Automatic precise clamp and production line for piston machining

A piston, automatic technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of high maintenance cost, high use cost, increased maintenance difficulty of structure and system, and achieve simplified structure and control system design. , The mechanical running path is single, and the effect of eliminating the hidden danger of positioning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

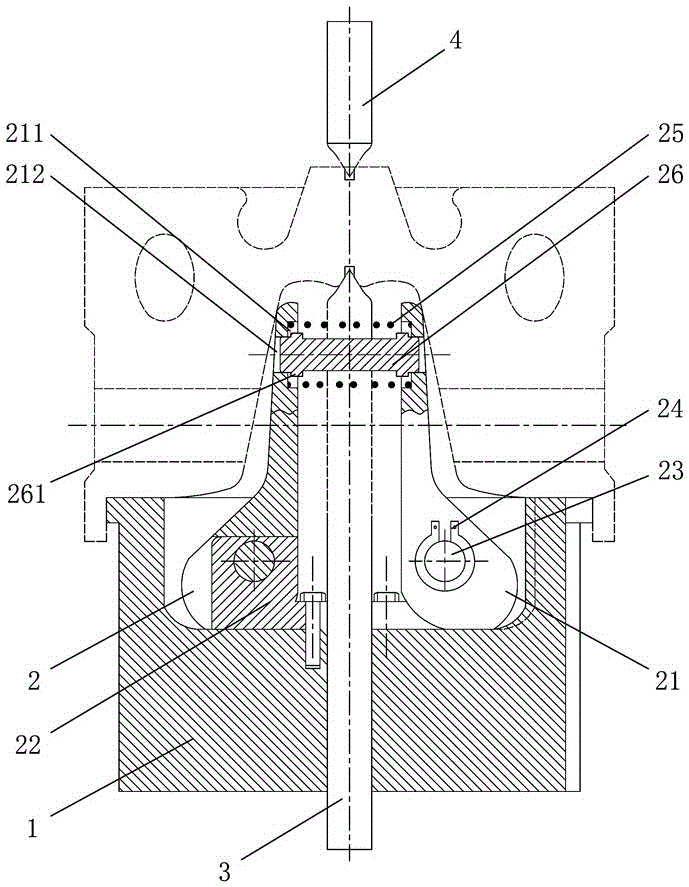

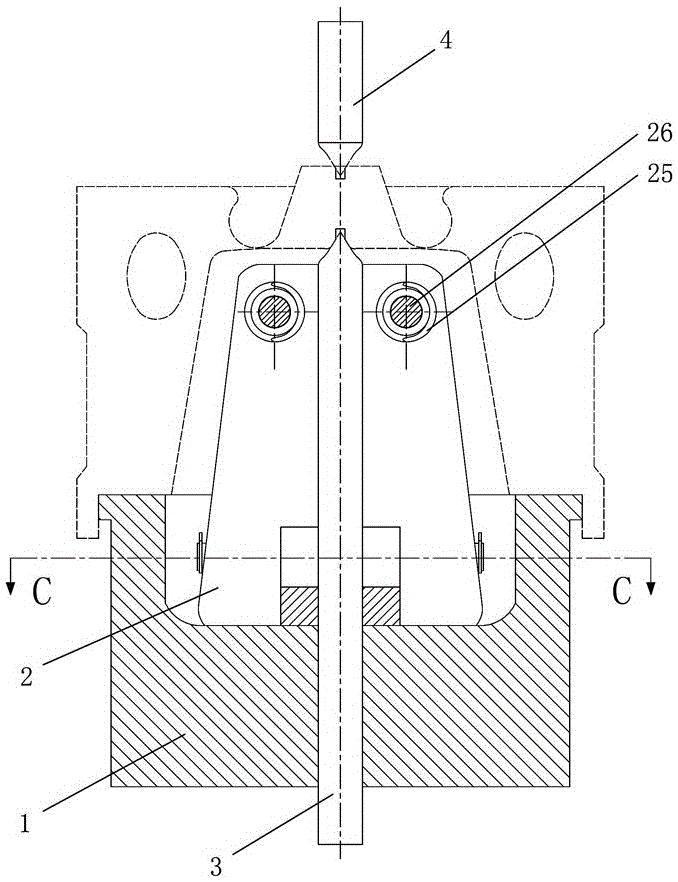

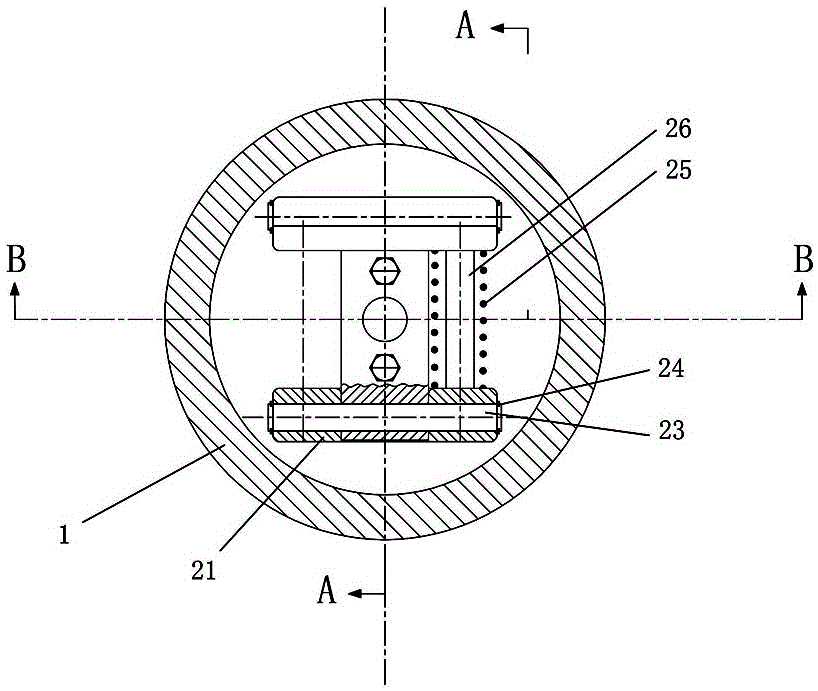

[0037] Figure 1 to Figure 3It shows the embodiment of the first automatic finishing fixture used for piston processing in the present invention. The automatic finishing fixture includes a stop plate 1 and a shift fork assembly 2. The mouth plate 1 is connected, and the fixture also includes a ejector rod 3 and a push rod 4 arranged coaxially with the mouth plate 1. Both the end of the ejector rod 3 and the end of the push rod 4 are provided with a conical top, and the top The material rod 3 is installed in the mouth plate 1 and the shift fork assembly 2, the push rod 4 is arranged above the ejector rod 3, and the conical top of the ejector rod 3 is opposite to the conical top of the push rod 4. The automatic finishing fixture for piston processing of the present invention provides a unique piston clamping method, which ensures that the piston processing surface can be well protected during the positioning and clamping process of the piston, and the main working surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com