Reluctance Electromagnetic Active Vibration Isolator

An active vibration isolation and reluctance type technology, applied in the direction of shock absorber, magnetic spring, spring/shock absorber, etc., can solve the problems of air gap change, nonlinearity, etc., and achieve small height space, optimized structure, and engineering application strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

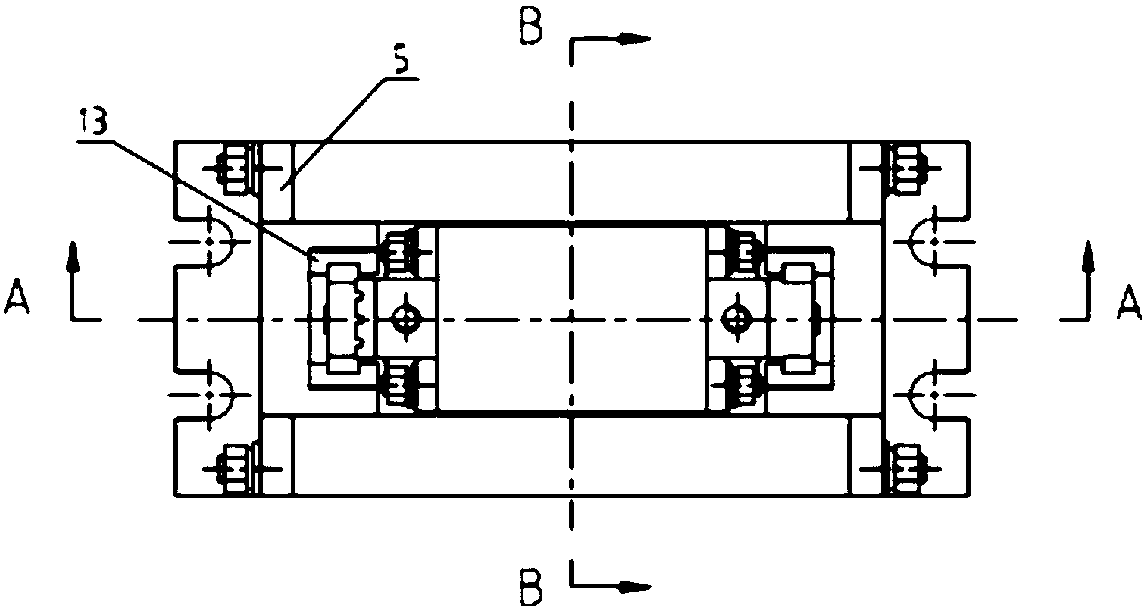

[0016] Referring to the accompanying drawings, a reluctance type electromagnetic active vibration isolator includes: a base plate 1 and a mover assembly and a stator assembly installed on the base plate 1;

[0017] The mover assembly includes: an "I"-shaped mover silicon steel sheet group 6 wound with a coil 14; the upper and lower ends of the mover silicon steel sheet group 6 are respectively equipped with mover silicon steel sheet upper fixing plates 4, The lower fixed plate 7 of the mover silicon steel sheet; the mover guide rail mounting plate 2 is installed between the mover silicon steel sheet upper fixed plate 4 and the mover silicon steel sheet lower fixed plate 7 on each side; each mover guide rail mounting plate 2 There is a pair of rolling guide rails 13;

[0018] The stator assembly includes: two stator yokes 8 with permanent magnets 9 embedded in the center grooves of the end faces; the two sides of each stator yoke 8 are connected with stator silicon steel sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com