Carbon-based mercury-removing absorbent and preparation method thereof

An adsorbent and mercury removal technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of complex preparation process of adsorbents and high cost of mercury removal, and achieve improved mercury removal capacity and micropore content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

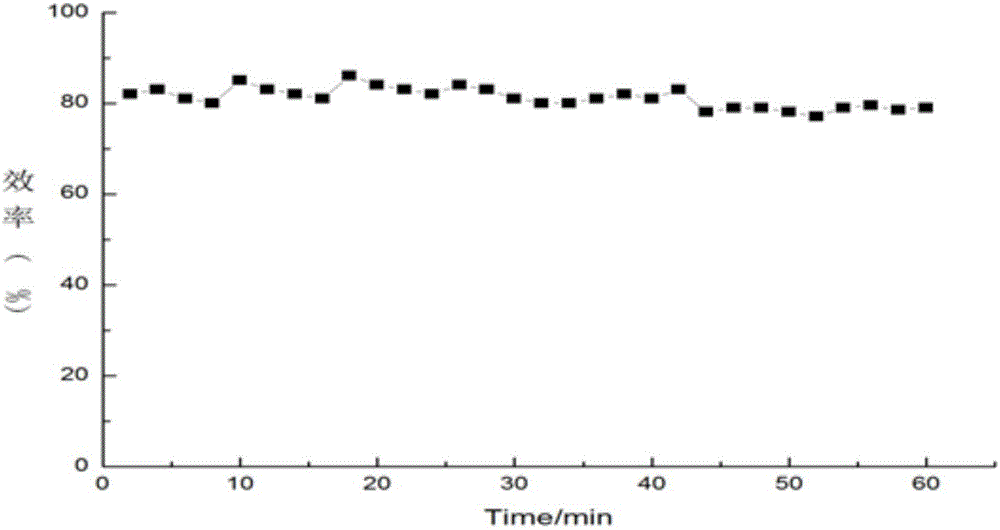

Examples

preparation example Construction

[0022] The invention provides a preparation method of a carbon-based mercury removal adsorbent, comprising:

[0023] A) mixing and etching fly ash and lye to obtain etched fly ash;

[0024] B) In an inert gas environment, mix the etched fly ash with metal halides and alkalis, and activate to obtain activated fly ash; the activation temperature is 700°C-800°C, and the activation time is 90-90°C. 120min;

[0025] C) Mixing and modifying the activated fly ash and the metal halide solution to obtain a carbon-based mercury-removing adsorbent.

[0026] The invention firstly mixes fly ash and lye and etches to obtain etched fly ash.

[0027] The fly ash in the present invention is the fly ash obtained from the combustion of coal in a power plant, and the inventor does not limit this, as long as those skilled in the art are familiar with it.

[0028] The fly ash is preferably pretreated, and the pretreatment specifically includes drying and sieving.

[0029] The drying is preferab...

Embodiment 1

[0060] The fly ash taken from the power plant was used as raw material, dried at 105°C for 8 hours to remove moisture, and passed through a 200-mesh sieve.

[0061] Take by weighing 10g potassium hydroxide, and add 25ml of ultrapure water and stir to make it dissolve completely; Take by weighing 2g fly ash and place in potassium hydroxide solution, make it mix evenly, wherein the mass ratio of potassium hydroxide and fly ash is 5: 1. The mixed solution was ultrasonically treated for 40 minutes, then poured into a sealed sample bottle, tightened, placed in a shaker, and shaken continuously for 12 hours, and then dried in a blast drying oven at a rate of 10°C / min to 105°C for 7 hours to constant weight to obtain the etched fly ash.

[0062] Put the dried mixed sample into a crucible, put it in a simulated flue, and under the protection of nitrogen in 500ml / min, load 2g potassium hydroxide, 1.5gZnCl 2 The fly ash was activated at 800°C for 120min. After cooling, the activated s...

Embodiment 2

[0066] The fly ash taken from the power plant was used as raw material, dried at 105°C for 9 hours to remove moisture, and passed through a 200-mesh sieve.

[0067] Take by weighing 8g sodium hydroxide, and add 25ml of ultrapure water and stir to make it dissolve completely; Take by weighing 2g fly ash and place in sodium hydroxide solution, make it mix evenly, wherein the mass ratio of sodium hydroxide and fly ash is 4: 1. The mixed solution was ultrasonically treated for 50 minutes, then poured into a sealed sample bottle, tightened, placed in a shaker, and shaken continuously for 12 hours, and then dried in a blast drying oven at a rate of 10°C / min to 105°C for 7 hours to constant weight to obtain the etched fly ash.

[0068] Put the dried mixed sample into a crucible, put it in a simulated flue, and under the protection of nitrogen in 500ml / min, load 2g calcium hydroxide, 1.5gZnCl 2 The fly ash was activated at 800°C for 120min. After cooling, the activated sample was wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com