A two-stage temperature control device for a pump-driven two-phase fluid circuit

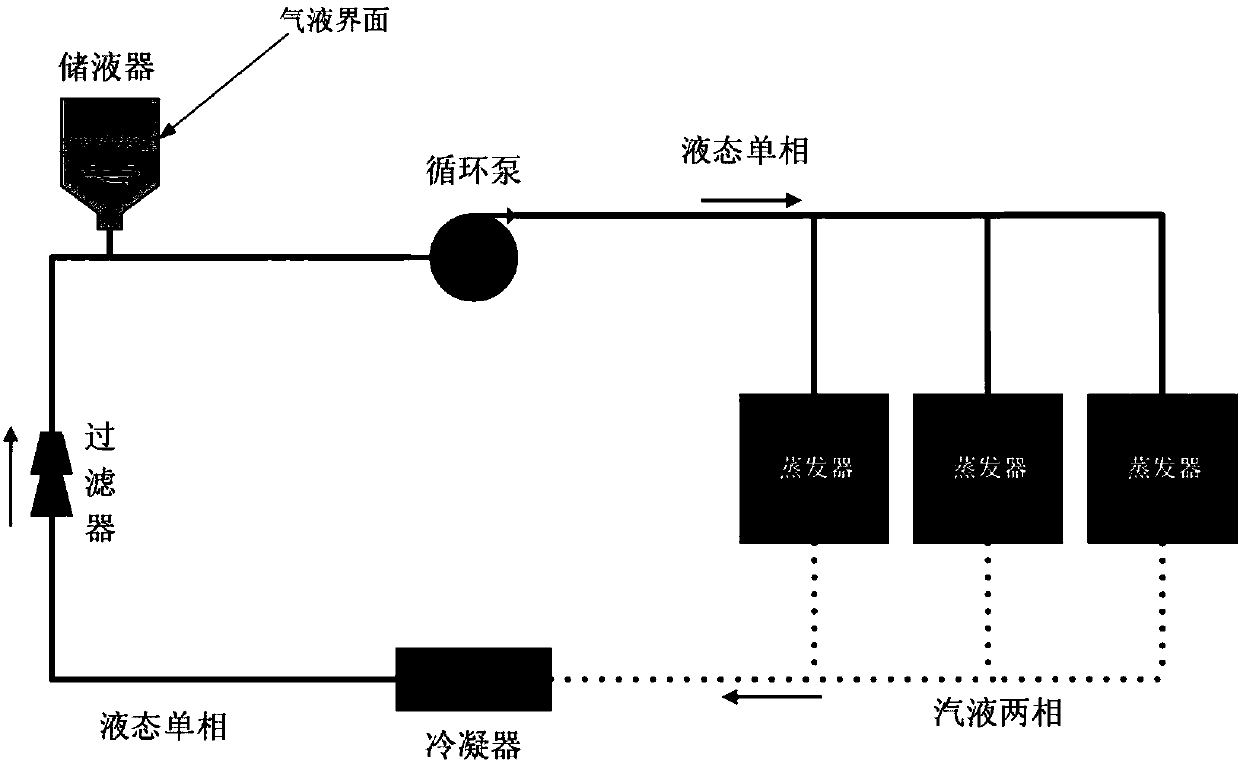

A temperature control device and fluid circuit technology, applied in the direction of temperature control, temperature control, non-electric variable control, etc., using electric methods, can solve the problems of difficult temperature control, large energy consumption, uneven heating, etc., and achieve response time Short, energy-saving, fast-response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

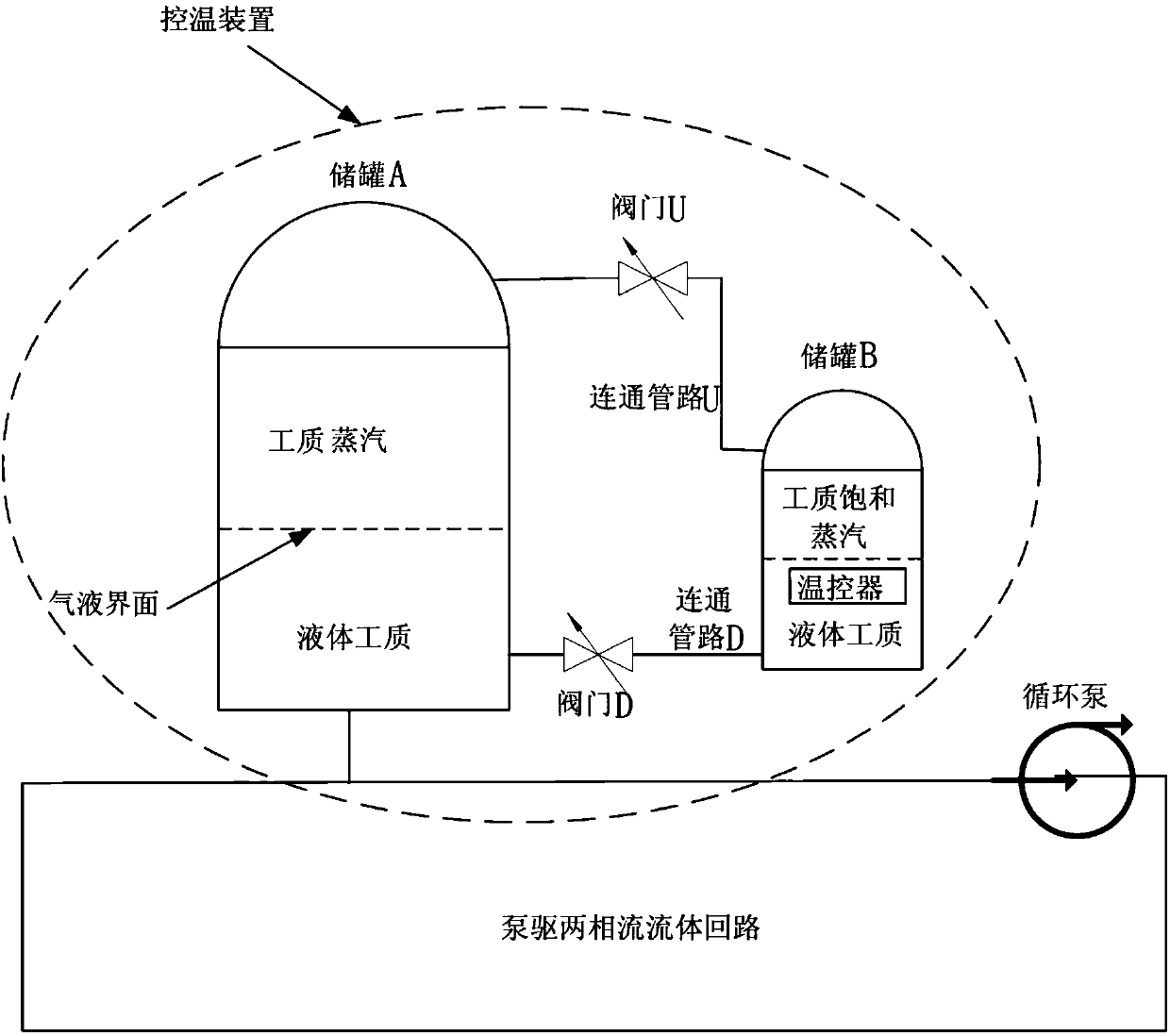

[0019] The invention provides a two-stage temperature control device for a pump-driven two-phase fluid circuit, which separates the two functions of the temperature control of the original liquid reservoir in the pump-driven two-phase fluid circuit system and the compensation for the high and low temperature volume changes of the working medium, and realizes the Accurate control of system temperature.

[0020] The two-stage temperature control device used in the pump-driven two-phase fluid circuit is a liquid reservoir, which includes a large storage tank and a small storage tank, as well as associated pipelines and valves. The working quality in the large storage tank is determined by the volume of the two-phase circuit in the pump-driven two-phase fluid circuit system and the operating temperature range of the system. The volume of the large storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com