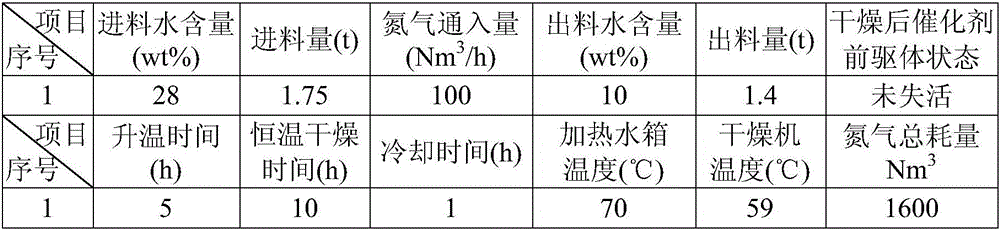

Embodiment 1

[0052] Lift 1.75t of catalyst precursors in barrels with a water content of about 10-30wt% through the lifter to the feeding port of the rake paddle dryer and then add them to the dryer, and use 70°C circulating hot water to dry through the rake paddles The paddle, shaft and jacket of the machine, and the catalyst precursor is continuously stirred by the built-in paddle and rake blades of the rake paddle dryer, and then the catalyst precursor is indirectly dried. The drying time is about 10 hours. During the drying process, the vacuum degree Controlled at -0.05~0MPa(G);

[0053] Among them, the circulating hot water is heated by the electric heater of the heating water tank to reach 70°C, and is pumped to the paddle, shaft and jacket of the rake blade dryer through the heating water; The temperature sensor evenly arranged on the shell of the paddle dryer monitors the evaporation temperature of the material in the dryer, and adjusts the temperature of the medium in the dryer to...

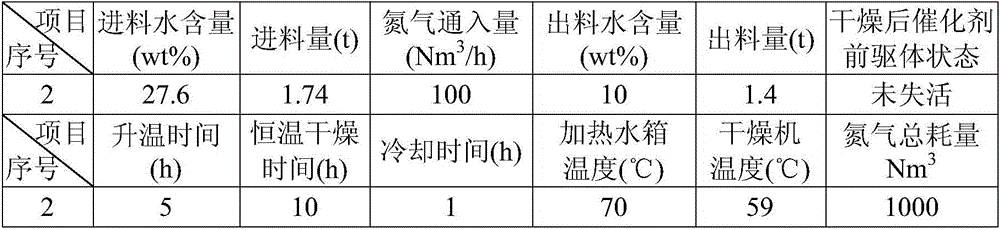

Embodiment 2

[0063] Lift 1.74t of catalyst precursors in barrels with a water content of about 10-30wt% through the lifter to the feeding port of the rake paddle dryer and then add them to the dryer, and use 70°C circulating hot water to dry through the rake paddles The paddle, shaft and jacket of the machine, and the catalyst precursor is continuously stirred by the built-in paddle and rake blades of the rake paddle dryer, and then the catalyst precursor is indirectly dried. The drying time is about 10 hours. During the drying process, the vacuum degree Controlled at -0.05~0MPa(G);

[0064] Among them, the circulating hot water is heated by the electric heater of the heating water tank to reach 70°C, and is pumped to the paddle, shaft and jacket of the rake blade dryer through the heating water; The temperature sensor evenly arranged on the shell of the paddle dryer monitors the evaporation temperature of the material in the dryer, and adjusts the temperature of the medium in the dryer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com