Preparation method of slow controlled release fertilizer for flowering peach

A technology of controlled-release fertilizer, betao, which is applied in the field of preparation of slow-controlled release fertilizer for betao, can solve the problems of low fertilizer utilization rate, achieve the effect of saving fertilization cost, improving ornamental economic benefits, and using less amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

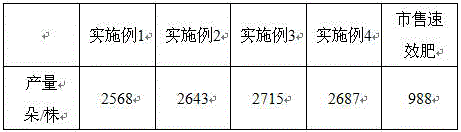

Examples

Embodiment 1

[0016] A kind of preparation method of slow and controlled release fertilizer for green peach, comprises the following steps:

[0017] Step 1, in parts by weight, add 10 parts of urea, 2 parts of sodium citrate, and 4 parts of humic acid to 10 parts of water, adjust the pH to 8.0-9.0, add 3 parts of formaldehyde solution, heat up to 75 ° C for 2 hours, Then add 1 part of oxidized starch and 2 parts of hydrogenated vegetable oil, adjust the pH to 4.0-5.0, raise the temperature to 85°C for 2 hours, adjust the pH to 6.0-7.0, and obtain mixture A;

[0018] Step 2, in parts by weight, take 3 parts of sodium alginate and 1 part of gelatin, add them to water, heat to 40°C, stir and keep warm for 2 hours, then add 2 parts of potassium nitrate, 3 parts of diammonium hydrogen phosphate, and 1 part of magnesium sulfate heptahydrate , 0.5 part of vitamin B family, 0.1 part of nicotinamide, 0.01 part of amino acid, 0.4 part of corn flour, 0.1 part of chitosan, 0.01 part of lecithin, mixed ...

Embodiment 2

[0022] A kind of preparation method of slow and controlled release fertilizer for green peach, comprises the following steps:

[0023] Step 1, in parts by weight, add 16 parts of urea, 3 parts of sodium citrate, and 7 parts of humic acid to 13 parts of water, adjust the pH to 8.0-9.0, add 5 parts of formaldehyde solution, heat up to 80 ° C for 2 hours, Then add 2 parts of oxidized starch and 3 parts of hydrogenated vegetable oil, adjust the pH to 4.0-5.0, heat up to 90°C for 2 hours, and adjust the pH to 6.0-7.0 to obtain mixture A;

[0024] Step 2, in parts by weight, add 6 parts of sodium alginate and 2 parts of gelatin to water, heat to 45°C, stir and keep warm for 2 hours, then add 7 parts of potassium nitrate, 4 parts of diammonium hydrogen phosphate, and 2 parts of magnesium sulfate heptahydrate , 0.7 part of vitamin B family, 0.3 part of nicotinamide, 0.05 part of amino acid, 0.8 part of corn flour, 0.3 part of chitosan, 0.04 part of lecithin, mixed to obtain mixture B;...

Embodiment 3

[0028] A kind of preparation method of slow and controlled release fertilizer for green peach, comprises the following steps:

[0029] Step 1, in parts by weight, add 12 parts of urea, 4 parts of sodium citrate, and 8 parts of humic acid to 16 parts of water, adjust the pH to 8.0-9.0, add 7 parts of formaldehyde solution, heat up to 75 ° C for 2 hours, Then add 3 parts of oxidized starch and 5 parts of hydrogenated vegetable oil, adjust the pH to 4.0-5.0, heat up to 85°C for 2 hours, and adjust the pH to 6.0-7.0 to obtain mixture A;

[0030] Step 2, in parts by weight, take 8 parts of sodium alginate and 3 parts of gelatin and add them to water, heat to 40°C and stir for 2 hours, then add 7 parts of potassium nitrate, 6 parts of diammonium hydrogen phosphate, and 4 parts of magnesium sulfate heptahydrate , 0.9 part of vitamin B family, 0.3 part of nicotinamide, 0.05 part of amino acid, 1.2 part of corn flour, 0.6 part of chitosan, 0.05 part of lecithin, mixed to obtain mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com