Anti-corrosion chassis of air knife slitting machine used for stationery adhesive tape

An adhesive tape and corrosion-resistant technology, which is applied in the field of corrosion-resistant chassis of an air knife slitting machine for stationery adhesive tape, can solve problems such as shortening the service life of the corrosion-resistant chassis, and achieve improved anti-corrosion effects, reduced wear, and good heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

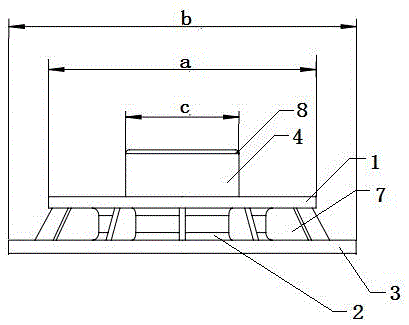

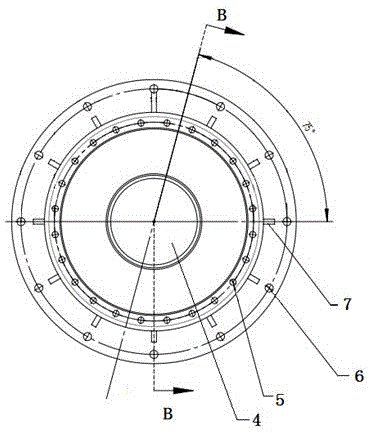

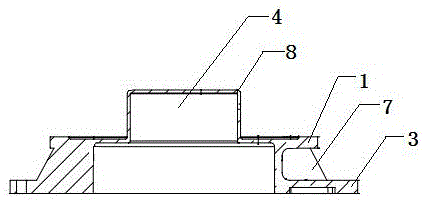

[0018] Such as Figure 1 to Figure 4 The shown corrosion-resistant chassis of an air knife slitting machine for stationery adhesive tape includes a disc-shaped body; the outer surface of the body is sprayed with synthetic plastic; the body is composed of an upper layer 1 and a lower layer 3, and connected The middle layer 2 of the lower layer 1 and 3 is composed of; the diameter a of the upper layer 1 is 708 mm, and the diameter b of the lower layer 3 is 920 mm; the center position of the upper layer 1 is provided with a cylinder 4 with an upwardly protruding diameter c of 300 mm; The upper and lower layers 1, 3 are respectively provided with upper and lower through holes 5, 6; the number of the upper through holes 5 is more than the number of the lower through holes 6, and the size of the upper through holes 5 is smaller than the size of the lower through holes 6; The middle layer 2 is fixed with uniformly distributed serrated teeth 7 ; one end of the teeth 7 is aligned with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com