A closed pre-supported tunnel structure

A technology of tunnel structure and pre-support, which is applied in the field of tunnel construction, can solve the problems of easy settlement of tunnels and delays in construction period, and achieve the effects of large promotion value, increased construction speed, and reduced stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

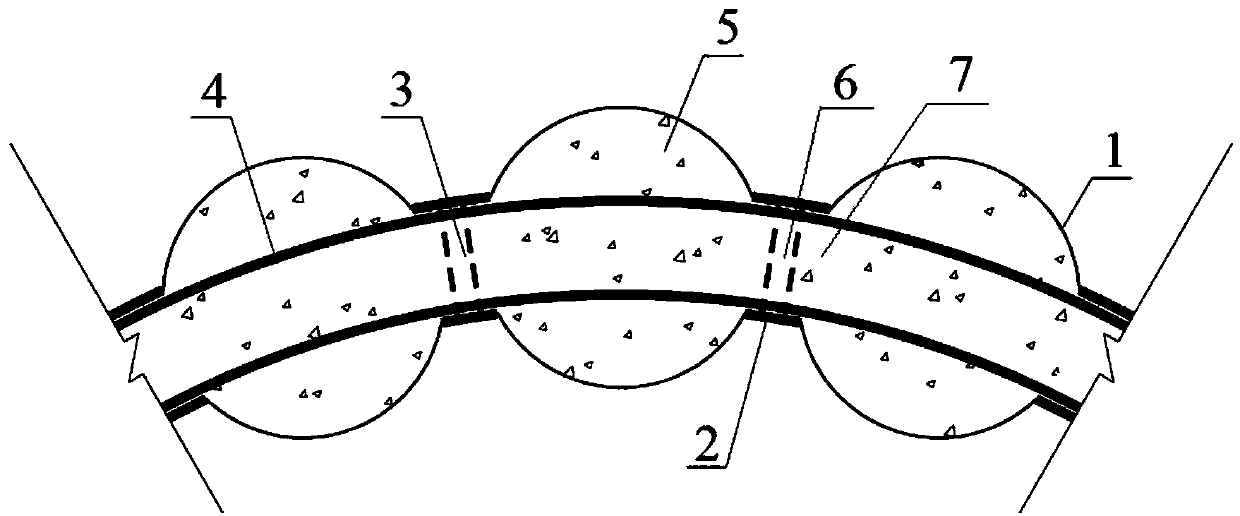

[0035] Such as Figure 1~2 , a closed pre-supported tunnel structure, including figure 1 The a shown in is the ring-shaped pipe curtain structure outside the building boundary of the tunnel. The pipe curtain structure of this embodiment is a ring-shaped arched structure, which has good stability and small settlement, especially at the position below the tunnel boundary. , due to the bottom support of the annular pipe curtain, the pressure above and on both sides of the pipe curtain structure can be transmitted to the bottom of the pipe curtain structure for dissipation, which is equivalent to increasing the stress area and reducing the pressure in the prior art.

[0036] Such as Figure 1~2 As shown, the pipe screen structure of this embodiment includes a plurality of steel pipes 1 arranged along the tunnel axis direction, the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com