Soft magnetic manganese-zinc ferrite material with ultrahigh magnetic permeability and preparation method thereof

A technology of manganese-zinc ferrite and magnetic permeability, which is applied in the direction of magnetism of inorganic materials, can solve the problem of difficult to have ultra-high permeability ferrite materials, and can reduce the magnetic crystal anisotropy constant and increase the density. , the effect of ultra-high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing an ultrahigh magnetic permeability soft magnetic manganese zinc ferrite material, the specific steps are as follows:

[0030] (1) Mixing: According to the components and mole percentages of the main ingredient formula in the raw materials, weigh 51-55% of iron oxide, 15-20% of zinc oxide, the remainder of manganese oxide and trace element CaCO 3 (Primary mixing plus CaCO 3 , secondary sanding without adding CaCO 3 process), red sand and black sand were mixed for 40 minutes to 1 hour to obtain a powder with uniform main ingredients and high sintering activity; the particle size of the mixed powder was controlled at about 1.0-1.4 μm.

[0031] (2) Pre-burning: Put the above mixed powder into the rotary kiln for pre-burning, the pre-fired temperature is 800-950°C, the pre-fired time is 40-70 minutes, the flow rate of the mixed powder is controlled at about 6kg / min, and the rotary kiln speed is 5-20 rev / min, make the red mixed powder react initially ...

Embodiment 2~12

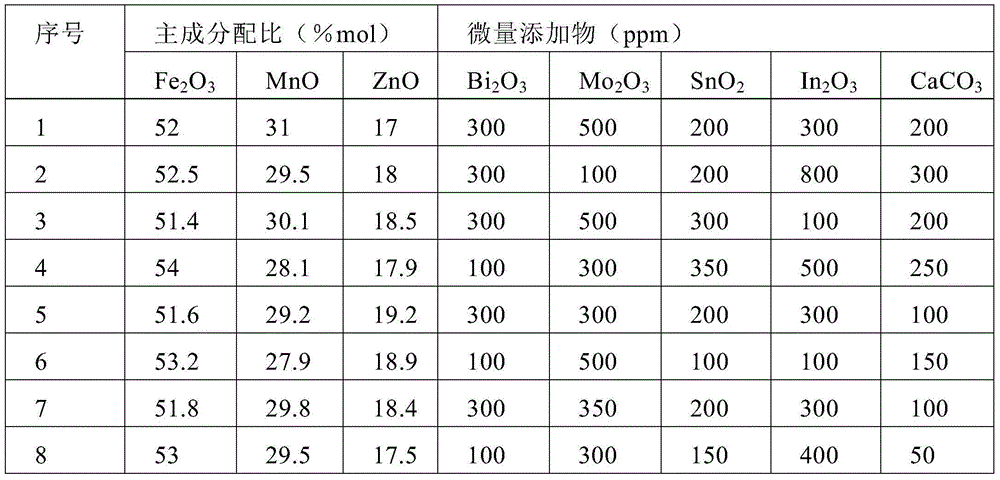

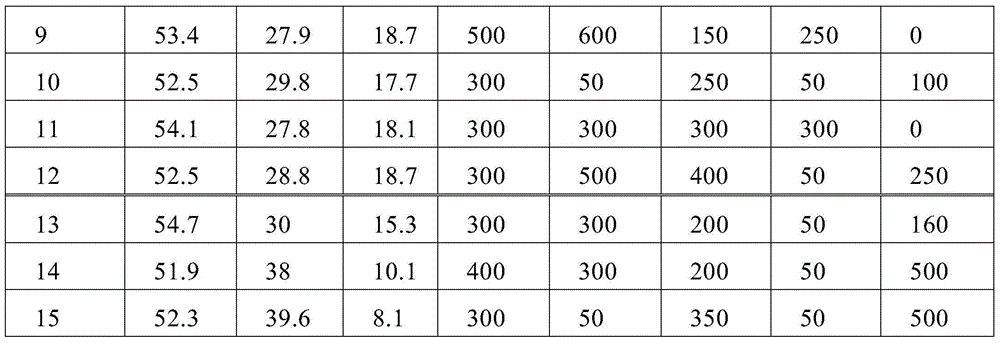

[0039] Using the steps and preparation method of Example 1, different proportions of main components and addition amounts of trace additives (as shown in Table 1) were selected to prepare samples respectively.

Embodiment 16

[0050] A method for preparing a wide-temperature soft magnetic manganese-zinc ferrite material with high magnetic permeability and good low-temperature characteristics, the specific steps are as follows:

[0051] (1) Mixing: According to the components and mole percentages of the main ingredient formula in the raw materials, weigh 55% of iron oxide, 15% of zinc oxide, and the remainder of manganese oxide, and use a strong mixer to mix for 2 hours to obtain a powder containing the main ingredient ;The particle size of the mixed powder is controlled at about 1.0-1.5 μm, the purpose is to make the raw materials mix evenly, so as to facilitate the complete preliminary solid-phase reaction during pre-calcination;

[0052] (2) Pre-burning: Put the powder of the above mixed main components into the rotary kiln for pre-burning, the pre-burning temperature is 900°C, the pre-burning time is 70 minutes, the flow rate of the mixed powder is controlled at about 4 kg / min, and the rotary kiln...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com