A kind of graphite film composite body and preparation method thereof

A technology of graphite film and composite, which is applied in the field of graphite film polymer composite and its manufacturing, can solve the problems of complex process, low flexural strength of graphite film composite, easy peeling, etc., and achieve simple preparation method, interlayer Strong binding force and good interlayer binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

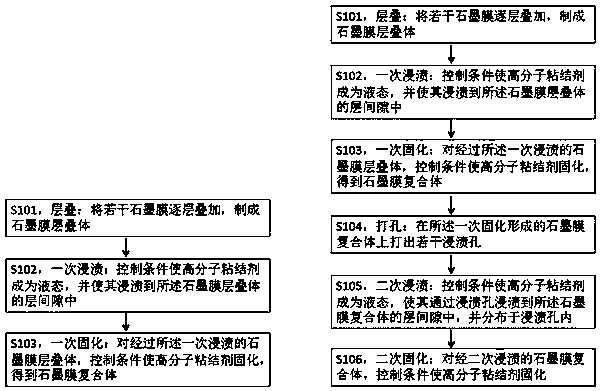

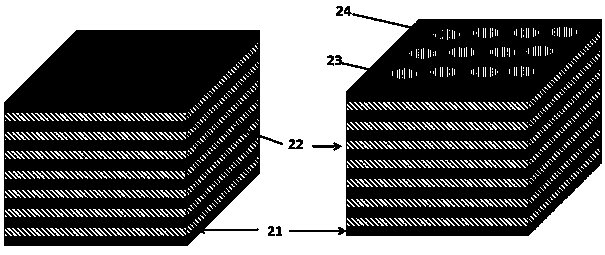

[0048] 1. S101, stacking, stacking 300 commercial expanded graphite films (the first type of graphite film) with a size of 10cm×10cm and a thickness of 50μm layer by layer to form a graphite film laminate.

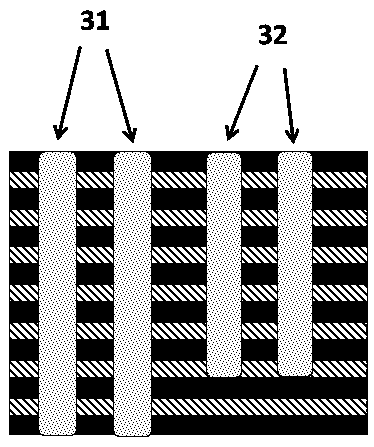

[0049] 2. S102, one impregnation, take 200g of n-butanol and 600g of xylene, mix 800g of diluent according to the ratio of 1:3, then add 800g of diluent to 800g of bisphenol F epoxy resin, stir well, and then add 200g of polyamide resin is used as a curing agent, and stirred evenly to obtain a liquid polymer binder; the graphite film laminate is placed in a mold, and the mold is placed in a vacuum impregnation furnace, and the vacuum impregnation furnace starts to evacuate until the pressure is 10Pa , the temperature in the impregnation furnace is 25°C, open the fluid valve of the vacuum impregnation furnace, flow the liquid polymer binder into the mold, close the fluid valve, immerse for 3 hours, and the pressure is 10Pa, the liquid polymer binder passes through the graphi...

Embodiment 2

[0056] 1. S101, stacking, stacking 200 commercial pyrolytic graphite films (the second type of graphite film) with a size of 5cm×5cm and a thickness of 40μm layer by layer to make a graphite film laminate.

[0057] 2. S102, one impregnation, take 200g of n-butanol and 600g of xylene, mix 800g of diluent according to the ratio of 1:3, then add 800g of diluent to 800g of bisphenol F epoxy resin, stir well, and then add 200g of polyamide resin is used as a curing agent, and stirred evenly to obtain a liquid polymer binder, the graphite film laminate is placed in a mold, the mold is placed in a vacuum impregnation furnace, and the vacuum impregnation furnace starts to evacuate until the pressure is 10Pa , the temperature in the impregnation furnace is 25°C, open the fluid valve of the vacuum impregnation furnace, flow the liquid polymer binder into the mold, close the fluid valve, impregnate for 1.5h, and the pressure is 10Pa, the liquid polymer binder passes through the graphite f...

Embodiment 3

[0064]1. S101, stacking, stacking 100 self-made graphite films with a size of 5cm×5cm and a thickness of 20μm layer by layer to make a graphite film laminate. The graphite film used is the third type of graphite film, which is prepared from graphene oxide. For the specific method, please refer to Ultrathin Flexible Graphene Film: An Excellent Thermal Conducting Material with Efficient EMI Shielding (Advanced Functional Materials, 24(2014), 4542–4548). The specific steps are as follows : 1) Dissolve 5g of graphene oxide in 5000mL of deionized water and stir it ultrasonically for 1 hour; 2) Then pour it into a polytetrafluoroethylene watch glass and dry it at 50°C for 10 hours to remove moisture, and the bottom of the watch glass will be oxidized Graphene film, because the graphene oxide film is poorly bonded to the polytetrafluoroethylene at the bottom, so the graphene oxide film can be peeled off to obtain an independent graphene oxide film; 3) Subsequently, the graphene oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com