A kind of method that dichloromethane prepares trichlorethylene

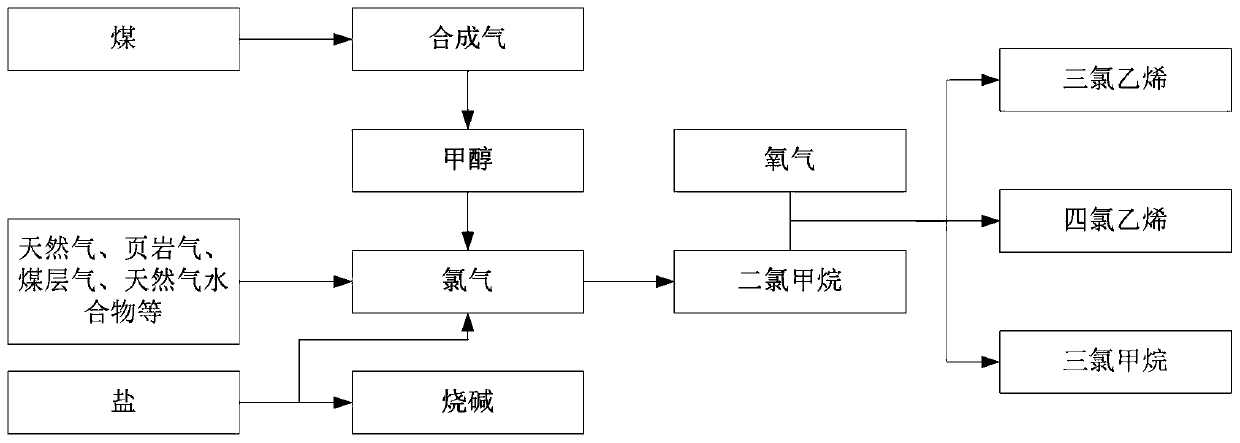

A technology of dichloromethane and trichloroethylene, which is applied in the field of preparation of trichloroethylene, can solve the problems of not clearly pointing out trichloroethylene, extrusion of profit space, high energy consumption of calcium carbide, etc., so as to avoid high energy consumption and high pollution problems, reduced production costs, and the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

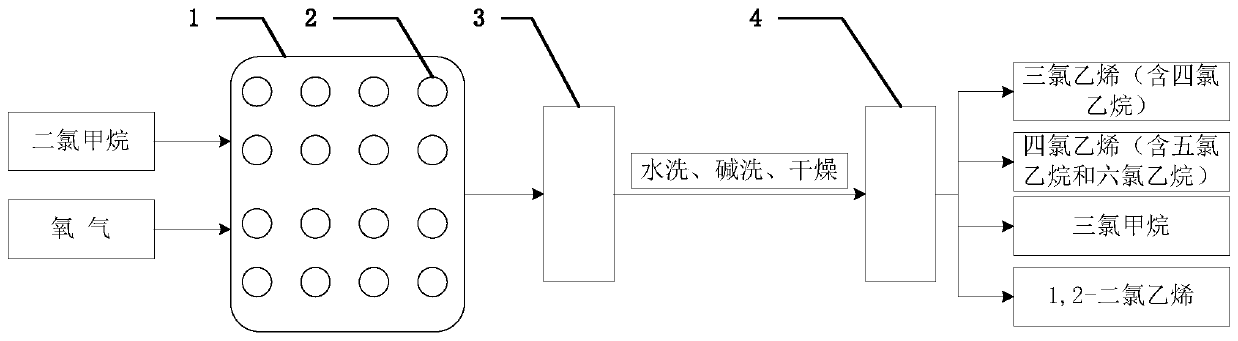

Embodiment 1

[0055] 将二氯甲烷(加热气化)和氧气按照摩尔比为1:0.5进行混合,通入未装填催化剂的反应器中,在600℃,1atm下进行反应。反应流出物经降温,水洗碱洗除去氯化氢后,进行组成分析,计算得知二氯甲烷转化率约为2%,三氯乙烯(含四氯乙烷)选择性约为27%,四氯乙烯(含五氯乙烷和六氯乙烷)选择性约为3%,三氯甲烷选择性约为52%,1,2-二氯乙烯选择性约为12%。

Embodiment 2

[0057] 将锶的前驱体化合物制成水溶液,加入硅胶搅拌均匀,然后烘干、焙烧制得催化剂,将二氯甲烷(加热气化)和氧气按照摩尔比为1:0.5进行混合,通入装有催化剂的反应器中,在600℃,1atm下进行反应,反应流出物经降温,水洗碱洗除去氯化氢后,进行组成分析,计算得知二氯甲烷转化率约为35%,三氯乙烯(含四氯乙烷)选择性约为45%,四氯乙烯(含五氯乙烷和六氯乙烷)选择性约为5%,三氯甲烷选择性约为40%,1,2-二氯乙烯选择性约为8%。

Embodiment 3

[0059] 将锶和钨的前驱体化合物制成水溶液,加入硅胶搅拌均匀,然后烘干、焙烧制得催化剂,将二氯甲烷(加热气化)和氧气按照摩尔比为1:0.5进行混合,通入装有催化剂的反应器中,在600℃,1atm下进行反应。反应流出物经降温,水洗碱洗除去氯化氢后,进行组成分析,计算得知二氯甲烷转化率约为48%,三氯乙烯(含四氯乙烷)选择性约为42%,四氯乙烯(含五氯乙烷和六氯乙烷)选择性约为10%,三氯甲烷选择性约为36%,1,2-二氯乙烯选择性约为7%。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com