Automatic paper collection deviation correcting device of box pasting machine

A technology of deviation correction device and folder gluer, which is applied in the direction of transportation and packaging, sending objects, thin material processing, etc., and can solve the problems that affect the quality of glued boxes, improve the yield of glued boxes, waste glued boxes, easy cracking or degumming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

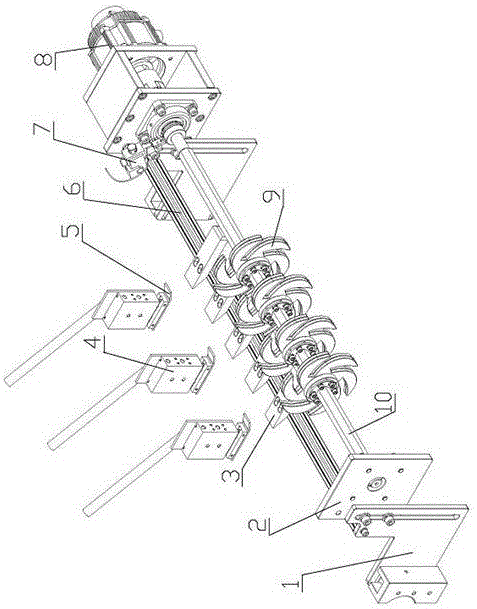

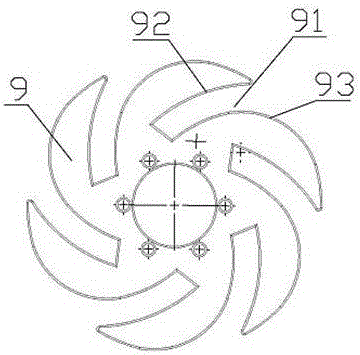

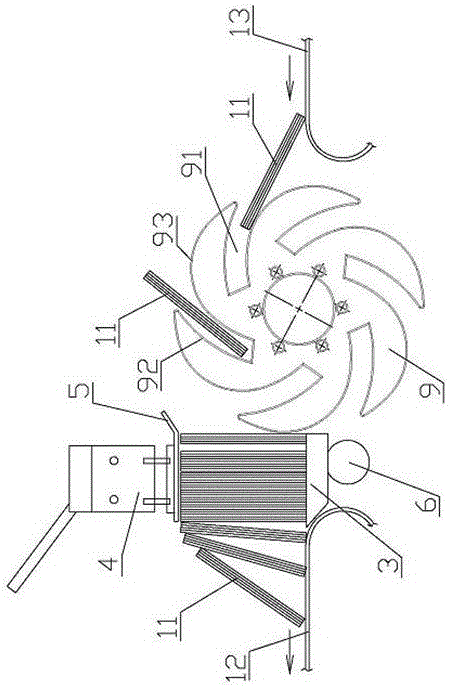

[0022] Such as figure 1 The automatic paper-receiving deviation correction device of the folder-gluer shown in the figure, the deviation correction device includes a frame (not shown in the figure), on which two fixed rod side plates 1 are fixedly installed, and the pallet fixing rod 6 is fixedly connected The fixed rod side plates 1 at its two ends are fixedly installed on the frame. On the supporting plate fixing bar 6, there are several block-shaped deviation correcting and fixed supporting plates 3 fixedly installed, and the number of deviation correcting and fixed supporting plates 3 should be selected and determined according to the carton board structure shape. The upper supporting paper surface of each deviation-correcting fixed pallet 3 can be on the same horizontal plane, or not on a horizontal plane depending on the structure of the carton board; meanwhile, the deviation-correcting fixed pallet 3 can also be a whole plate-like structure. Above the deflection correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com