Vertically-discrete dual-electrode distributed micro-gyroscope and manufacturing method thereof

A micro-gyroscope, distributed technology, used in gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc. The effect of realizing full angle control and reducing parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

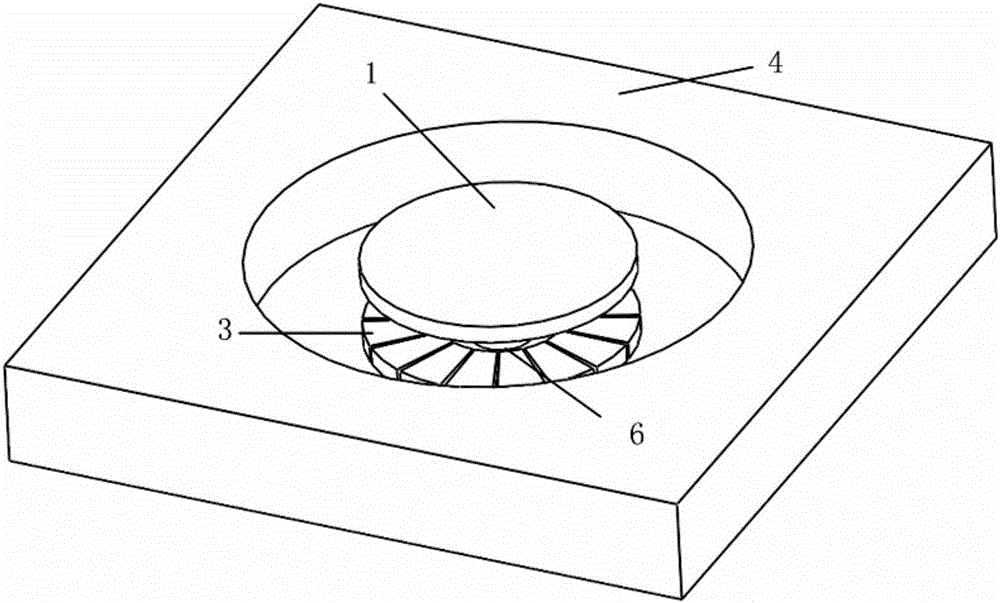

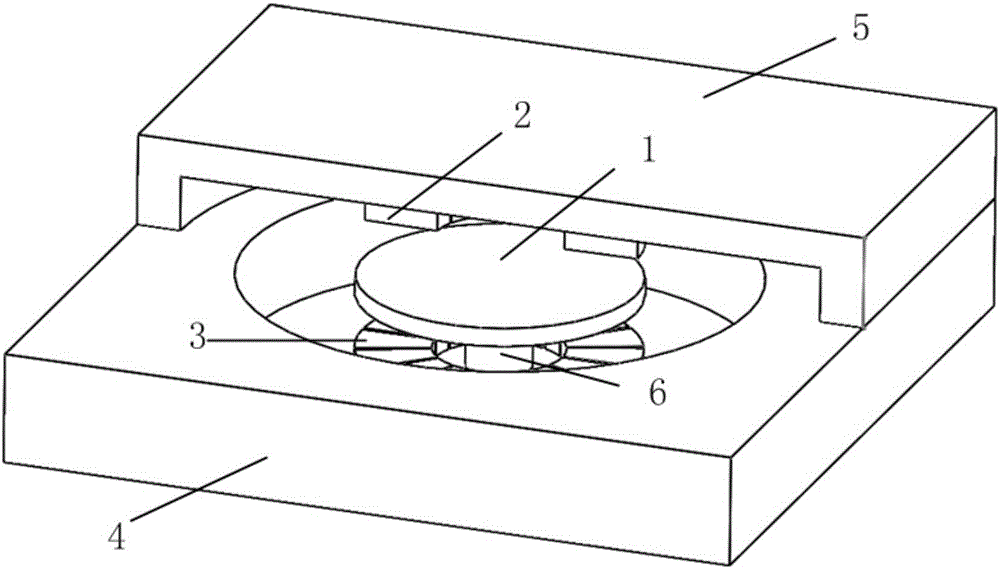

[0047] Such as Figure 1(a)-Figure 1(c) As shown, the present embodiment provides a two-electrode distributed miniature disc resonator gyroscope with upper and lower separation, including:

[0048] A disk-shaped micro-resonator 1;

[0049] Sixteen evenly distributed upper electrodes 2;

[0050] Sixteen evenly distributed lower electrodes 3;

[0051] A monocrystalline silicon substrate 4;

[0052] a glass substrate 5;

[0053] A central fixed support column 6; wherein:

[0054] One end of the central fixed support column 6 is connected to the monocrystalline silicon substrate 4, and the other end of the central fixed support column 6 is connected to the micro-resonator 1 (as shown in FIG. 1(a));

[0055] Sixteen uniformly distributed upper electrodes 2 are arranged on the surface of the glass substrate 5 (as shown in FIG. 1(b)), and are evenly distributed on the upper side of the micro-resonator 1 (as shown in FIG. c)); sixteen uniformly distributed lower electrodes 3 are ...

Embodiment 2

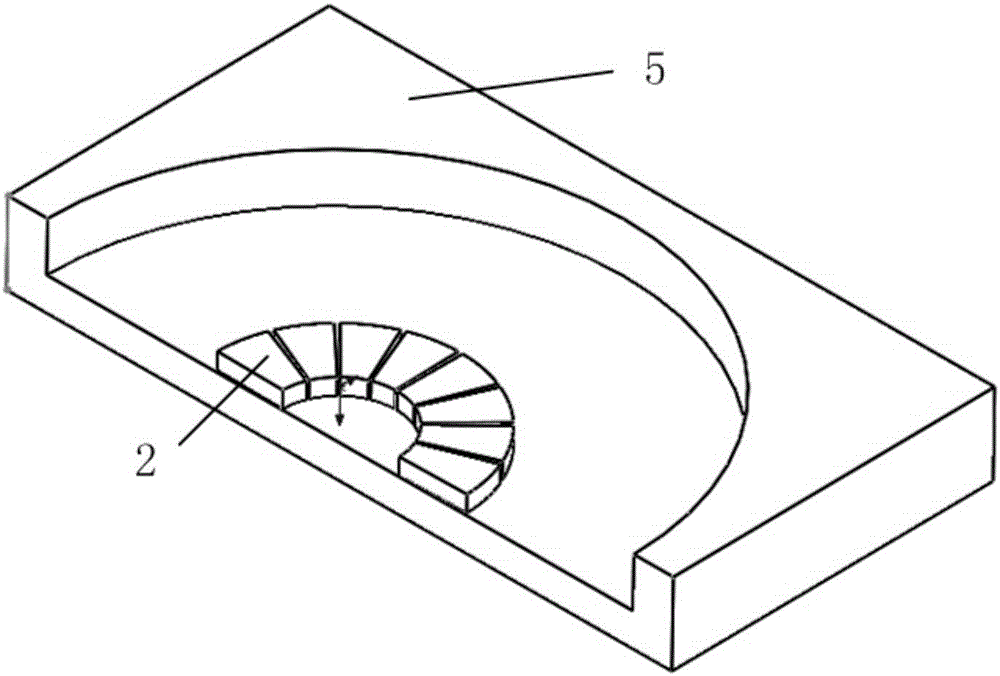

[0067] Such as Figure 2(a)-Figure 2(c) As shown, the present embodiment provides a two-electrode distributed micro-ring resonant gyroscope separated up and down, including:

[0068] A ring-shaped micro-resonator 1;

[0069] Sixteen evenly distributed upper electrodes 2;

[0070] Sixteen evenly distributed lower electrodes 3;

[0071] A monocrystalline silicon substrate 4;

[0072] a glass substrate 5;

[0073] A central fixed support column 6; wherein:

[0074] One end of the central fixed support column 6 is connected to the monocrystalline silicon substrate 4, and the other end of the central fixed support column 6 is connected to the micro-resonator 1 (as shown in Figure 2(a)); 16 The uniformly distributed upper electrodes 2 are arranged on the surface of the glass substrate 5 (as shown in Figure 2(b)), and are evenly distributed on the upper side of the micro-resonator 1 (as shown in Figure 2(c) shown); sixteen uniformly distributed lower electrodes 3 are arranged o...

Embodiment 3

[0082] Such as Figure 3(a)-Figure 3(c) As shown, the present embodiment provides a dual-electrode distributed miniature multi-ring resonant gyroscope separated up and down, including:

[0083] A multi-ring micro-resonator 1;

[0084] Sixteen evenly distributed upper electrodes 2;

[0085] Sixteen evenly distributed lower electrodes 3;

[0086] A monocrystalline silicon substrate 4;

[0087] a glass substrate 5;

[0088] A central fixed support column 6; wherein:

[0089] One end of the central fixed support column 6 is connected to the monocrystalline silicon substrate 4, and the other end of the central fixed support column 6 is connected to the micro-resonator 1 (as shown in Figure 3(a)); 16 The uniformly distributed upper electrodes 2 are arranged on the surface of the glass substrate 5 (as shown in Figure 3(b)), and are evenly distributed on the upper side of the micro-resonator 1 (as shown in Figure 3(c) shown); sixteen uniformly distributed lower electrodes 3 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com