Quantitative interpretation method for production profile of horizontal gas well

A production profile and quantitative interpretation technology, applied in measurement, earthwork drilling, wellbore/well components, etc., can solve the problem of irregular wellbore trajectory, low test success rate, and easy wear of rotameters or probes in horizontal wells Or sand stuck and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing.

[0061] This embodiment provides a method for quantitatively interpreting the production profile of a horizontal gas well, which includes the following steps:

[0062] The first step is to measure the temperature, pressure profile and liquid holdup data of the production interval of the horizontal gas well by using the coiled tubing + storage test instrument;

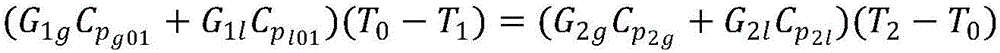

[0063] The second step is to calculate the mass flow rate of natural gas and liquid downstream of the production well section according to the gas production rate and liquid production rate at the wellhead, and establish fluid flow into the wellbore and mix with the fluid in the wellbore from the position of the first perforation cluster near the wellhead The energy conservation model in the process.

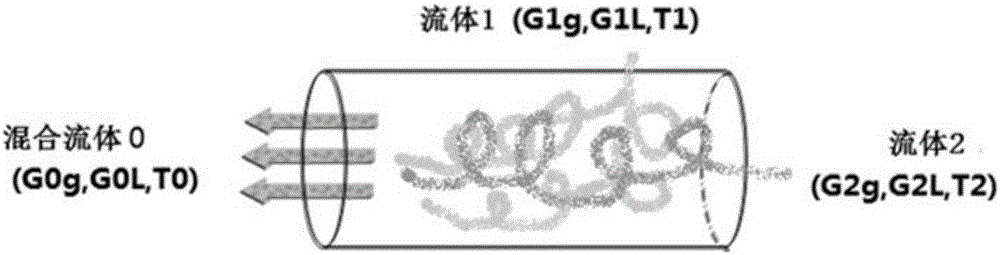

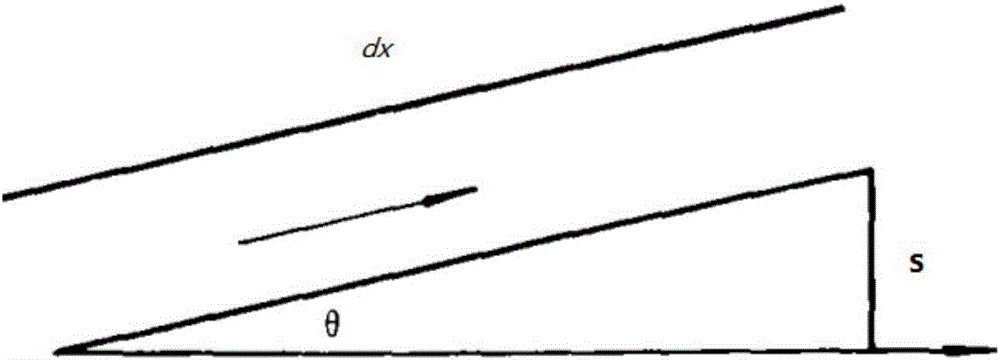

[0064] Such as figure 1 As shown, firstly, the temperature and pressure field near a single perforated section is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com