A high-yield process device and method for one-time desalinated water

A technology of process device and process method, which is applied in the direction of general water supply saving, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of increasing water production cost, large investment in equipment, high water production cost, etc., and achieves guaranteed Stability and energy saving, ensuring safe and stable operation, and reducing the risk of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Description:

[0058] The treatment scale of a steel comprehensive wastewater reuse project is 1000m 3 / h, the treatment goal is to prepare wastewater into primary desalinated water for enterprise production, and it is required to maximize the primary desalinated water yield. According to water quality analysis, it is determined that the primary demineralized water yield is 90%, and the primary demineralized water yield is 900m 3 / h.

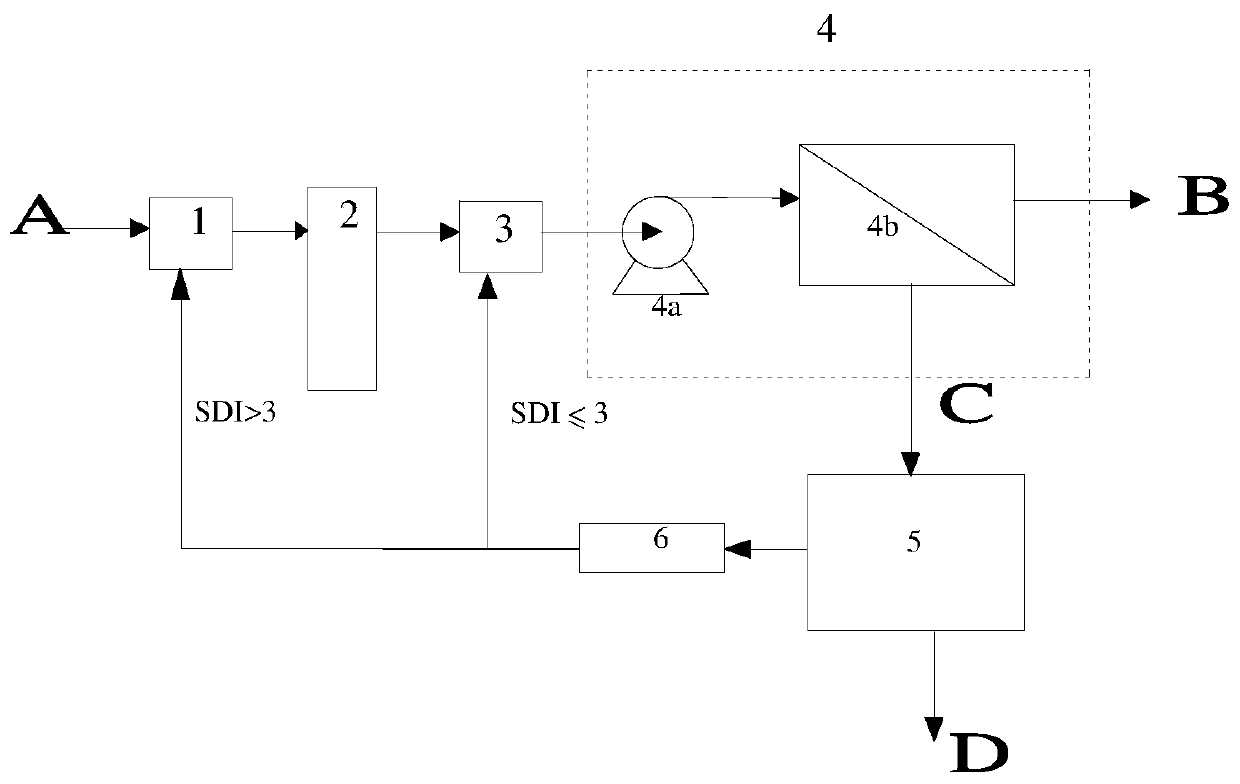

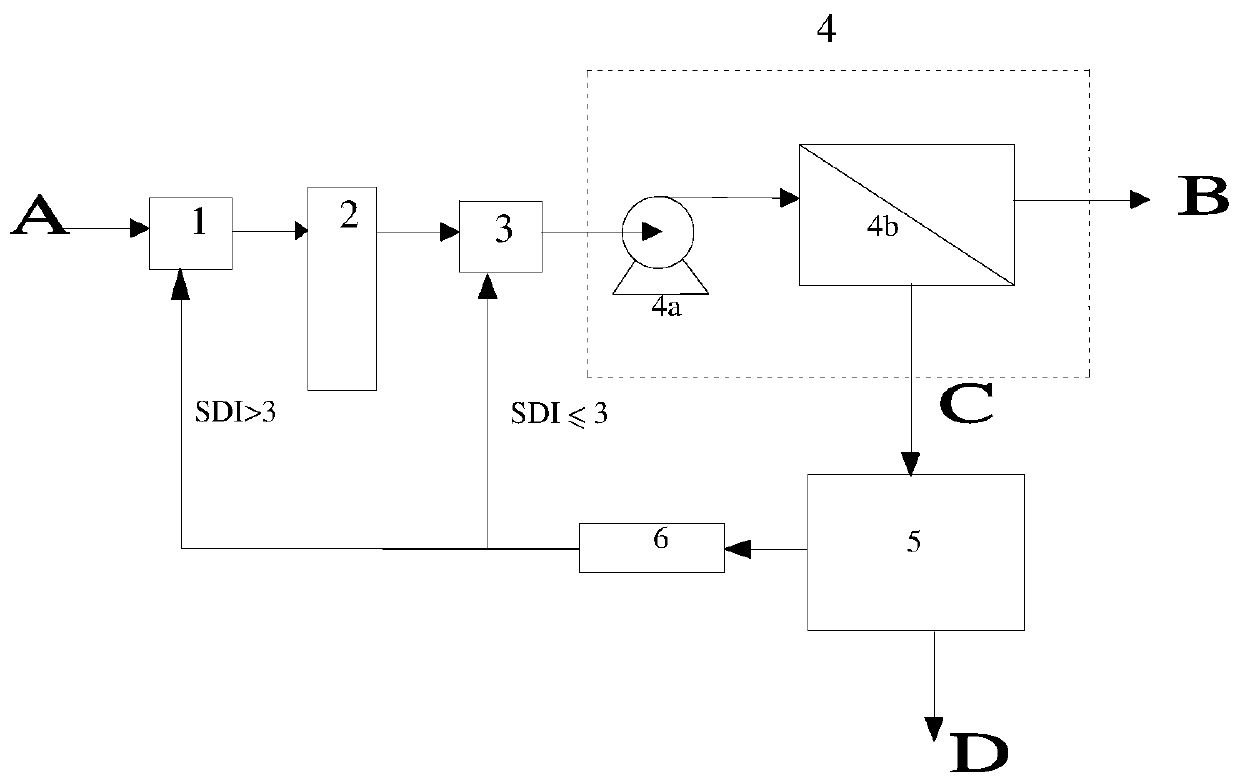

[0059] Combining the actual production, this embodiment provides a high-yield one-time desalination process device, including ultrafiltration pre-water tank 1, pretreatment system 2, intermediate water tank 3, reverse osmosis system 4, electric drive ion membrane equipment 5 and SDI Value online control system 6;

[0060] According to the water quality of the primary desalinated water, the pretreatment system 2 specifically includes a quartz sand filter, an activated carbon filter and a security filter; the quartz sand filter is connected with ...

Embodiment 2

[0086] Description:

[0087] The treatment scale of a steel comprehensive wastewater reuse project is 1000m 3 / h, the treatment goal is to prepare wastewater into primary desalinated water for enterprise production, and it is required to maximize the primary desalinated water yield. According to water quality analysis, it is determined that the primary demineralized water yield is 90%, and the primary demineralized water yield is 900m 3 / h.

[0088] In combination with the actual production, the process device for high-yield primary desalination provided by this embodiment is the same as that of Embodiment 1.

[0089] A high-yield one-time desalination process method adopts the above process device and includes the following steps:

[0090] Step 1. Parameter setting of high-yield one-time demineralization process device

[0091] For the high-yield one-time desalination process device, the specific calculation method of related parameters is:

[0092] (1) The calculation method of the sc...

Embodiment 3

[0112] Description:

[0113] The treatment scale of a steel comprehensive wastewater reuse project is 1000m 3 / h, the treatment goal is to prepare wastewater into primary desalinated water for enterprise production, and it is required to maximize the primary desalinated water yield. According to water quality analysis, it is determined that the primary demineralized water yield is 90%, and the primary demineralized water yield is 900m 3 / h.

[0114] In combination with the actual production, the process device for high-yield primary desalination provided by this embodiment is the same as that of Embodiment 1.

[0115] A high-yield one-time desalination process method adopts the above process device and includes the following steps:

[0116] Step 1. Parameter setting of high-yield one-time demineralization process device

[0117] For the high-yield one-time desalination process device, the specific calculation method of related parameters is:

[0118] (1) The calculation method of the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com