Improved bra underwires, processing method thereof and bra product provided with same

A technology of steel rings and bras, applied in brassieres, applications, clothing, etc., to achieve the effects of strong tensile deformation resistance, good rubber elasticity, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

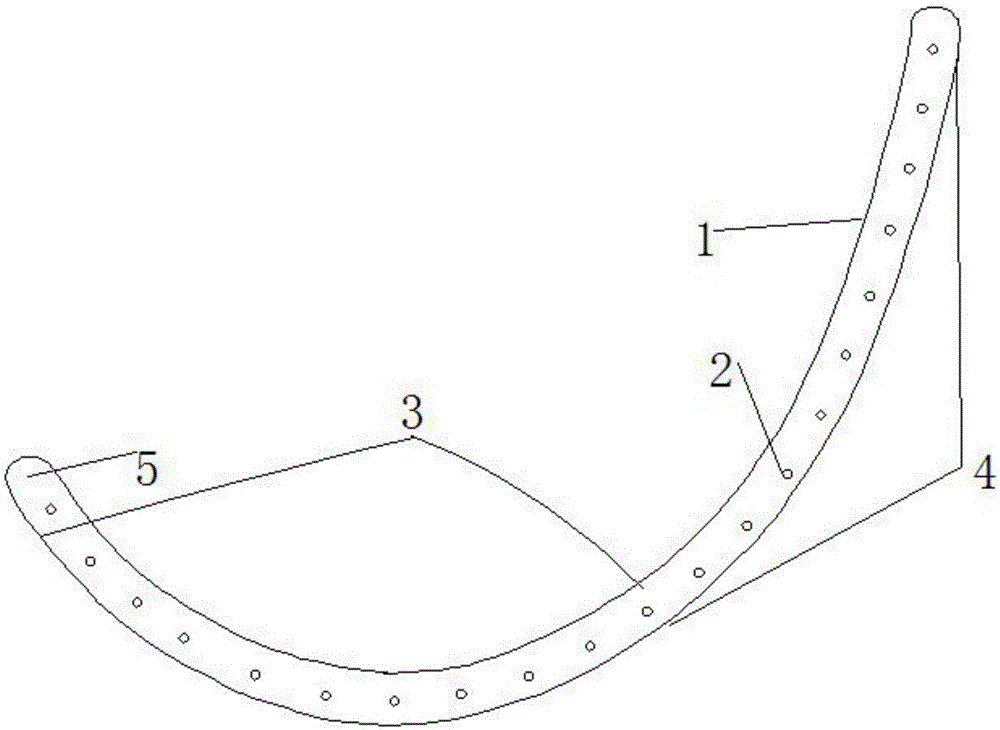

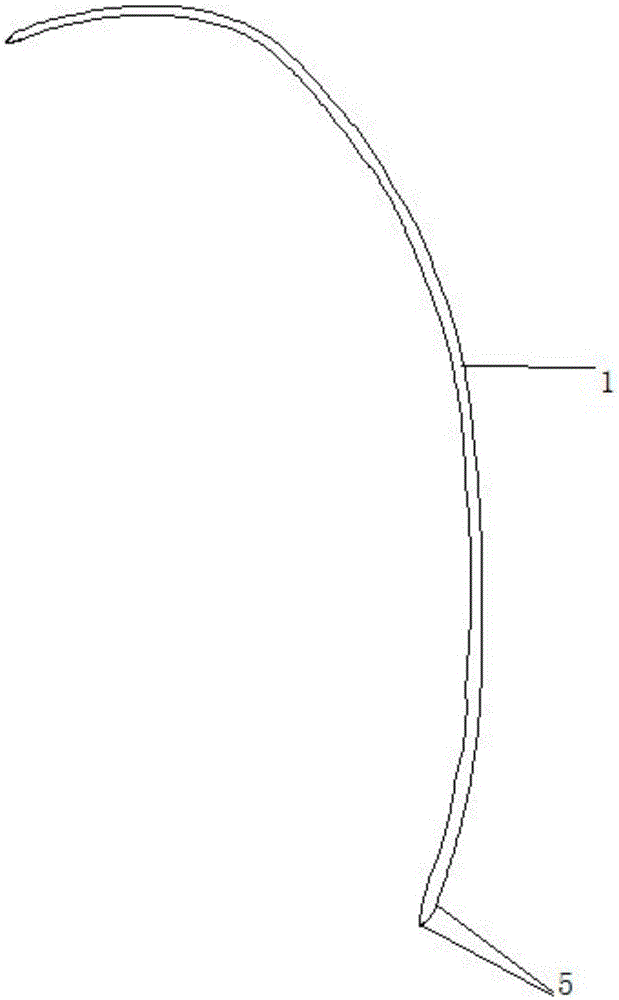

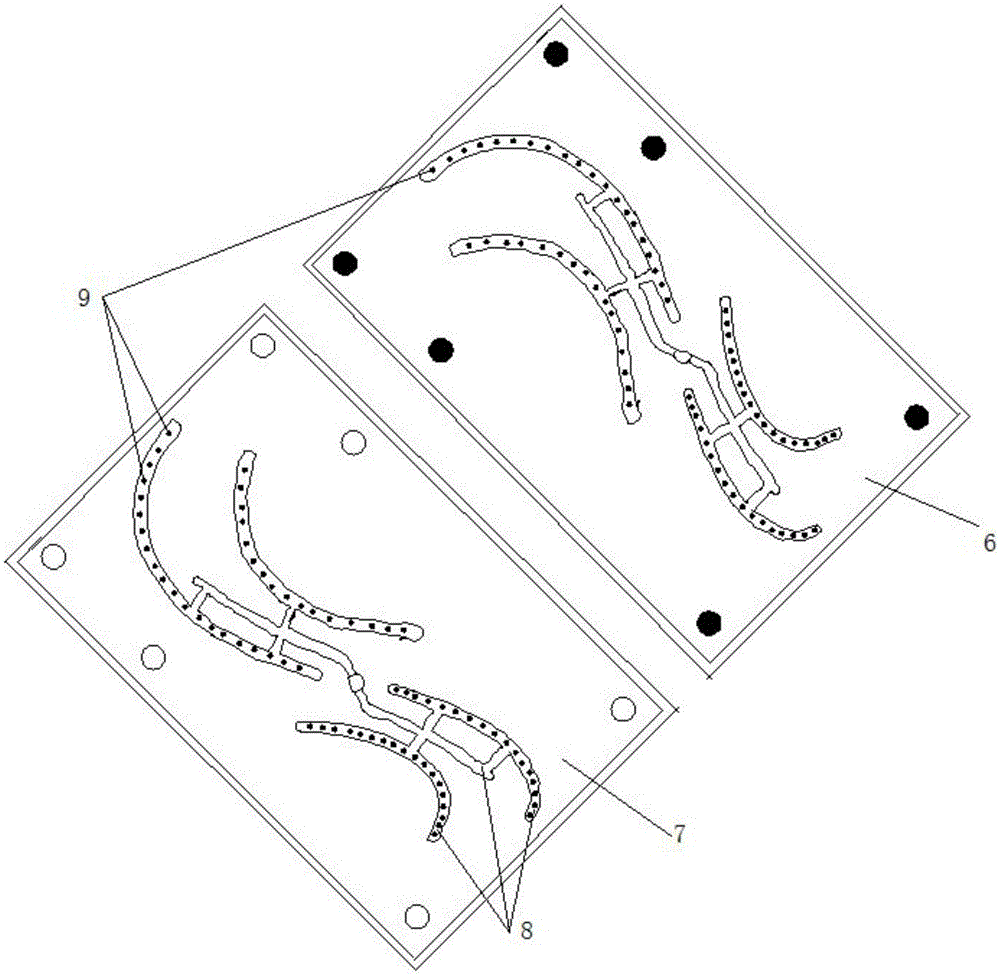

[0031] Embodiment 1: see Figure 1-3 , the improved bra steel ring of the present invention, the steel ring 1 is made of modified thermoplastic polyurethane elastomer after being injected into a mold, and the front and back sides of the steel ring 1 are correspondingly provided between one end and the other end. Relatively dense grooves 2, so that the inner and outer layers of the bra cup can be tightly embedded in the groove 2 after spraying glue, cold paste, and molding, so as to be connected and fixed with the steel ring 1; the groove 2 is a hole structure ; The steel ring 1 is an arc-shaped steel ring that can adapt to the shape of the human breast, and the length of the inner arc 3 near the inner side of the breast is 50-60% of the length of the outer arc 4 near the outer side of the breast; Both ends of the ring 1 are provided with flat extensions 5, and the length of the extensions 5 is 2-4% of the overall length of the steel ring 1; the modified thermoplastic polyureth...

Embodiment 2

[0036]Embodiment 2: the improved bra steel ring provided by this embodiment and its processing method, and the brassiere made of the improved bra steel ring, its overall technical scheme is basically the same as that of embodiment 1, the difference is that this embodiment provides The processing method of the improved bra steel ring, it comprises the steps:

[0037] (1) Preparation of modified thermoplastic polyurethane elastomer material: Add 48 parts of the measured copolyether into a four-neck flask, vacuumize and ventilate nitrogen, control the temperature at 100°C to remove moisture, add 33 parts of isocyanate and 3 parts of organotin, and Stir, pre-polymerize at 110°C for 1-2 hours, then add 16 parts of diol, 18 parts of urea-formaldehyde / silicon dioxide composite microspheres, and 5 parts of chitosan into the flask, continue to blow nitrogen under vacuum, and quickly stir for 1 After -2 hours, the solution becomes viscous, stop vacuuming and nitrogen, continue to react ...

Embodiment 3

[0039] Embodiment 3: the improved bra steel ring provided by this embodiment and its processing method, and the bra made of the improved bra steel ring, its overall technical scheme is basically the same as that of embodiment 1-2, the difference is that this embodiment The processing method of the improved bra rim provided by example, it comprises the steps:

[0040] (1) Preparation of modified thermoplastic polyurethane elastomer material: Add 50 parts of the measured copolyether into a four-neck flask, vacuumize nitrogen, control the temperature at 100°C to remove moisture, add 35 parts of isocyanate and 5 parts of organotin, and Stir, pre-polymerize at 110°C for 1-2 hours, then add 13 parts of diol, 20 parts of urea-formaldehyde / silicon dioxide composite microspheres, and 8 parts of chitosan into the flask, continue to blow nitrogen under vacuum, and quickly stir for 1 After -2 hours, the solution becomes viscous, stop vacuuming and nitrogen, continue to react for 3-5 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com