Position measurement system

A measurement system and optical system technology, applied in the field of position measurement systems, can solve problems such as long adjustment time, low efficiency, and restrictions on the productization process of displacement sensor lithography machines, so as to improve adjustment freedom, save measurement and calibration time, and reduce The effect of assembly and integration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

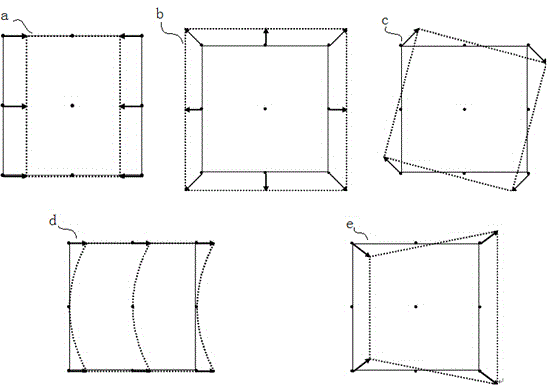

[0023] figure 1 is a schematic diagram of the structure of a measurement marker used in a position measurement system. Such as figure 1 As shown in , the measurement is marked as a set of rectangles, that is, rectangles of several shapes and sizes are arranged along the same direction, position, and angle.

[0024] figure 2 is a schematic diagram of the structure of measurement mark changes caused by manufacturing and assembly tolerances of optical components. The changing process of the measurement marks will be described below with reference to the accompanying drawings.

[0025] Such as figure 2 shown, where a figure represents the direction of measurement to figure 1 The central spot shown is the full-field zoom of the center in the direction of measurement. Specifically, the scaling adjustment in the direction of the arrow can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com