Overlapped liner separating self-blending container

A self-mixing, container technology, applied in the direction of containers, containers with multiple items, closing, etc., can solve the problem of not mentioning more kinds of substances being sealed and stored in the packaging container body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

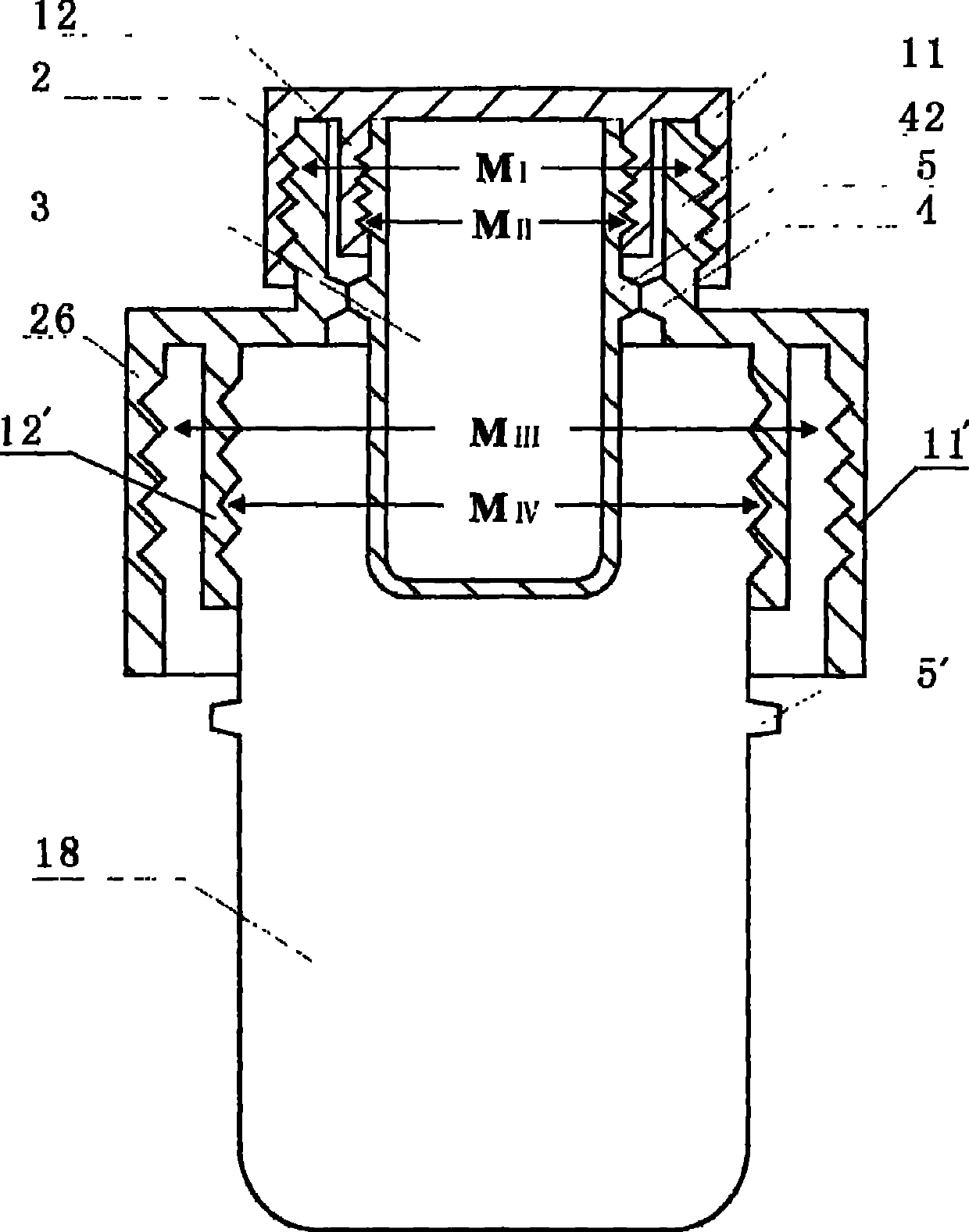

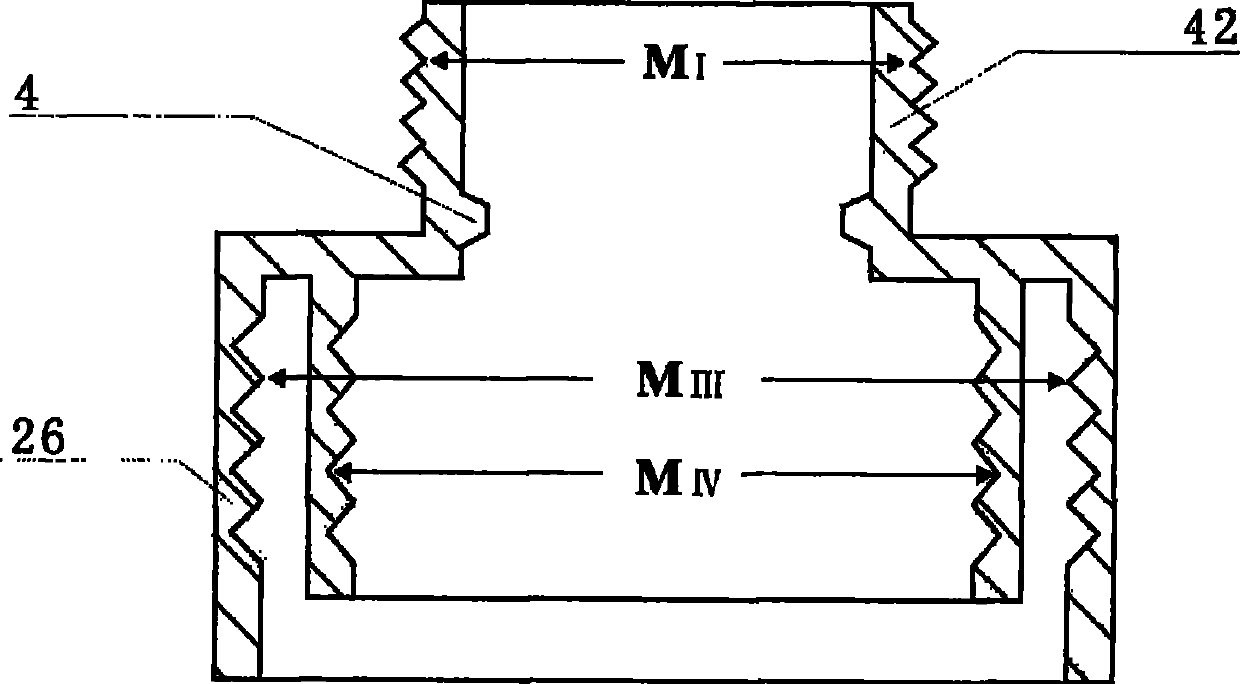

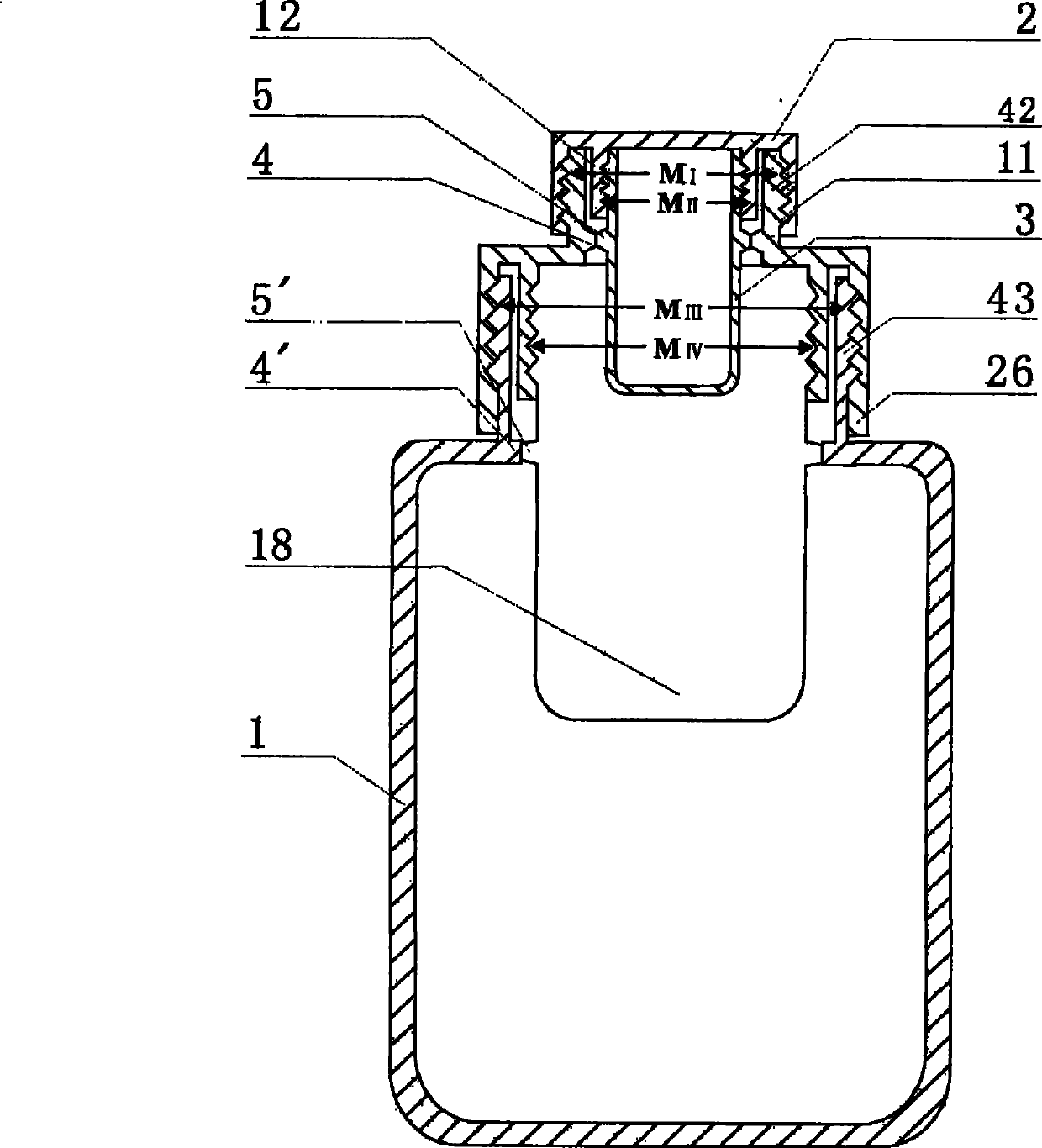

[0048] Example 1: The application of the combination of cap and liner and overlapping combination in the packaging of chlorine dioxide sterilized medicines when connecting the inner and outer liner self-mixing containers

[0049] See Figure 9 , 22 lis of small-sized sprayers are filled with industrial water 23, 3 lis of the upper liner are packaged with activator 24, and 25 are filled with chlorine dioxide stock solution in the lower liner 18.

[0050] When in use, twist the upper cover 2, the upper liner 3 falls off in the lower liner 18, the activator 24 in the upper liner 3 and the chlorine dioxide stock solution 25 in the lower liner 18 realize self-mixing activation, and then twist The lower cover 26 is moved, the upper liner 3 and the lower liner 18 fall off in the small sprayer 22 at the same time, the chlorine dioxide activated in the upper liner 3 and the lower liner 18 is self-mixed and diluted with the industrial water 23 in the small sprayer 22, Produce safe stab...

example 2

[0051] Example 2: The application of the inner-removing self-mixing pesticide spraying machine when the overlapping caps are combined with threaded connection or concave-convex bayonet connection

[0052] Such as Figure 10 As shown, one or more screwed or concave-convex bayonet-connected cover-filler combinations and overlapping combinations can be designed and installed on the top of the pesticide sprayer tool container body 32 . Three different activators 39, 40 and catalysts 41 are placed in the three upper inner tanks 3, pesticide stock solution 37 is placed in another lower inner tank 18 below, and pesticide water 38 is filled in the container body 32 of the pesticide sprayer. When in use, turn the three upper covers 2 sequentially or simultaneously as required, so that the three different activators 39, 40 and catalysts 41 in the three upper inner tanks 3 fall into another lower inner tank 18 below respectively or simultaneously, After activation according to the time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com