Automatic mode-locked fiber laser and application thereof

A fiber laser and automatic mode-locking technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of expensive, unsatisfactory simplicity, cheapness, miniaturization, etc., and achieve easy implementation, simple and efficient implementation, and improved work efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

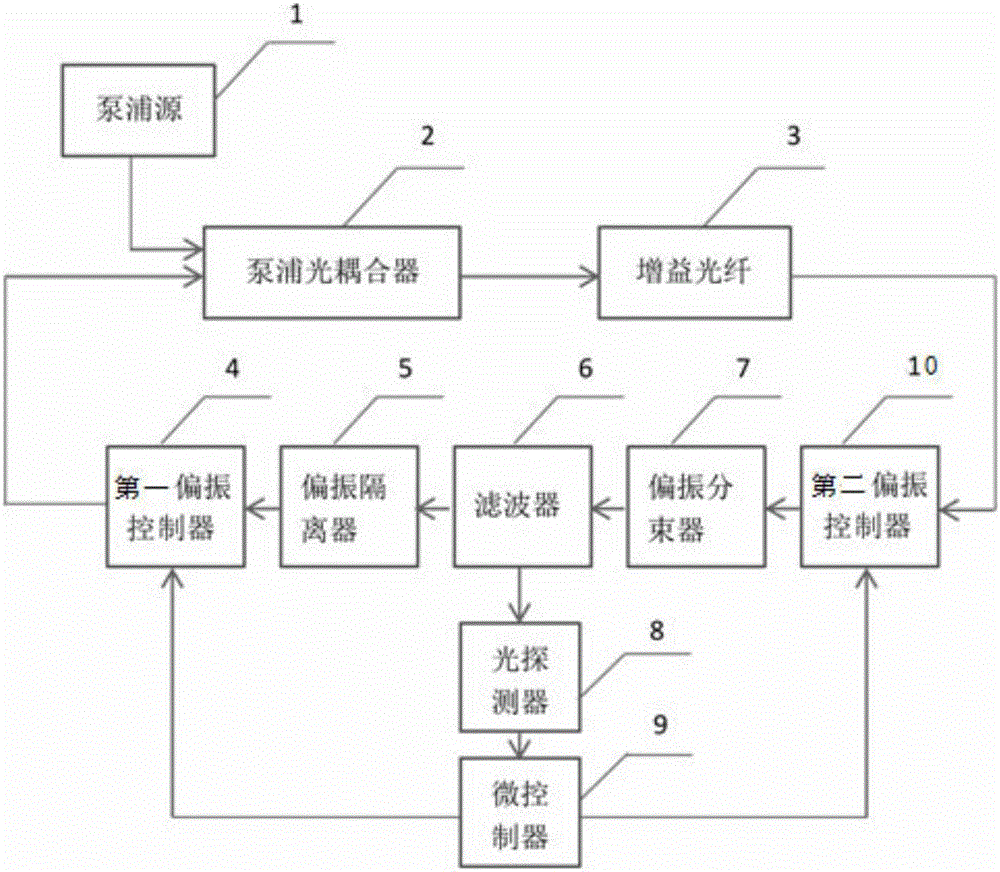

[0037] like figure 1 shown.

[0038] An automatic mode-locked fiber laser, including a fiber laser and an automatic mode-locked control module; the fiber laser includes a pumping source 1 and a resonant cavity; the resonant cavity includes a pumping optical coupler 2, a gain An optical fiber 3, a first polarization controller 4, a polarization beam splitter 7, a filter 6, a polarization isolator 5 and a second polarization controller 10; the automatic mode-locking control module includes an optical detector 8 and a microcontroller 9; The filter 6 is connected to a microcontroller 9 through a photodetector 8 . The photodetector 8 is used to detect the laser output from the filter 6, and the microcontroller 9 counts and detects the signal level of the photodetector 8 so as to judge the current working state of the laser, and simultaneously according to the current state of the fiber laser The state automatically adjusts the polarization controller to obtain the function of aut...

Embodiment 2

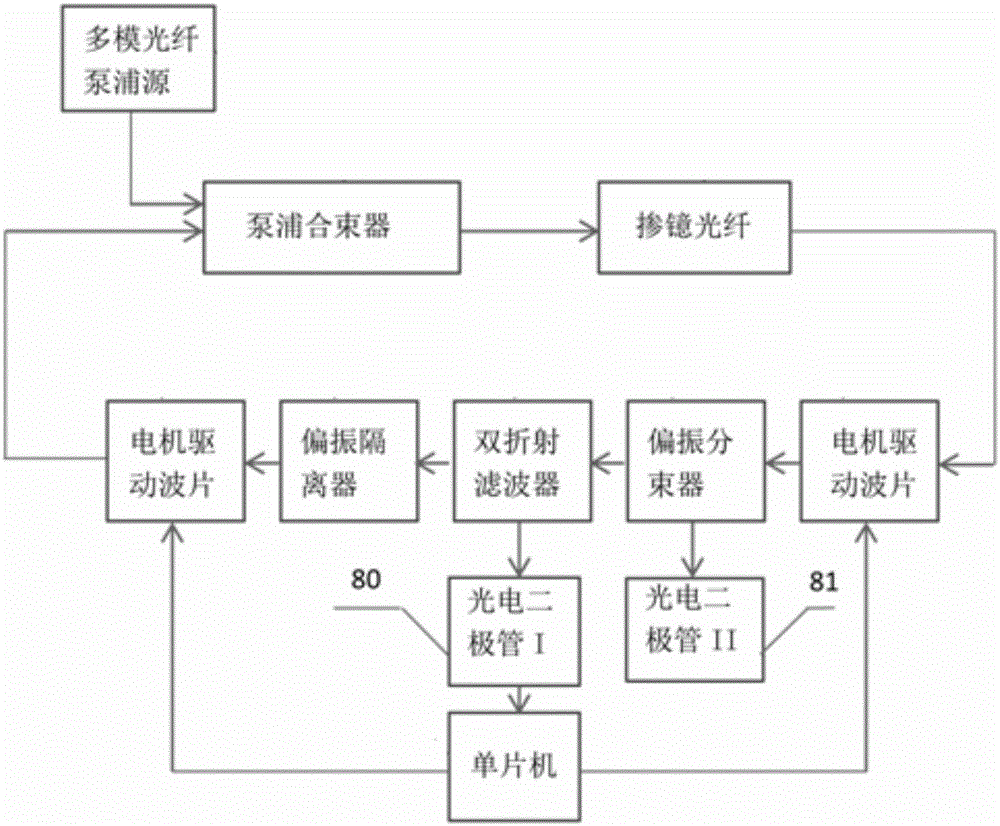

[0040] As in the automatic mode-locked fiber laser described in Embodiment 1, the difference is that the pumping source 1 is a multimode fiber semiconductor laser.

Embodiment 3

[0042] As in the automatic mode-locked fiber laser described in Embodiment 1, the difference is that the pump optical coupler 2 is a pump beam combiner with a fiber structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com