Ultra-low-noise mining local fan

A local ventilation and ultra-low noise technology, which is applied to the parts of the pumping device for elastic fluid, mechanical equipment, machines/engines, etc., can solve the problems of high motor speed, large aerodynamic noise, and general noise reduction effect. Achieve the effects of reducing radiation noise, short maintenance time, and maintaining noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

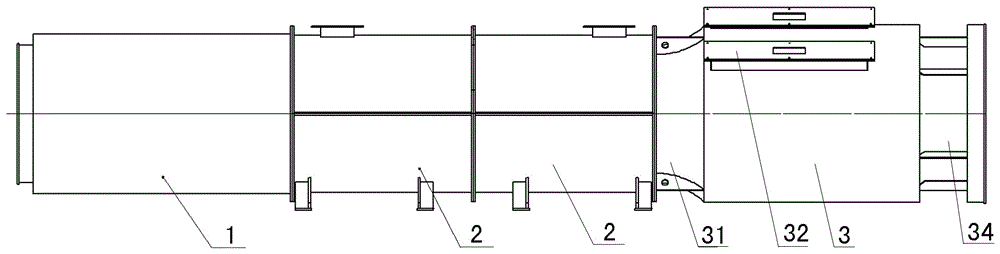

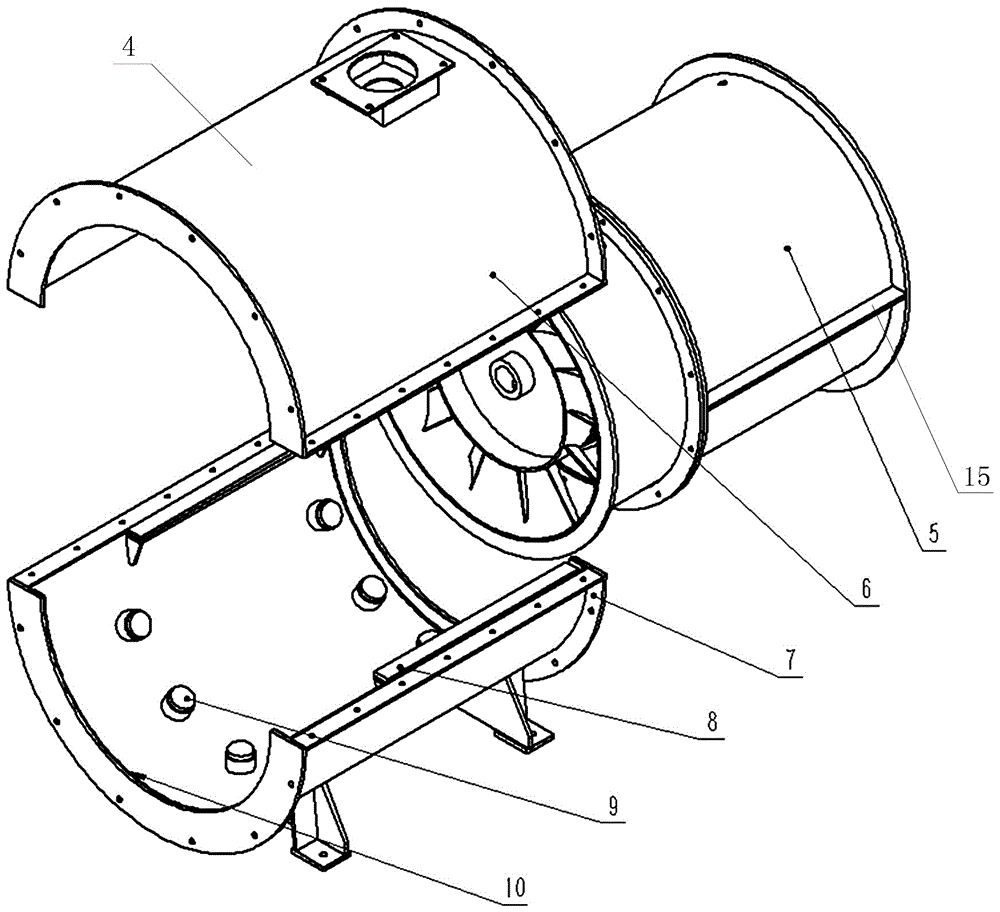

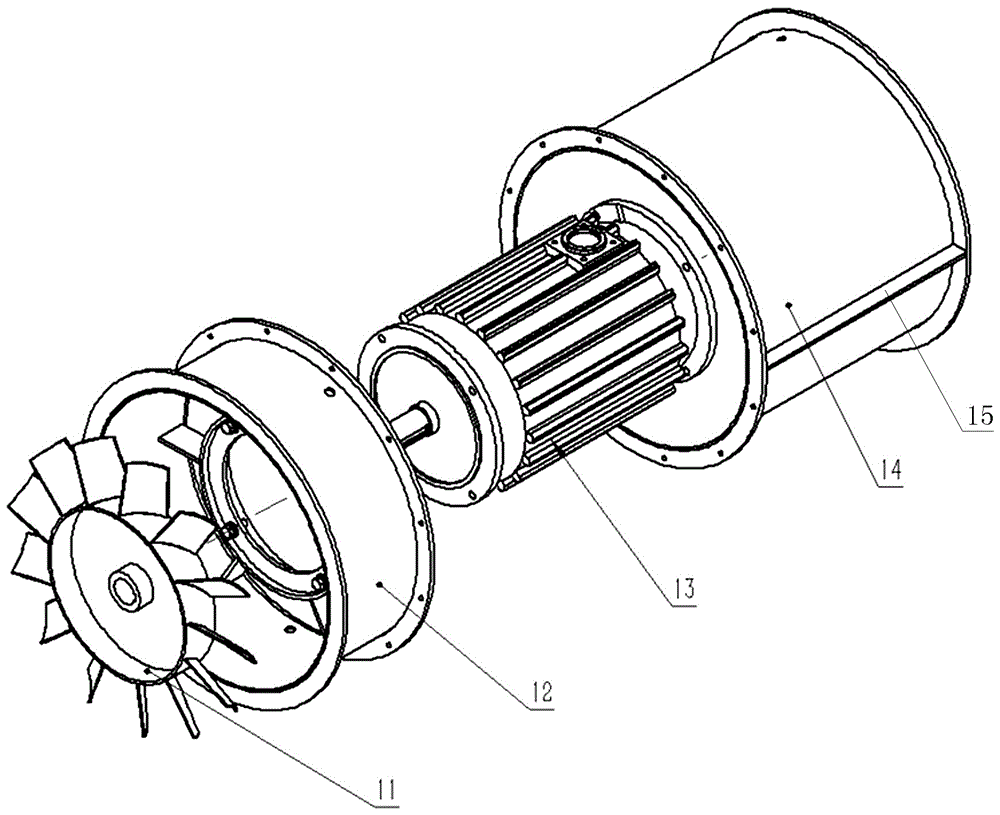

[0017] figure 1 It is a schematic diagram of an ultra-low-noise mining local fan equipped with two-stage main machine 2; figure 2 It is a schematic structural view of the main unit 2 of the ultra-low noise mine local ventilator according to the embodiment of the present invention; image 3 yes figure 2 Schematic diagram of the structure of the motor 13, the impeller 11, and the inner shell 5; the ultra-low noise mining local fan of the present invention includes an outlet muffler 1, a main body 2, and an inlet muffler 3, and is characterized in that: the main body 2 includes a motor 13, Impeller 11, inner casing 5, outer casing 4, described inner casing 5 comprises front inner casing 12, rear inner casing 14, and described casing 4 includes upper casing 6, lower casing 7, and there is in front inner casing 12 The impeller 11 has a motor 13 in the rear inner casing 14, and a flange is arranged on the motor 13. The front inner casing 12 and the rear inner casing 14 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com