Matted gold cardboard and intaglio printing process thereof

A gravure printing process, cardboard technology, applied in printing, wrapping paper, wrapping paper, etc., can solve the problems of easy embossing on the surface, unstable quality, high cost, etc., and achieve the goal of reducing waste treatment, reducing production costs, and saving resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

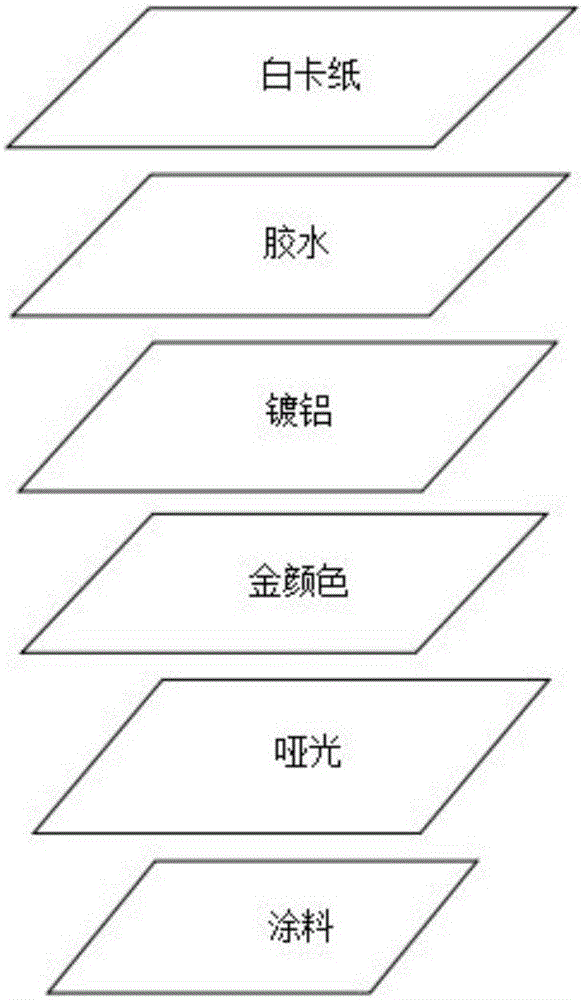

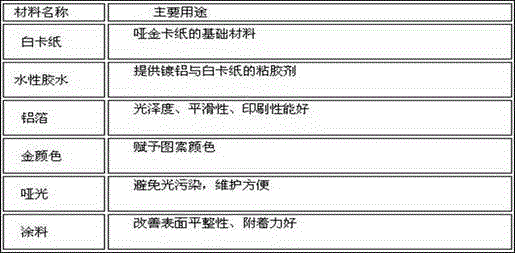

[0019] Such as figure 1 A kind of dumb gold cardboard shown, comprises white cardboard, and one side of described white cardboard is provided with glue layer, aluminized layer, color coating layer, matte layer and paint layer successively; The color is gold, and the CMYK values of the gold are C: 5~7, M: 13~17, Y: 12~16, K: 0~0.5; the tension of the aluminum plating layer is ≥36Dyn, and the thickness is 0.015mm~0.04 mm.

[0020] The technological process of the present invention is: on the composite machine, compound white cardboard and aluminum foil with glue, and then put a layer of adjusted gold color on the aluminum foil, then dry it through the drying tunnel, do matte treatment, and finally apply One coat of primer. The effect obtained is the same as that of matte gold cardboard, and has no effect on subsequent printing.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com