Cement modified soil strengthened geogrid reinforced soil structure and construction method thereof

A technology of geogrid reinforcement and cement modification, which is applied in the construction of cement modified soil reinforced geogrid reinforced soil structure, and in the field of cement modified soil reinforced geogrid reinforced soil structure, which can solve the problem of easy erosion , water damage and other water damage, easy to be scoured and water destroyed, surface soil slide and collapse damage, etc., to improve the ability to resist erosion and water damage, improve the overall shear strength, and strengthen the effect of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

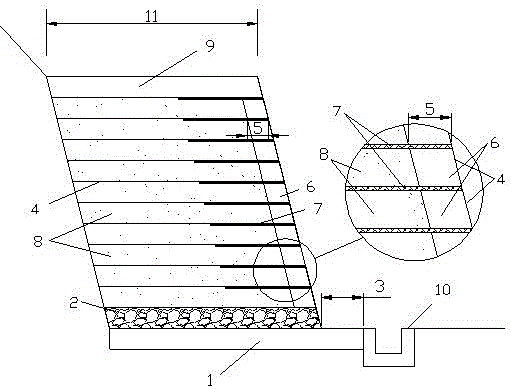

[0008] Attached below figure 1 And the specific construction example of the slope repair application of a gully steep slope in the Deqing granite collapse section of Guangfo-Zhaozhou Expressway, the present invention will be further described.

[0009] see figure 1 , carry out construction according to the following steps:

[0010] 1) Excavate according to the design width of reinforced soil structure 11 and add a width range of 1m outside the slope, and the excavation depth shall not be less than 0.5m;

[0011] 2) Sprinkle the plain soil filler to a soft and plastic state, and evenly sprinkle the cement on the watered soil material according to the weight ratio of cement and wet soil at a ratio of 8%, and use an excavator to carry out road-mixing construction. The cement-modified soil shall be in a hard-plastic state;

[0012] 3) Lay the road-mixed cement-modified soil on the bottom of the excavation area. The virtual pavement thickness is about 70cm. Use an excavator for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com