Method for judging foam segment of coalbed methane shaft

A coalbed methane well and foam technology, which is applied in the field of judging the foam section of coalbed methane wellbore, can solve the problems of affecting the total production, reservoir pressure release reservoir damage, and large bottom hole pressure calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

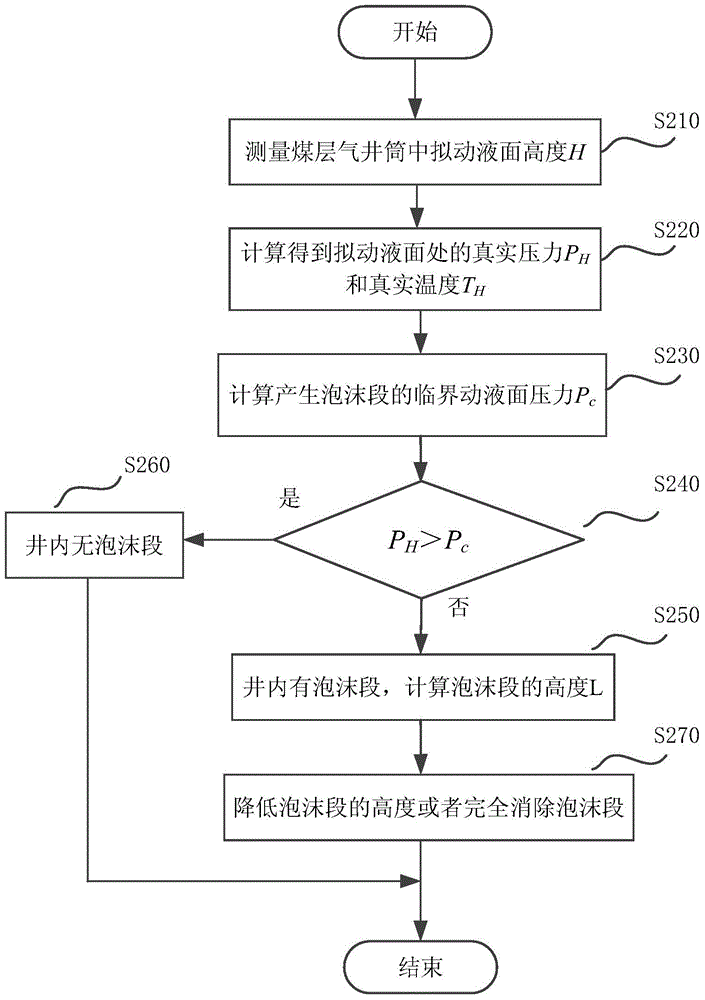

[0043] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

[0044] First, the application environment of the present invention will be described. figure 1It is a schematic diagram of the foam section above the dynamic liquid level of the casing annulus of a coalbed gas well. In a coalbed methane wellbore, the tubing 101 is used to discharge liquid, and the casing 104 is used to discharge gas. The liquid in the oil-jacket annulus 102 is basically static, and the coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com