Steel channel for pipe ditch cover plate, rolling device of steel channel for pipe ditch cover plate and rolling method

A technology of rolling equipment and channel steel, applied in the direction of metal rolling, metal rolling, metal rolling stand, etc., can solve the problems of poor drainage, hidden dangers, easy accumulation of water in the cladding plate, etc., and save production. Cycle time and manufacturing costs, improved stability and rigidity, and the effect of simple manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] On the basis of ensuring the strength of the cladding plate, the hot-rolled channel steel for the pipe trench cover not only has the effects of anti-slip, sound insulation and shock load relief, but also the outer stripes can ensure the timely drainage of rainwater flowing through its surface during the rainy season, thus effectively ensuring safety of the vehicle on which it operates.

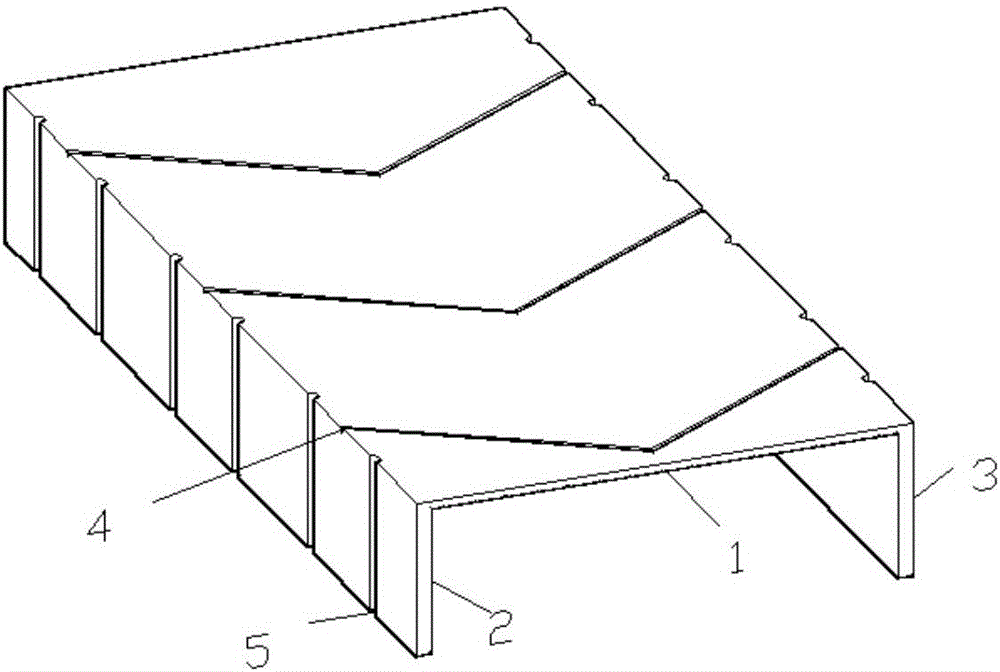

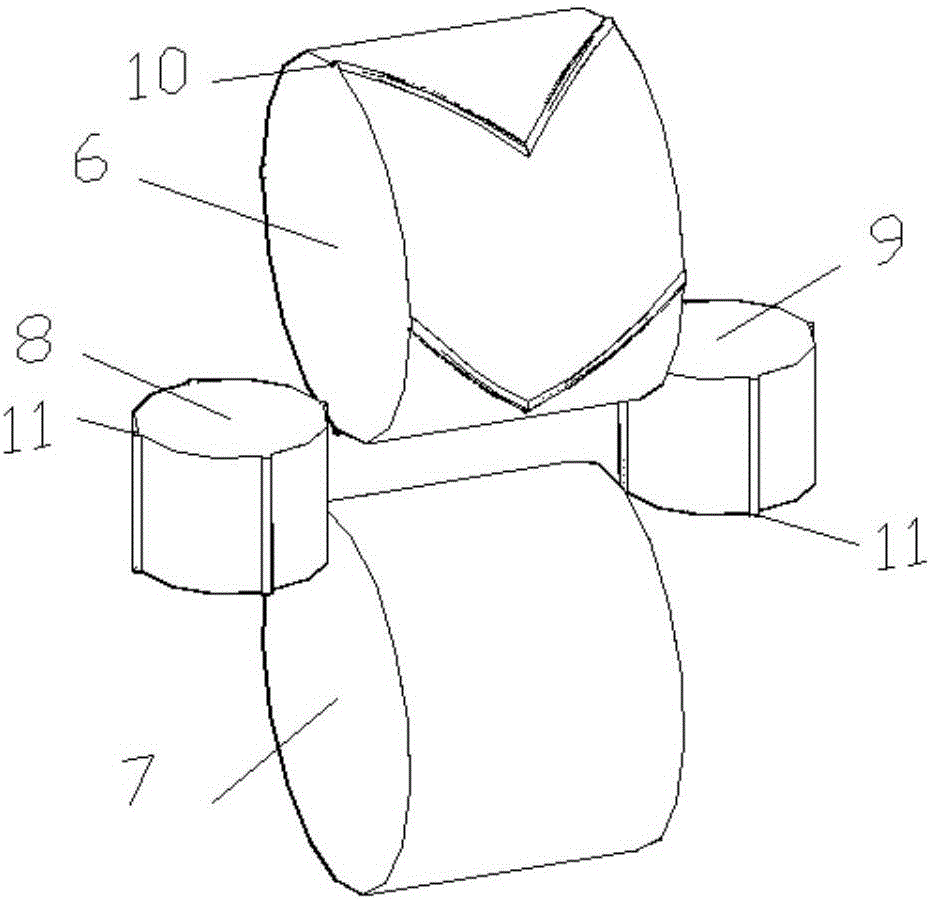

[0031] refer to figure 1 The hot-rolled channel steel for the trench cover includes a hot-rolled channel steel body for the trench cover, 4 concave stripes on the outer side of the web, and 5 concave stripes on the outer side of the flange. The hot-rolled channel steel body for the trench cover has a web 1 1. The first wing plate 2 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com