Door motor guide rail of elevator

A technology of guide rails and door operators, applied in the field of elevators, can solve problems such as pollution, complicated procedures, and high costs, and achieve the effects of reducing costs, reducing procedures, and facilitating replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

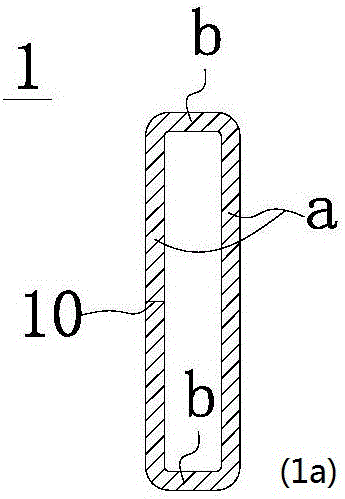

[0038] see Figure 1 to Figure 9 , the door machine guide rail involved in this embodiment is a single door guide rail, the cross section of the closing body 1 is a rectangle with the long side a vertically arranged, and the joint part 10 connecting the end of the closing body 1 is welded by seam welding.

[0039] A short side b or two short sides b extending horizontally of the rectangle adopt rounded corners for transition. The joint part 10 is located on the long side a or the short side b.

[0040] In this example, the joint part 10 is located on the long side a.

[0041] At the same time, according to different requirements, a carrying portion 11 with a protruding surface is provided on the outside of one long side a or two long sides a of the rectangle, and the carrying portion 11 is located in the middle of the long side a.

Embodiment 2

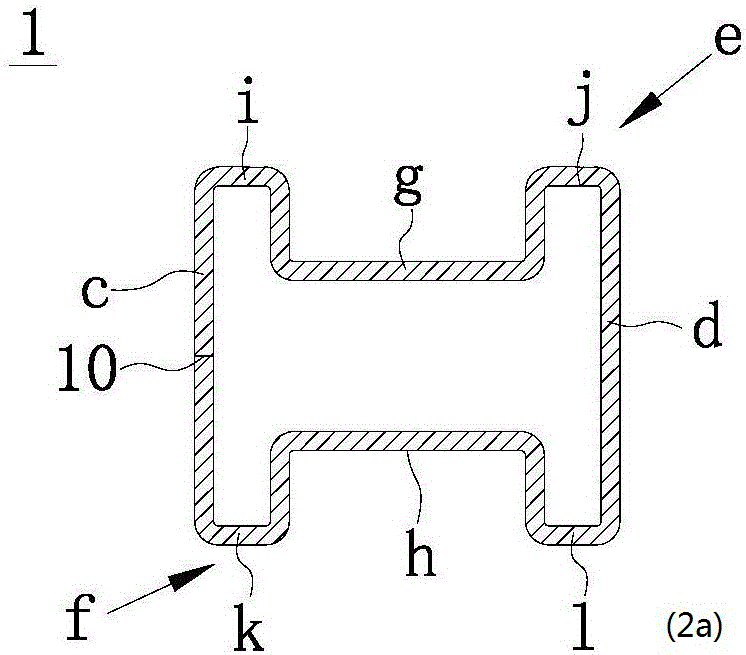

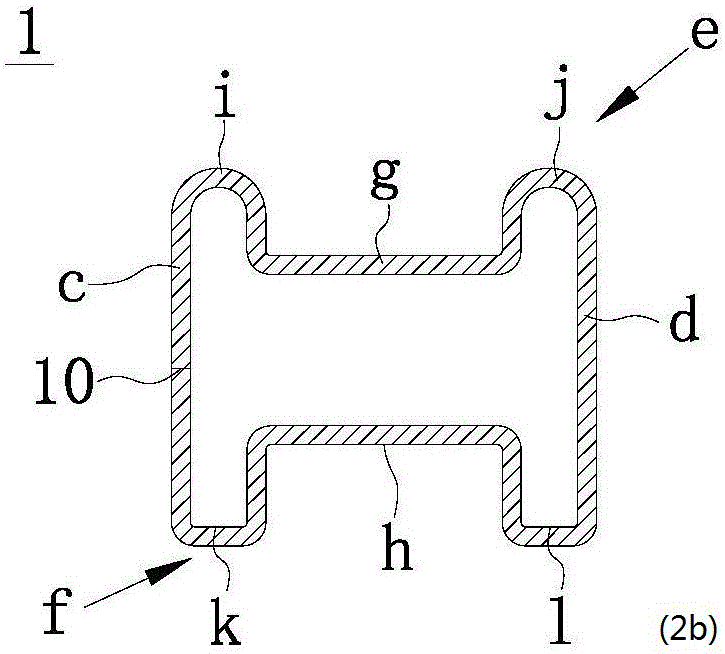

[0043] see Figure 10 to Figure 15 , the door machine guide rail involved in this embodiment is a double door guide rail, the cross section of the closing body 1 is a horizontally arranged I-shape, and the horizontally arranged I-shape includes a first vertical part c and a second vertical part c located on both sides. part d, an upper connecting part e and a lower connecting part f for closed connection of the upper and lower ends of the first vertical part c and the second vertical part d, wherein the upper connecting part e and the lower connecting part f are respectively facing outward The inner recess is set, and an upper recessed area g and a lower recessed area h are formed.

[0044] In this example, the upper connection part e and the lower connection part f are arranged symmetrically.

[0045] The upper recessed area g and the upper parts of the first vertical portion c and the second vertical portion d on both sides form the first protrusion i and the second protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com