Improved combined type steel structure shockproof frame

A technology for steel structures and shock mounts, which is applied in earthquake resistance, building components, building structures, etc., can solve the problems of poor earthquake resistance and high cost, and achieve the effects of reducing labor, improving service life, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

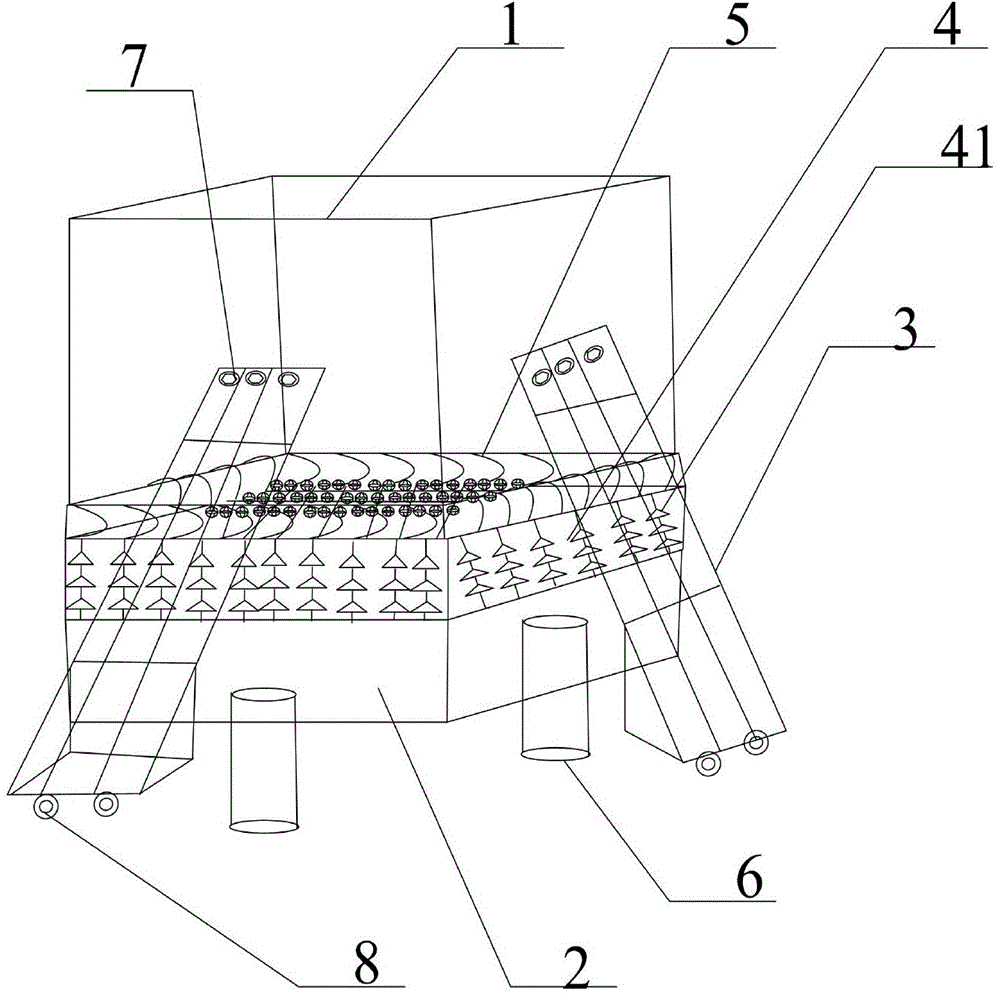

[0019] as attached figure 1 And attached figure 2 Shown:

[0020] The present invention provides a steel structure-based anti-shock device, comprising a base 1, a base 2, reinforcing ribs 3, an anti-shock bracket 4, an isolation layer 5, a steel column 6, bolts 7, and pulleys 8, and the base 1 is set by welding Above the shock-proof layer 5; the shock-proof support 4 is arranged below the shock-proof layer 5 by welding; the base 2 is arranged below the shock-proof support 4; Around; the reinforcing rib 3 is set on the outside of the base body 1 through the bolt 7; the pulley 8 is set under the reinforcing rib 3.

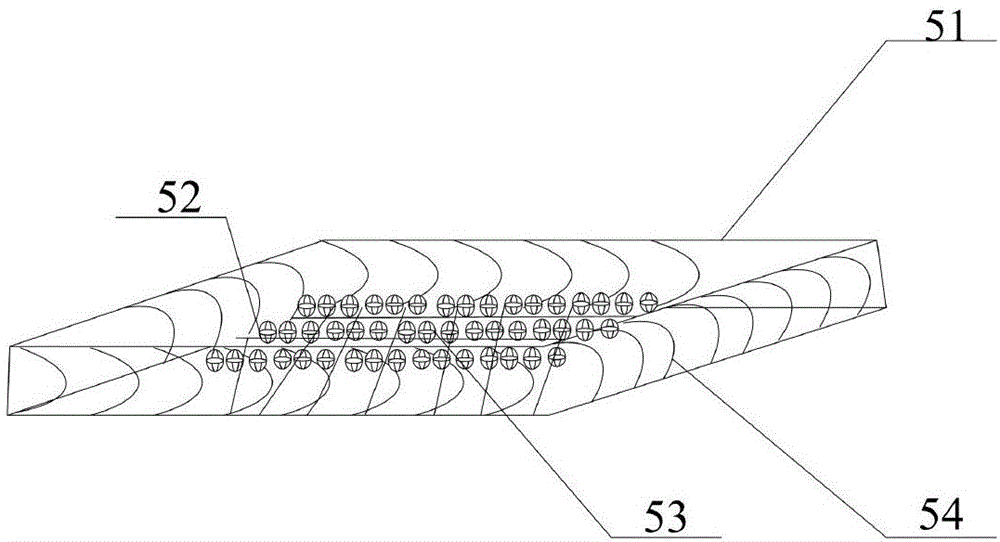

[0021] The shock-isolation layer 5 includes a shock-isolation plate 51, a storage groove 52, a shock-isolation bead 53, and a yieldable rod 54. The shock-proof bead 53 is arranged in the storage groove 52; Above the plate 51; the yieldable rod 54 is arranged around the middle of the shock-absorbing plate 51. When the steel structure receives shock and vibration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com