Window screen mesh as well as preparation method and application thereof

A screen mesh and warp technology, applied in fabrics, perforated fabrics, textiles, etc., can solve the problems of PM2. The screen mesh has stable structure, good ventilation performance and high porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

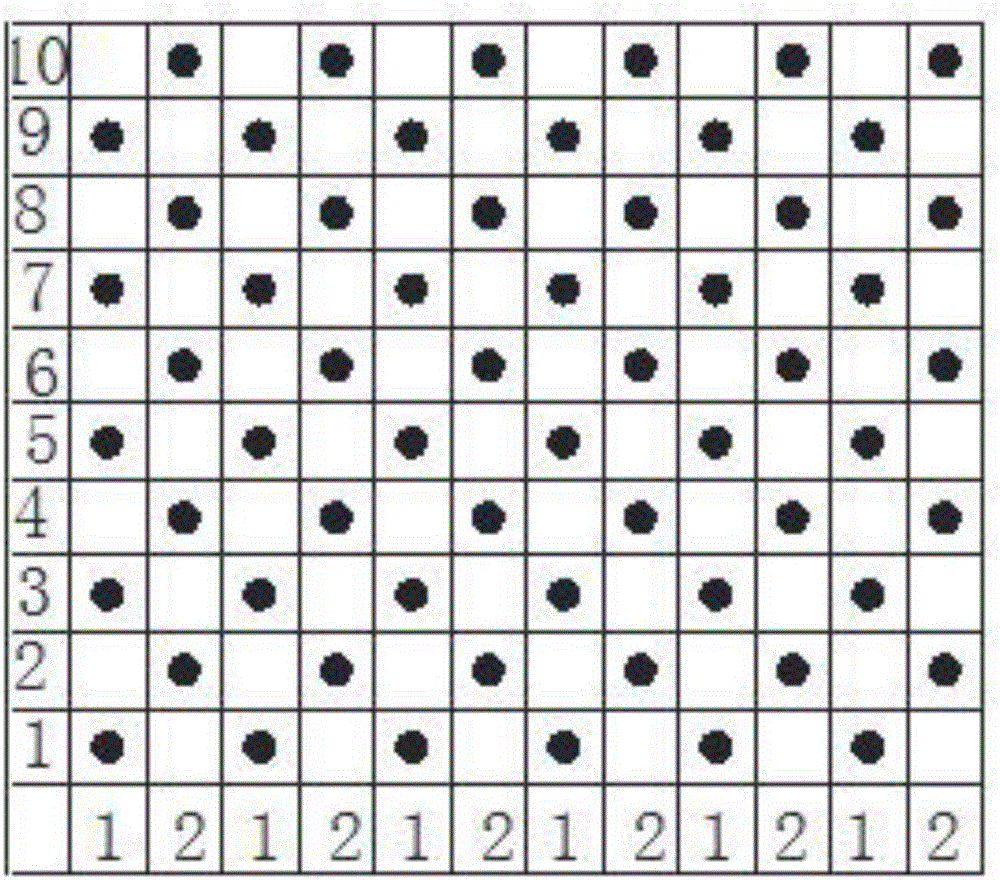

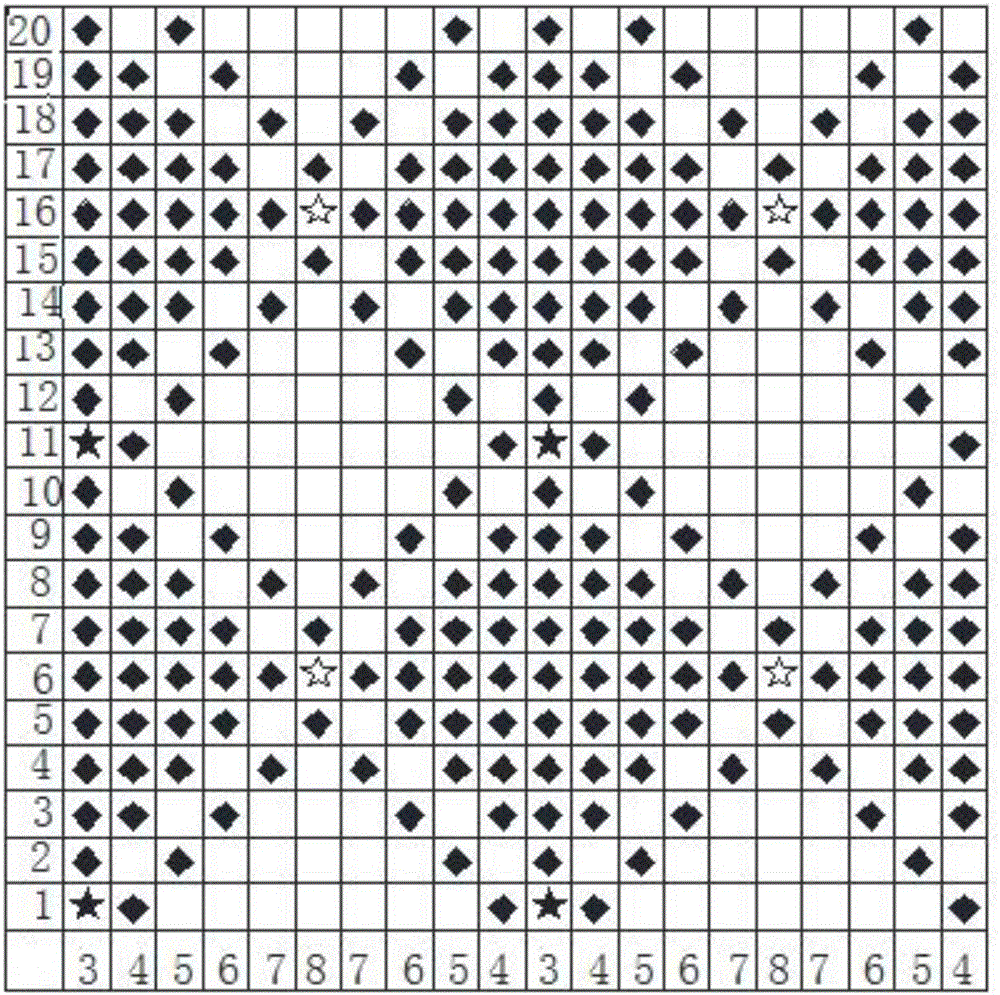

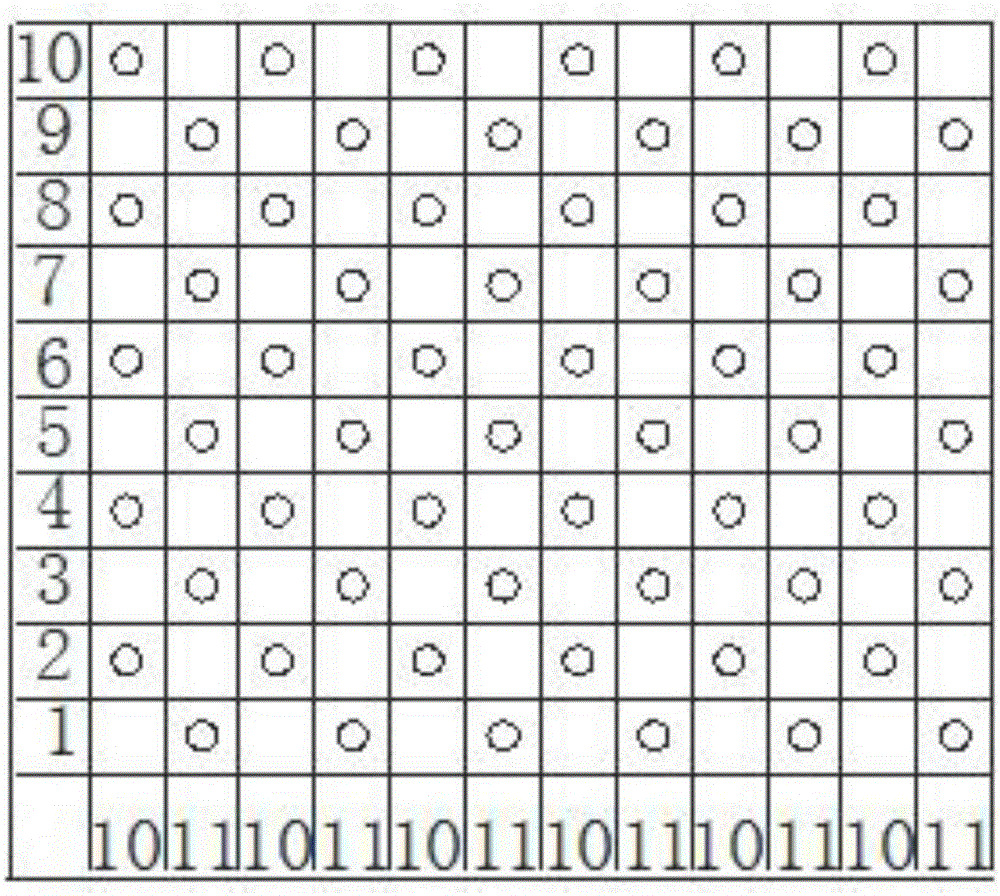

[0056] The screen window net weaving method in which the upper net weaving process is plain weave, the middle net is 12*10 weaving structure, and the lower net is plain weave will further illustrate the present invention, but does not limit the scope of the present invention.

[0057] according to Figure 1-3 The weaving structure shown weaves the screen mesh on a rapier loom. Figure 1-3 The weaving mode and the weaving connection between the upper net, the middle net and the lower net of the screen netting described in embodiment 1 are shown.

[0058] exist Figure 1-3 middle:

[0059] ●Indicates that the warp of the upper net is above the weft,

[0060] ◆Indicates that the warp of the middle net is above the weft,

[0061] ○ indicates that the warp of the lower net is above the weft, and no point indicates that the warp is below the weft.

[0062] represents the intersection of the upper-level net and the middle-level net, and

[0063] ☆Indicates the intersection of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com