Array type ultrasonic vibration oil well paraffin removal & control device

A technology for oil well wax removal and prevention and ultrasonic vibration, which is applied to vibration generating devices, cleaning appliances, wellbore/well components, etc., can solve the problems of complicated oil well wax removal and prevention devices, low efficiency, etc. Easy to use, enhance the effect of ultrasonic vibration intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution and provides detailed implementation methods and specific working processes, but the protection scope of the present invention is not limited to the present invention. Example.

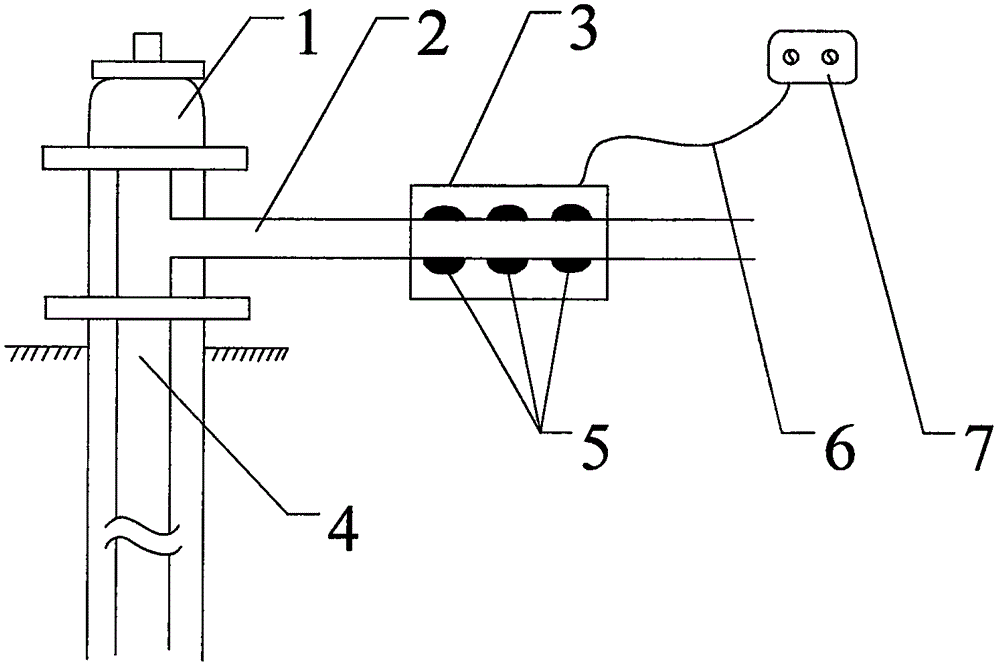

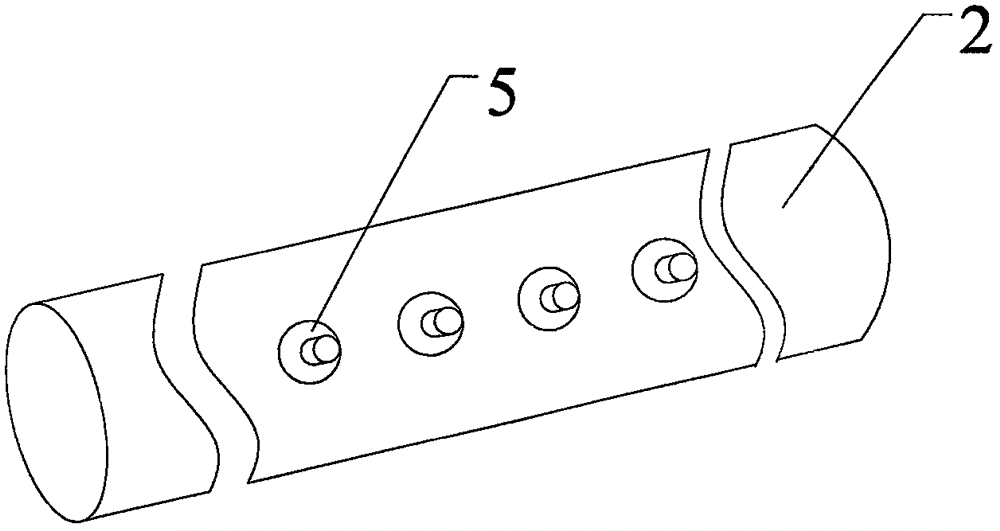

[0023] figure 1 It is a structural schematic diagram of an embodiment of the present invention, figure 2 It is a schematic diagram of the distribution of ultrasonic transducers in Embodiment 1 of the present invention. Such as figure 1 , figure 2 As shown, an array type ultrasonic vibration oil well wax removal and prevention device includes an ultrasonic signal generator 7 , an explosion-proof cable 6 , an ultrasonic transducer 5 and a protective box 3 . The ultrasonic signal transmitter 7 is connected to the ultrasonic transducer 5 through the explosion-proof cable 6, and the ultrasonic transducer 5 is fixedly con...

Embodiment 2

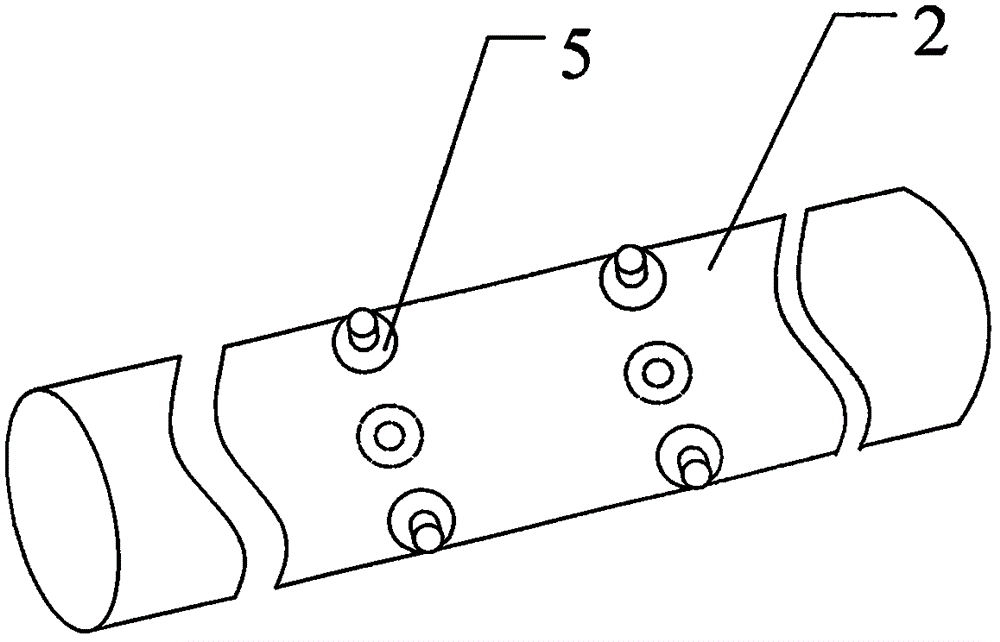

[0028] figure 1 It is a structural schematic diagram of an embodiment of the present invention, image 3 It is a schematic diagram of the distribution of ultrasonic transducers in Embodiment 2 of the present invention, Figure 4 It is a schematic cross-sectional view of the oil outlet pipe in Embodiment 2 of the present invention. Such as figure 1 , image 3 and Figure 4 As shown, an array type ultrasonic vibration oil well wax removal and prevention device includes an ultrasonic signal generator 7 , an explosion-proof cable 6 , an ultrasonic transducer 5 and a protective box 3 . The ultrasonic signal transmitter 7 is connected to the ultrasonic transducer 5 through the explosion-proof cable 6, and the ultrasonic transducer 5 is fixedly connected to the outer wall of the oil well outlet pipe 2.

[0029] In this embodiment, the ultrasonic transducers 5 are arranged in a circular array on the oil outlet pipe 2, and the distances between two adjacent ultrasonic transducers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com