Device and method for suppressing turbidity of liquid maltitol

A maltitol and liquid technology, applied in the field of functional sugar production, can solve the problems of increased cost, easy turbidity in the storage process of liquid maltitol, short storage period, etc., and achieves the effects of low cost, avoiding turbidity of liquid maltitol, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

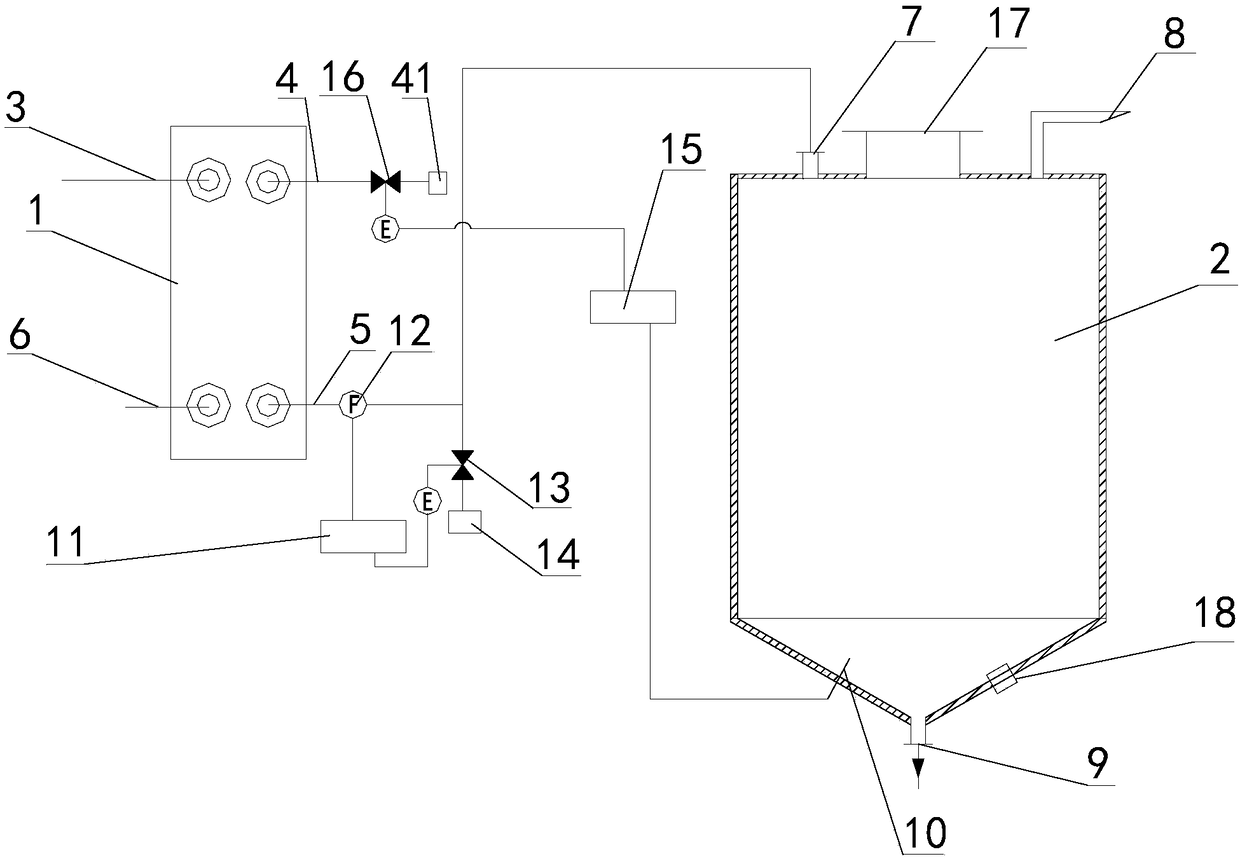

[0048] Such as figure 1 As shown, the heat exchanger 1 adopts a plate heat exchanger.

[0049] (1) Add liquid maltitol with a temperature of 25°C and a light transmittance of 99.0% or more at 420nm detected by a spectrophotometer into the heat exchanger through the feed liquid inlet, while the thermocouple in the storage tank detects the temperature in the storage tank, and The second flow control solenoid valve is controlled by the second PID module to open. At this time, the heat source inlet is passed into the heat exchanger. The heat source is the waste heat of evaporation and concentration, and the temperature of the liquid maltitol is regulated at 50°C through the heat exchanger;

[0050] (2) The liquid maltitol after the temperature control of the heat exchanger in step (1) enters the storage tank through the feed hole, and the electronic flowmeter detects the feed volume of the liquid maltitol, and according to the density of the liquid maltitol, it can be converted O...

Embodiment 2

[0054] Such as figure 1 As shown, the heat exchanger 1 adopts a shell-and-tube heat exchanger.

[0055] (1) Add liquid maltitol with a temperature of 20°C and a light transmittance of 97.0% or more at 420nm detected by a spectrophotometer into the heat exchanger through the feed liquid inlet, while the thermocouple in the storage tank detects the temperature in the storage tank, and The second flow control solenoid valve is controlled by the second PID module to open. At this time, the heat source inlet leads to the heat source into the heat exchanger. The heat source is fresh steam, and the temperature of the liquid maltitol is controlled at 40°C through the heat exchanger;

[0056] (2) The liquid maltitol after the temperature control of the heat exchanger in step (1) enters the storage tank through the feed hole, and the electronic flowmeter detects the feed volume of the liquid maltitol, and according to the density of the liquid maltitol, it can be converted Obtain the q...

Embodiment 3

[0060] Such as figure 1 As shown, the heat exchanger 1 adopts a shell-and-tube heat exchanger.

[0061] (1) Add liquid maltitol with a temperature of 55°C and a light transmittance of 99.5% or more at 420nm detected by a spectrophotometer into the heat exchanger through the feed liquid inlet, while the thermocouple in the storage tank detects the temperature in the storage tank, and The second flow control solenoid valve is controlled by the second PID module to open. At this time, the heat source inlet leads to the heat source into the heat exchanger. The heat source is fresh steam, and the temperature of the liquid maltitol is controlled at 70°C through the heat exchanger;

[0062] (2) The liquid maltitol after the temperature control of the heat exchanger in step (1) enters the storage tank through the feed hole, and the electronic flowmeter detects the feed volume of the liquid maltitol, and according to the density of the liquid maltitol, it can be converted Obtain the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com