Arched ring seal washer and arched ring seal pipe connecting piece

A technology of pipe connection and ring sealing, applied in the direction of pipe/pipe joint/pipe fitting, flange connection, passing element, etc., can solve the problems of high machining accuracy, cannot be reused, not suitable for union, etc., to reduce installation The effect of construction period, steel saving, and convenient installation of pipe connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

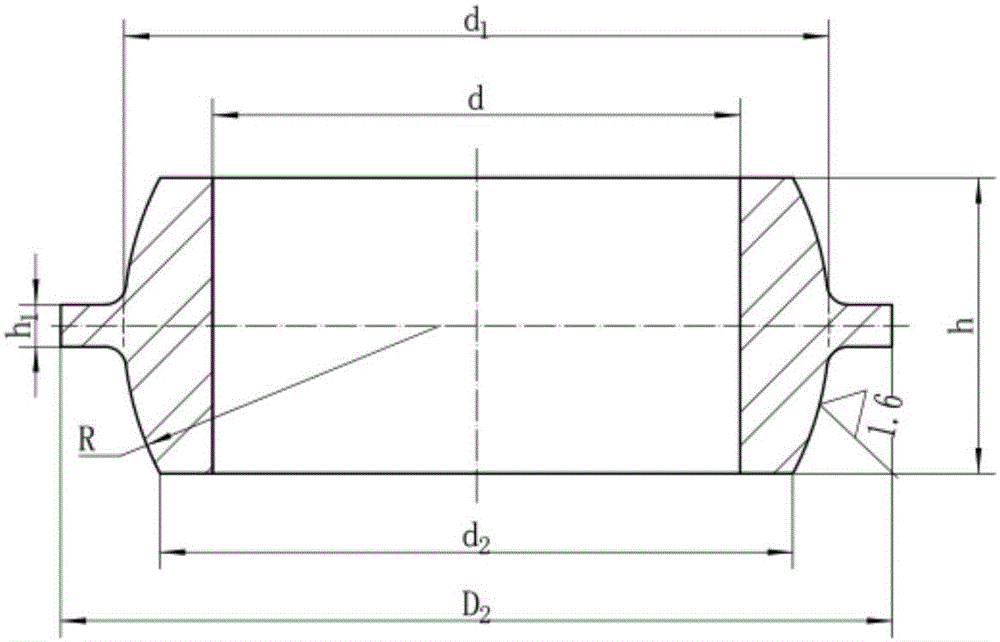

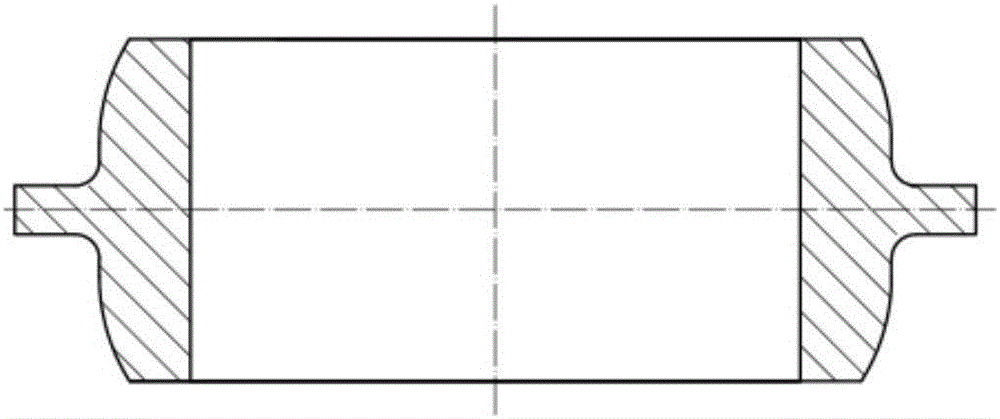

[0058] DN25PN63 union, the gasket is A1 type bow ring, see figure 1 , 10 , R=15mm, α=23°, h=14mm, h1=2mm, and other dimensions are the same as DN25 triangular ring joints, see Chinese Patent Nos. 201320856527.5 and 20152024387.0 for details. The material of bow ring, joint and connection pipe is stainless steel 304, and the material of nut is 20# carbon steel galvanized. 0.5m φ32×3 steel pipes are welded on the connecting pipes and joints. Tighten the gland, pressurize the ferrule valve to 10MPa with a nitrogen cylinder, close the ferrule valve, and remove the connecting pipe between the nitrogen cylinder and the ferrule valve. Immerse the union in water and observe for 10 minutes, there are no air bubbles. After standing for 5 hours, the pressure did not change. Proof.

Embodiment 2

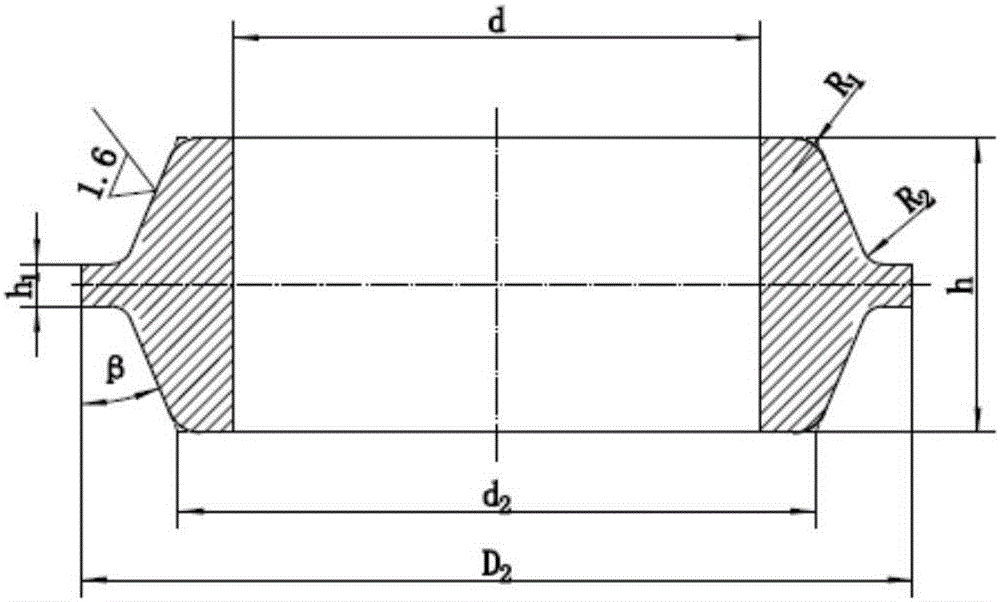

[0060] DN25PN63 joint, the gasket is B1-type bow ring ( image 3 ), α=23°, β=21°, R 1 = 1.6, R 2 = 1, the rest are the same as example 1, see installation Figure 11 . The material of bow ring, joint and connection pipe is stainless steel 304, and the material of nut is 20# carbon steel galvanized. Connect the union as in Example 1, pressurize with a manual pressure test pump, enter water to 20MPa, and close the ferrule valve. After observing for 5 hours, no water seeped out and the pressure did not change.

Embodiment 3

[0062] DN25PN25 union, the gasket is a C-shaped bow ring ( Figure 6 ), α=60°, β=57°, R 1 =0.5, see the connecting pipe, joint sealing surface and installation Figure 13 . The material of joints, pipes and nuts is galvanized 20# carbon steel, and the material of the bow ring is carbon fiber reinforced polytetrafluoroethylene. Connect the union as in Example 1, pressurize with a manual pressure test pump, enter water to 5MPa, and close the ferrule valve. After observing for 5 hours, no water seeped out and the pressure did not change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com