Horizontal well coiled tube drilling plug tubular column

A technology for horizontal wells and tubing, which is applied in the field of unconventional oil and gas exploration and development. It can solve the problems of long plug removal time and insufficient drilling pressure in the horizontal section, and achieve the effects of stable drilling process, improved efficiency and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

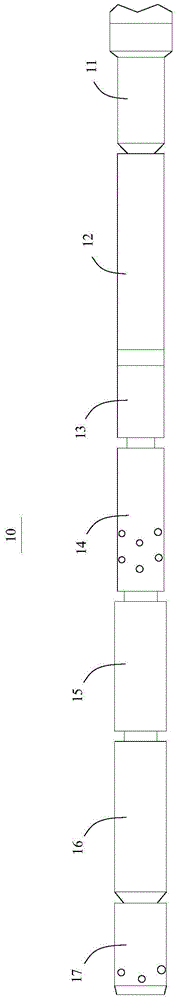

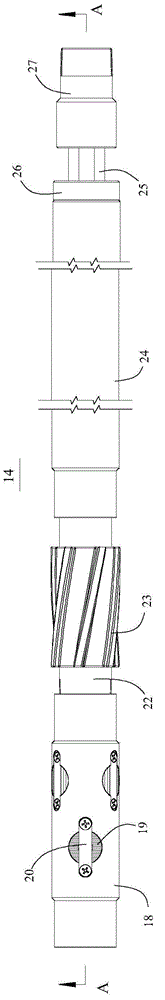

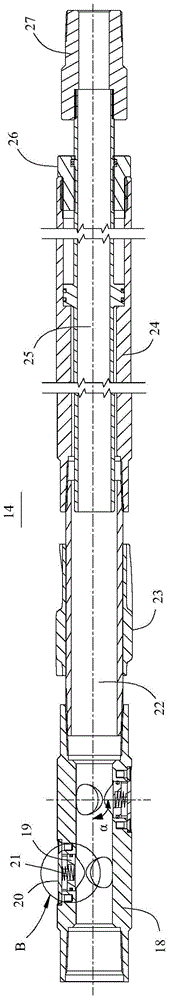

[0029] Such as figure 1 As shown, the coiled tubing drill string 10 of the embodiment of the present invention includes a grinding shoe 11 for drilling bridge plugs, a motor 12 drivingly connected to the grinding shoe 11, and a motor head 13 fixedly connected to the motor 12 , the anchor press device 14 fixedly connected with the motor head 13, the oscillator 15 fixedly connected with the anchor press device 14, the jar 16 fixedly connected with the oscillator 15 and the continuous Oil pipe joint 17. After the coiled tubing plug string 10 of the horizontal well is lowered to a predetermined position in the casing of the horizontal well, liquid under pressure is input into the plug string 10 . The anchoring and pressurizing device 14 is in the working state and the drill plug string 10 is anchored, and the liquid can drive the motor 12 to rotate, and then the motor 12 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com