A vapor-liquid split micro-negative pressure steam condensate recovery system

A steam condensate and recovery system technology, applied in steam generation, supplementary water supply, preheating, etc., can solve problems such as incomplete recovery of condensate water, poor return of low-pressure condensate water, etc., to achieve online detection and diagnosis, prevent Effect of flash steam discharge and increase of inlet water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

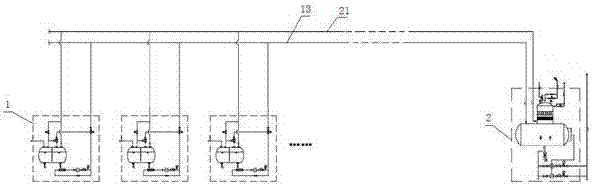

[0030] Such as figure 1 Shown: a vapor-liquid split micro-negative pressure steam condensate recovery system, including a condensate collection device 1 and a condensate recovery device 2 .

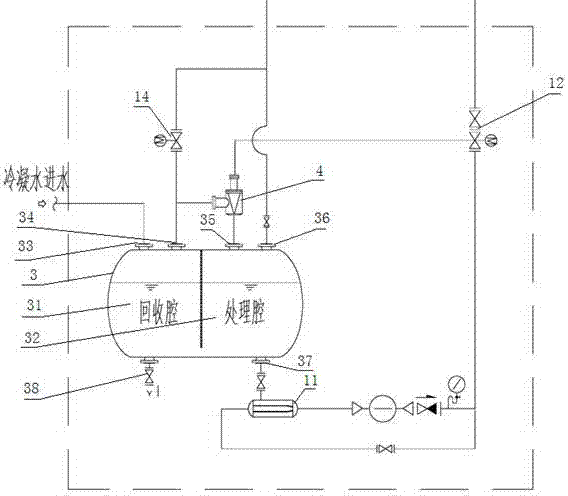

[0031] Such as figure 2 As shown: the condensed water collection device 1 includes a condensed water collection tank 3 and a flash ejector 4, and a first liquid level gauge is provided on one side of the condensed water collection tank 3; the condensed water collection tank 3 includes a recovery chamber 31 and a processing chamber 32, the recovery chamber 31 communicates with the bottom of the treatment chamber 32; the upper part of the recovery chamber 31 is provided with a first condensed water inlet 33 and a first steam exhaust port 34; the upper part of the treatment chamber 32 is provided with a steam-water mixing inlet 35 and a second St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com