Microscopic scanning imaging acquisition device for vertical optical element surface damage and method thereof

An optical element, scanning imaging technology, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problem that the position and attitude repeatability of optical elements are not easy to guarantee, affect the reliability of experimental data, and place components. High attitude requirements, etc., to achieve high-precision image stitching and damage detection, to achieve the effect of online rapid damage detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

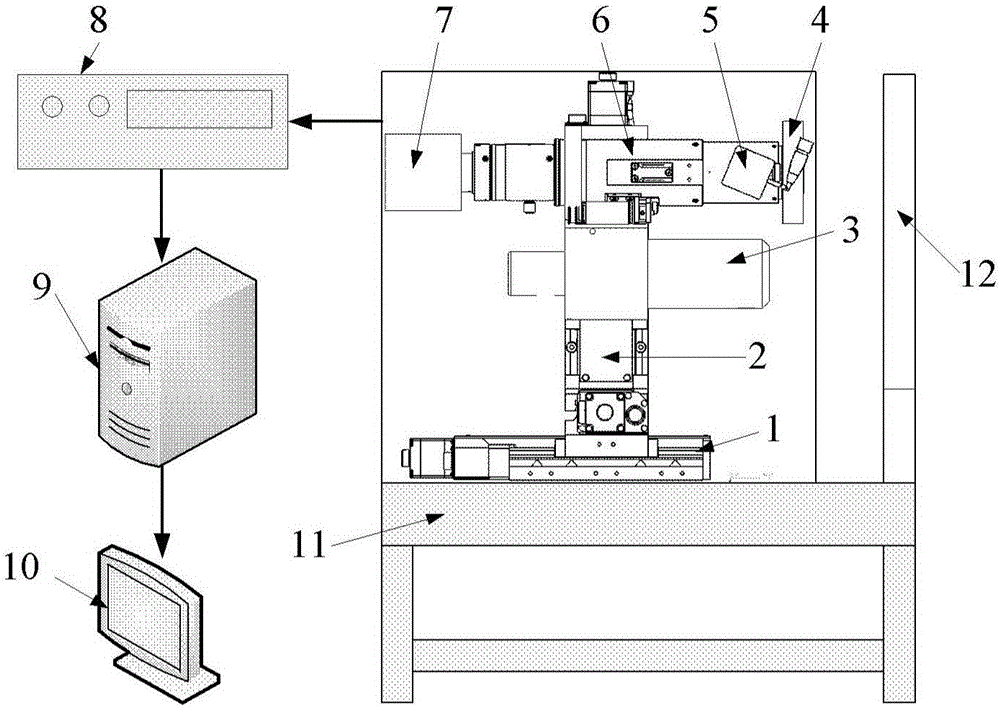

[0022] figure 1 It is a three-dimensional diagram of a microscopic scanning imaging collection device for vertical optical elements disclosed in an embodiment of the present invention, figure 2 It is a flowchart of the work of the vertical optical element microscopic scanning imaging acquisition device in an embodiment of the present invention, such as figure 1 As shown, the device of the present invention includes: a two-dimensional scanning motion platform 2, a one-dimensional focusing axis 1, an automatic zoom microscope lens 6, an area array color CCD 7, a coaxial light source 5, a ring light source 4, and a dispersion confocal displacement sensor 3 , system controller 8, industrial computer 9, shock-isolation platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com