Automatic charging system and charging method for overhead transmission line inspection robot

A technology for overhead transmission lines and line inspection robots, which is applied in the direction of signal transmission systems, collectors, circuit devices, etc., can solve the problems that overhead transmission line inspection robots cannot be directly applied, time-consuming and labor-intensive storage batteries, and large energy consumption, etc., to achieve accurate The effect of efficient charging, avoiding power loss, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

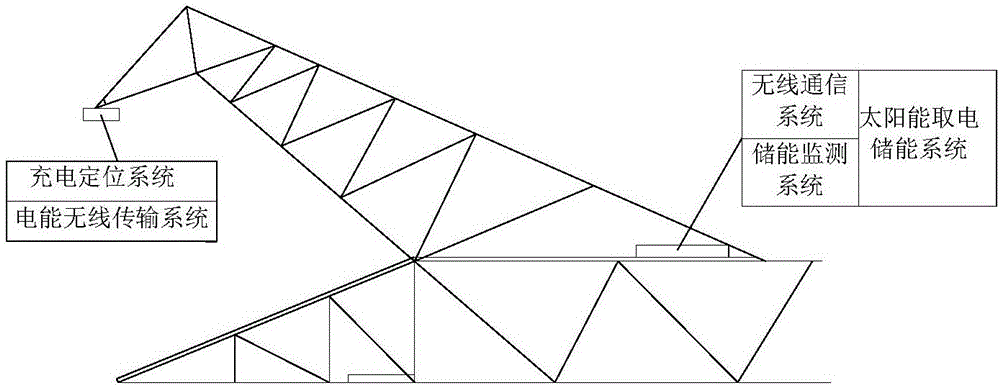

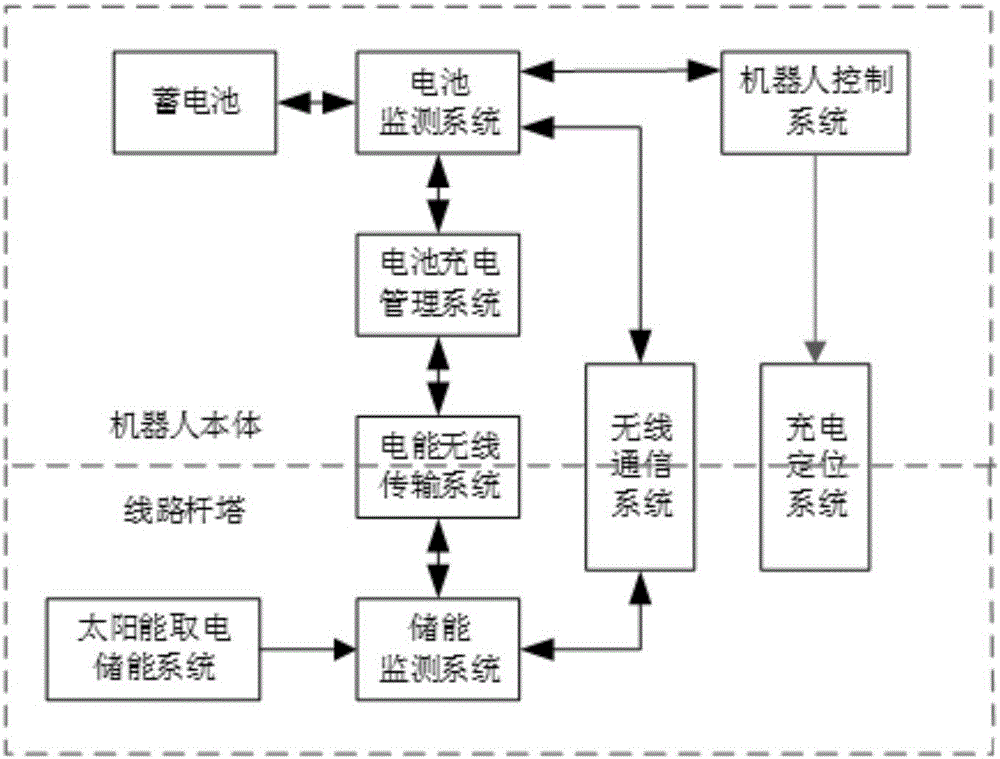

[0035] Such as Figure 1-2 As shown, the autonomous charging system of the overhead transmission line inspection robot of the present invention is mainly composed of a robot storage battery, a battery monitoring system, a battery charging management system, a wireless power transmission system, a charging positioning system, a wireless communication system, a solar energy storage system, a storage Can monitor the system and so on.

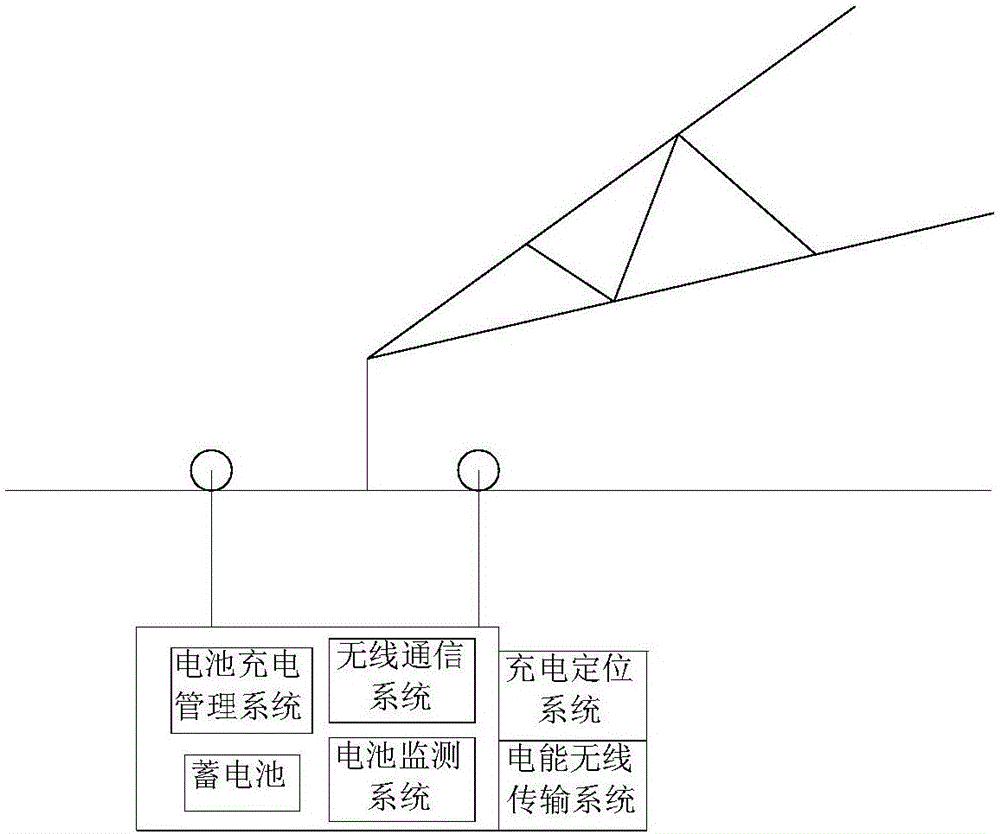

[0036] The installation of each part and the connection structure between them are as follows: image 3 As shown, the storage battery, battery detection system, and battery charging management system are installed on the patrol robot body; the solar energy storage system and energy storage monitoring system are installed on the overhead line tower; the electric energy wireless transmission system, charging positioning system, wireless communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com