Positioning spray demoulding device and ice cream demoulding method

A demoulding device and demoulding position technology, which can be used in frozen desserts, food science, applications, etc., and can solve the problem of different melting effects in front of ice cream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

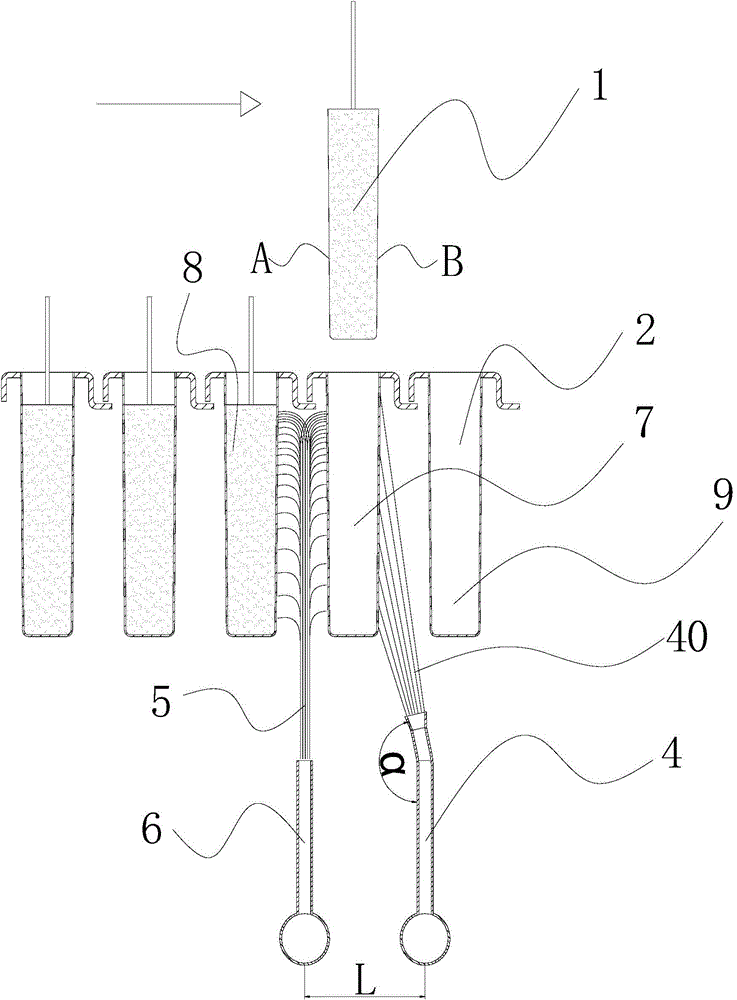

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

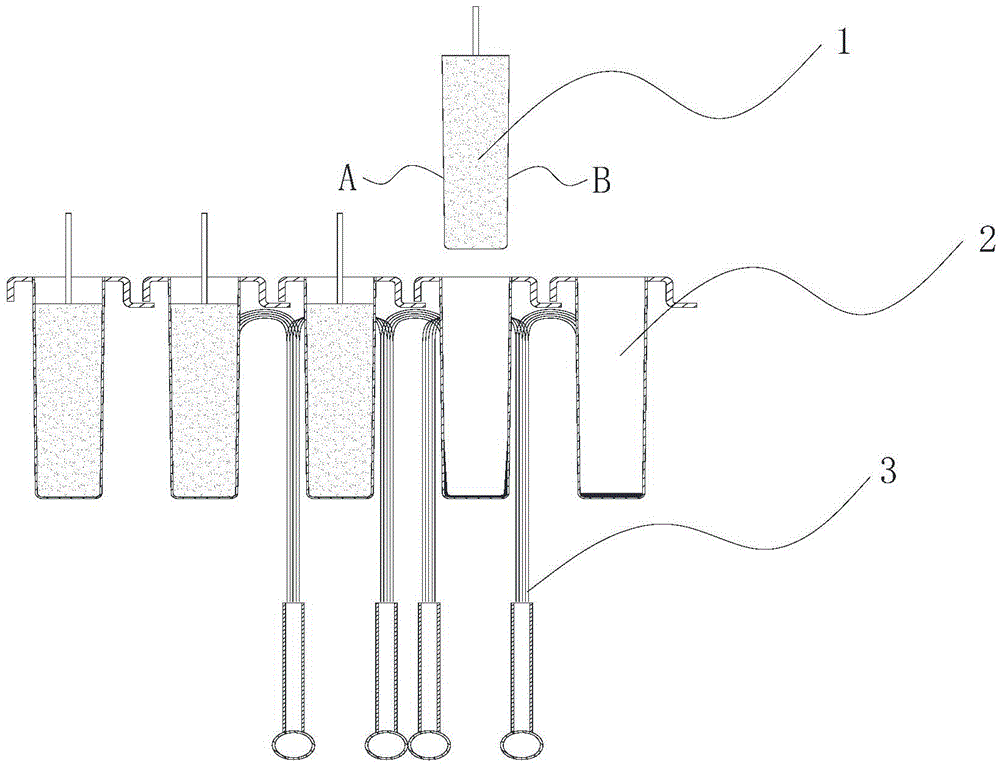

[0026] like figure 2 As shown, the present invention proposes a positioning spray demoulding device, which is used to demould the ice cream 1 on the ice cream production line from the frozen mold 2, and the positioning spray demoulding device includes:

[0027] Spray pipe 6 is arranged at the middle position between the mold at demoulding position 7 and the mold at position 8 before demoulding, and said demoulding position 7 is the position where ice cream 1 escapes from mold 2; said spray pipe The water flow direction of the outlet of 6 is vertically upward; the spray water flow 5 of the spray pipe 6 makes the mold at the demoulding position 7 and the mold at the position 8 before demoulding receive the same amount of water spray;

[0028] The atomizing shower head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com