Material supply device of straw briquetting machine

A straw briquetting machine and feeding device technology, applied to presses, manufacturing tools, etc., can solve the problems of low feeding efficiency, large dust on the work site, and harmful breathing of operators, and achieve less dust, large capacity, and efficient work. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

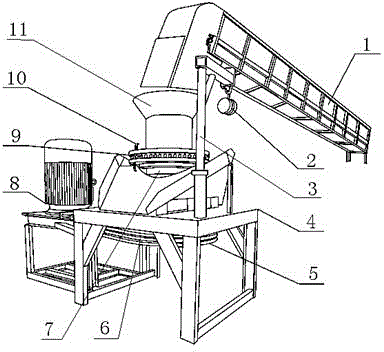

[0010] Depend on figure 1 Known, a kind of feeding device of straw briquetting machine is composed of auxiliary silo 1, side feeding pipe 2, motor 3, distribution hopper 4, pull plate 5, screw auger 6, observation port 7, material splitter 8, Central shaft 9, torsion bar 10 and handle 11 are formed. The upper end of the auger 1 is connected with the distribution hopper 4 and distributed on both sides of the distribution hopper 4, the auxiliary silos 1 are respectively arranged on both sides of the auger 6, connected with the distribution hopper 4 through the side conveying pipe 2, and the central shaft 9 is installed on the distribution hopper. On the hopper 4, the material splitter 8 is fixed on the central shaft 9, the torsion bar 10 is fixed on one end of the central shaft 9, and the handle 11 is connected with the torsion bar 10. When working, the material is lifted to the sub-hopper by the auger 6 4 position, when the material splitter 8 is in the middle position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com