Fire-resistant rock wool board and preparing method thereof

A rock wool board, fire-resistant technology, applied in glass manufacturing equipment, manufacturing tools, etc., to achieve the effect of improving stability, high fire resistance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A fire-resistant rock wool board, the chemical composition of the rock wool board includes Fe 2 o 3 and Al 2 o 3 , Fe 2 o 3 The mass of the rock wool board accounts for 13% to 18% of the total mass of the rock wool board, Al 2 o 3 The mass of the rock wool board accounts for 12% to 15% of the total mass of the rock wool board. The chemical composition of the rock wool board also includes SiO 2 , CaO and MgO, among which SiO 2 The mass of CaO accounts for 30% to 45% of the total mass of the rock wool board, the mass of CaO accounts for 10% to 20% of the total mass of the rock wool board, and the mass of MgO accounts for 3% to 8% of the total mass of the rock wool board.

[0022] The acidity coefficient of the rock wool board is 2.5-3. The organic matter content of the rock wool board is 0.5-1.5%.

[0023] The components of the rock wool board include: basalt, dolomite, hematite, and bauxite, and the mass parts of each component are: 60-70 basalt, 10-20 dolomite...

Embodiment 2

[0025] The preparation method of the rock wool board described in Example 1: the components of the rock wool board include: basalt, dolomite, hematite, bauxite, and the mass parts of each component are: basalt 60-70, dolomite Stone 10-20, hematite 10-20, bauxite 5-10, the preparation steps of rock wool board are:

[0026] 1) Mix basalt, dolomite, hematite, and bauxite evenly in parts by mass, and then input the mixture into an electric furnace and melt it at a high temperature of 1500°C to 1800°C to form a molten slurry;

[0027] 2) The molten slurry flows out from the flow port of the furnace body, and is spun at high speed by a four-roller centrifuge to form rock wool fibers;

[0028] 3) Collect, solidify and shape rock wool fibers to make rock wool products.

Embodiment 3

[0030] Further optimization on the basis of the rock wool board described in Example 2.

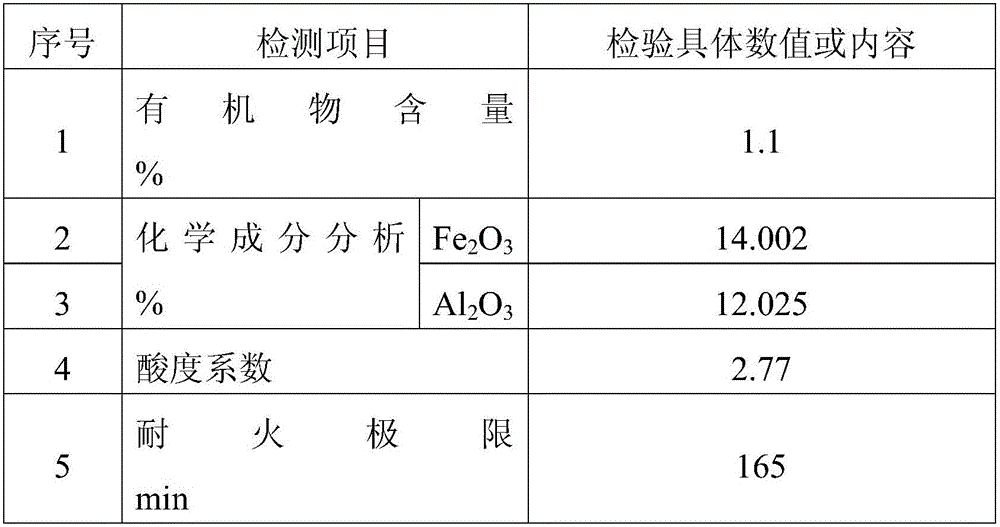

[0031] Take 640kg of basalt, 100kg of dolomite, 80kg of bauxite, and 180kg of hematite. After mixing the above raw materials evenly, they are transported into an electric furnace through a conveyor belt and melted at a high temperature of 1500°C to form a melt. The molten body flows out through the flow port of the furnace body, and is spun into fibers under the centrifugal force of the four-roller centrifuge. The adhesive is evenly sprayed, and the cotton is spread by the flat cloth method, and the three-dimensional three-dimensional folding technology is adopted to solidify and form. The test result of the obtained rock wool board is:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com