Preparation method of carbon fiber reinforced ultra-high temperature ceramic matrix composite material

A technology of ultra-high temperature ceramics and composite materials, applied in the field of ceramic matrix composite materials, can solve the problems of insignificant improvement of high-temperature performance of composite materials, low phase volume fraction of ultra-high-temperature ceramics, and obstruction of ultra-high-temperature ceramic particles, so as to avoid performance degradation, The effect of uniform distribution and lower synthesis temperature

Active Publication Date: 2014-01-15

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

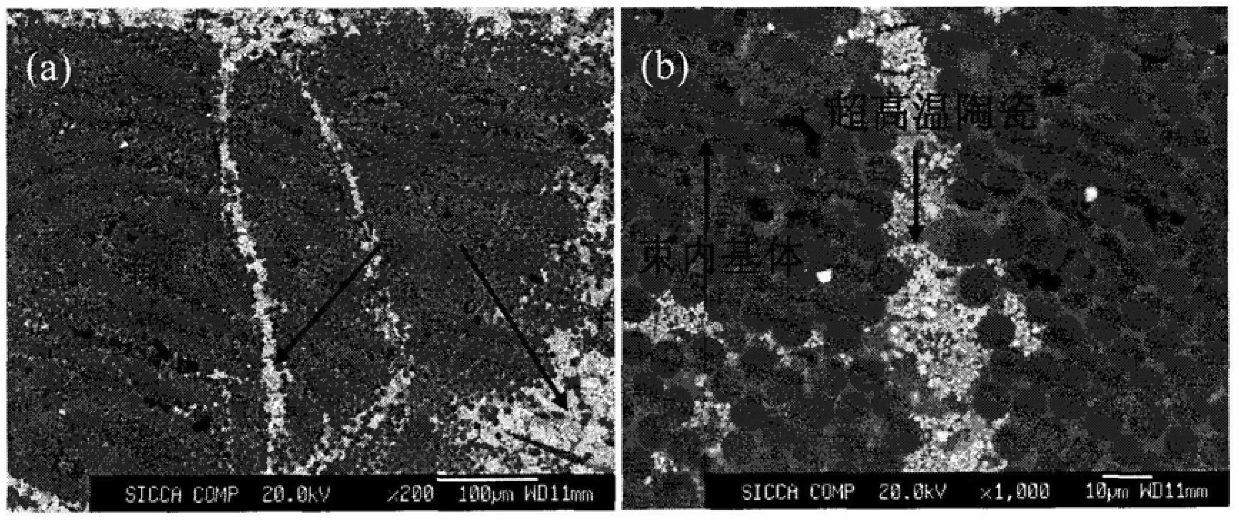

However, due to the impeding effect of the fiber bundles on the ultra-high temperature ceramic particles in the slurry during impregnation, the introduced ultra-high temperature ceramic particles mainly exist in the larger inter-bundle pores, while the pores in the fiber bundles are mainly filled by the precursor cracking products , resulting in a low volume fraction of the introduced ultra-high temperature ceramic phase and uneven distribution in the composite

[Tang, S. F.; Deng, J.Y.; Wang, S.J.; Liu, W.C.; Yang, K., Ablation behaviors of ultra-high temperature ceramic composites, Materials Science and Engineering A 2007, 465, 1-7.; Wang, Z. ; Dong, S.M.; Zhang, X.Y.; Zhou, H.J.; Wu, D.X.; , 3434-3436.; Li Hongbu, Cheng Laifei, Zhang Litong, W.Y., Oxidation analysis of 2D C / ZrC-SiC composites with different coating structures in CH4combustion gas environment Ceramics International 2009, 2009.35(6): 2277-2282; Li, H.B., et al., Fabrication of 2D C / ZrC-SiC composite and its structural evolution under high-temperature treatment up to 1800 degrees C.Ceramics International, 2009.35(7): 2831-2836] When the ultra-high temperature ceramic phase in the composite When the content in the matrix is low and the distribution is uneven, it may lead to insignificant improvement in the high temperature performance of the composite material and inconsistent high temperature performance in different regions of the composite material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

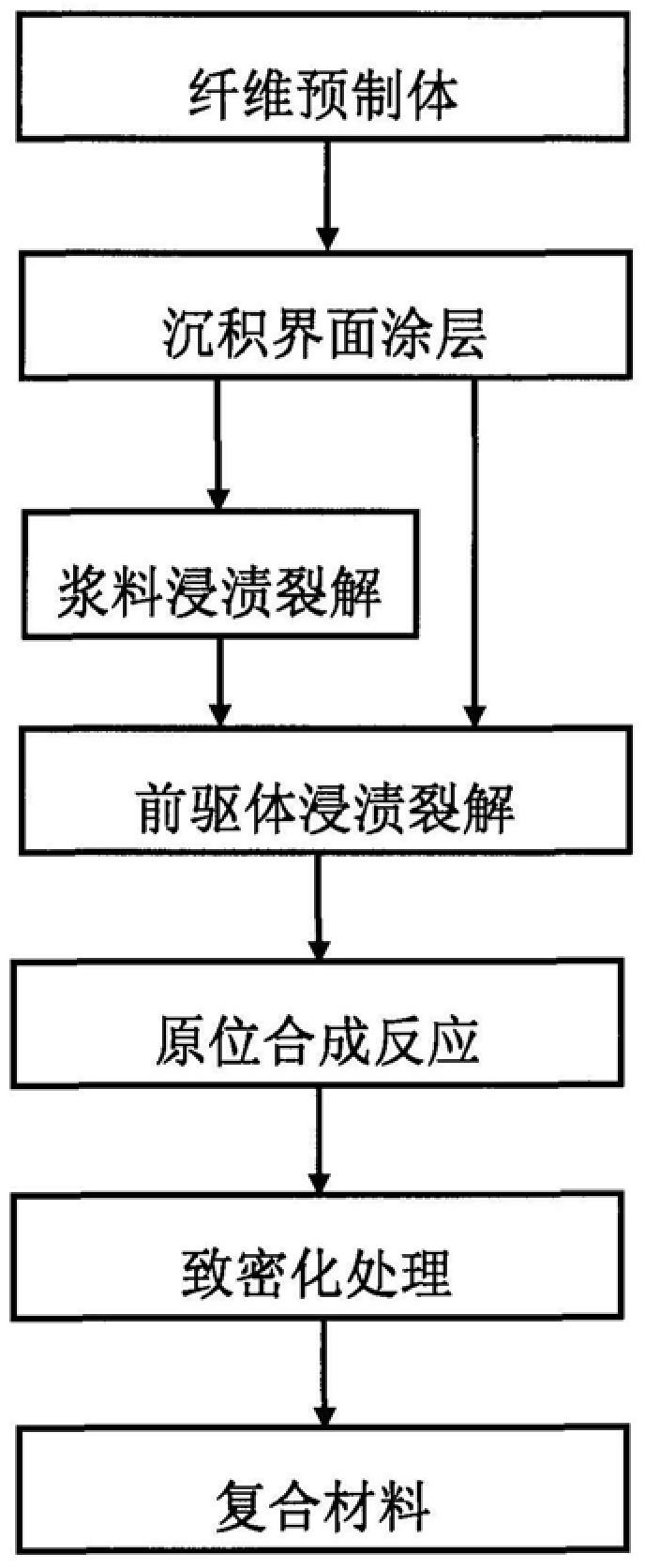

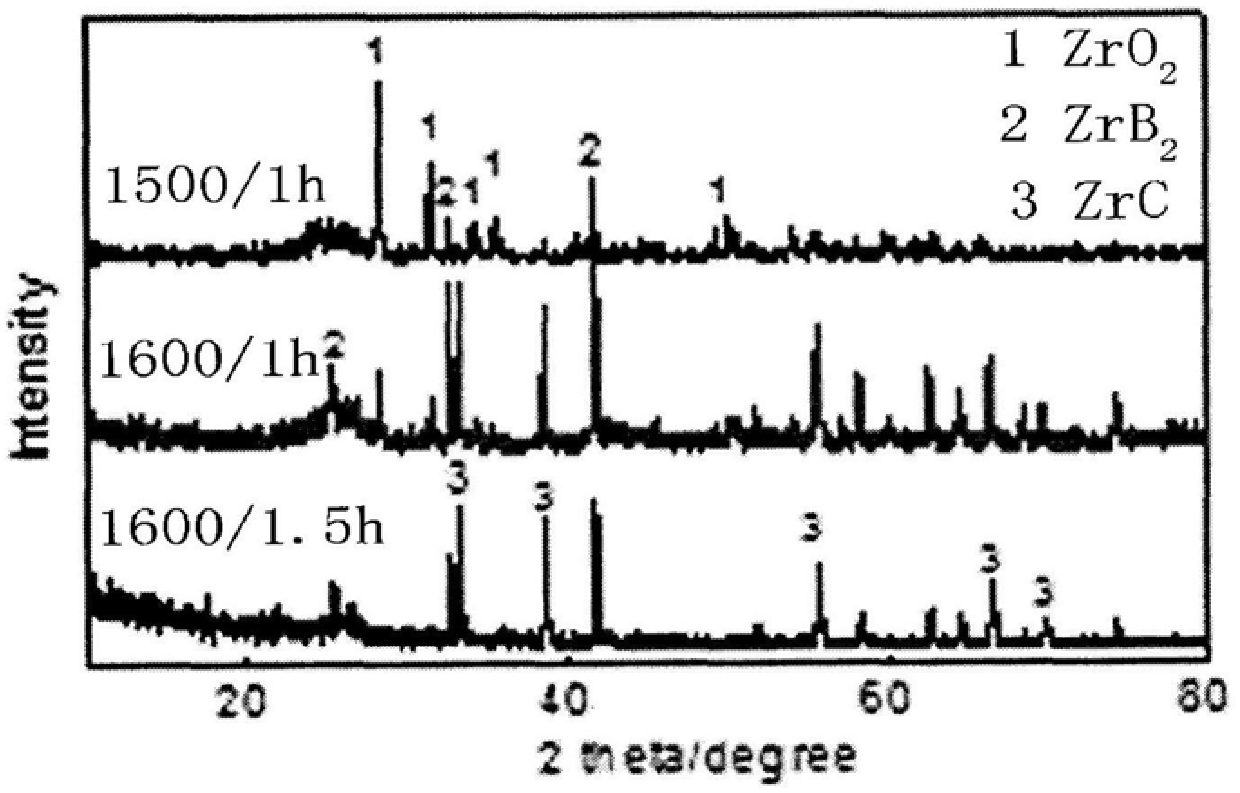

The invention relates to a preparation method of carbon fiber reinforced ultra-high temperature ceramic matrix composite material, belonging to the field of ceramic matrix composite material. The present invention firstly impregnates the soluble precursor containing ultra-high temperature ceramic constituent elements into the composite material, and then synthesizes the ultra-high temperature ceramic phase in situ through the reaction between various substances at high temperature, so as to increase the content of the ultra-high temperature ceramic phase in the matrix of the composite material and the purpose of distribution uniformity. A fiber-reinforced ultra-high temperature ceramic matrix composite material with high content of ultra-high temperature ceramics and uniform distribution is obtained by further densifying the composite material. The method has the advantages of simple process, strong repeatability and simple operation.

Description

Preparation method of carbon fiber reinforced ultra-high temperature ceramic matrix composite material technical field The invention relates to a preparation method of carbon fiber reinforced ultra-high temperature ceramic matrix composite material, belonging to the field of ceramic matrix composite material. Background technique With the development of aerospace technology, the flight speed of aerospace vehicles will be greatly improved. Since the hypersonic vehicle will be subjected to very strong aerodynamic heating during flight, its surface temperature will reach more than 2000°C. Seeking ultra-high temperature resistant materials that can work stably in high temperature environments above 2000 °C has become the research goal of material workers. Although Cf / SiC composites have excellent properties of high temperature resistance, thermal shock resistance, chemical corrosion resistance and high thermal conductivity, when the temperature is higher than 1650 °C, the oxi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C70/40B29C70/06

Inventor 王震董绍明丁玉生何平张翔宇高乐

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com