Transmission line deicer with moving function

A transmission line and action technology, applied in the application field of transmission line protection equipment, can solve the problems of troublesome efficiency, high cost, long melting time, etc., and achieve the effects of compact structure, improved stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

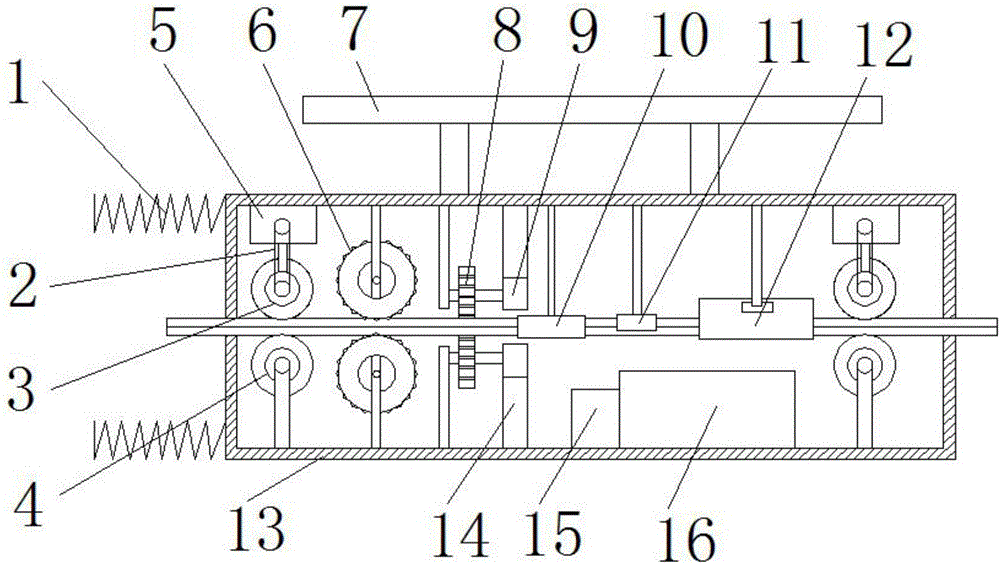

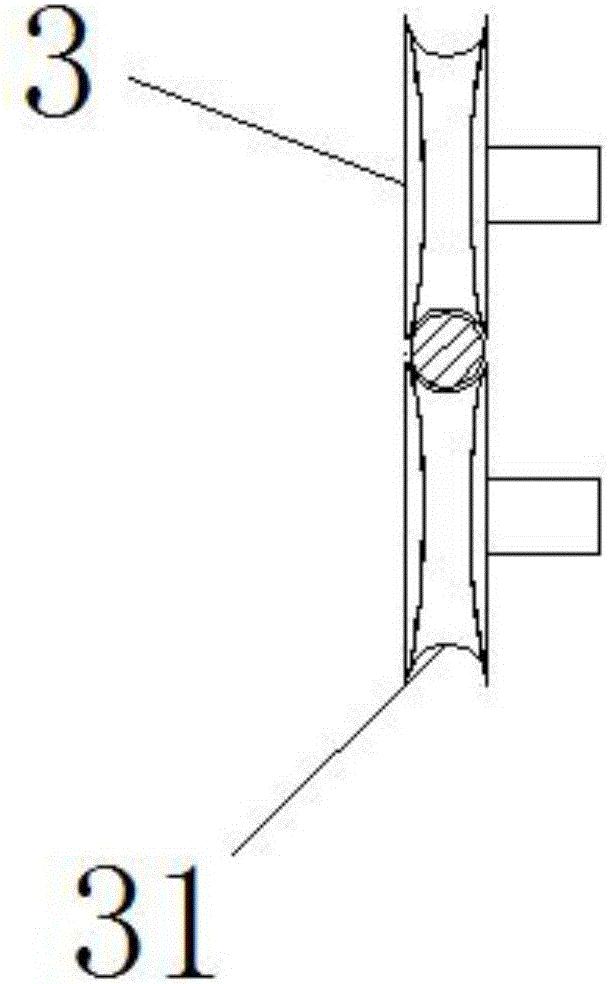

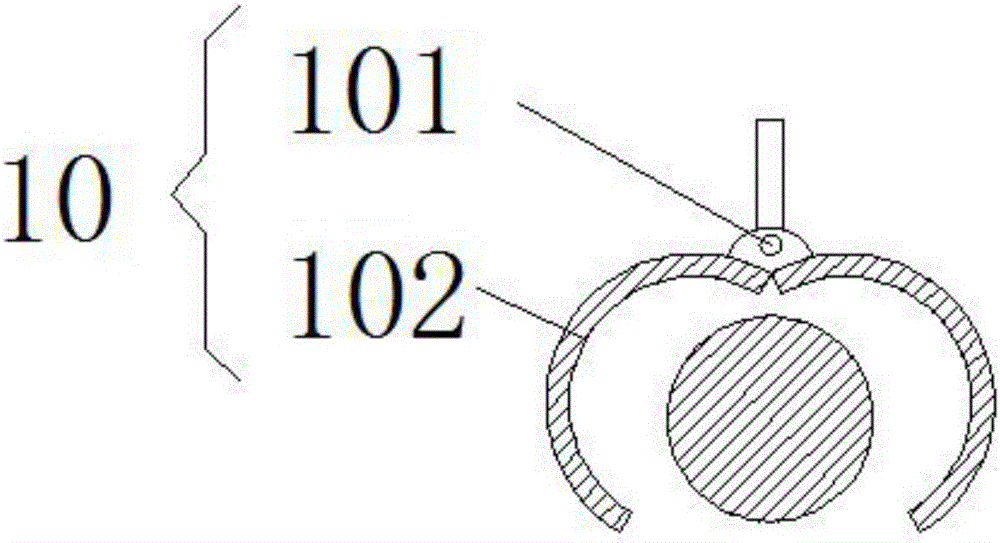

[0022] Example: such as Figure 1-5 As shown, the present invention provides a power line deicing device with action, including a body 13, an anti-collision spring 1 is arranged on one side of the body 13, a solar panel 7 is arranged on the upper side of the body 13, and the A first motor 5 is arranged on one side of the lower end surface of the inner cavity of the body 13, and the first motor 5 is connected to the driving wheel 3 through a belt 2. The lower side of the driving wheel 3 is provided with a driven wheel 4, and the driving wheel 3 One side of the longitudinal deicing wheel 6 is provided with a horizontal deicing wheel 8 on one side of the longitudinal deicing wheel 6, and the horizontal deicing wheel 8 is connected to the rotating shaft of the second motor 9 through transmission. The second motor 9 One side of the electric heater 10 is provided with an electric heater 10, and the electric heater 10 is installed in contact with the power line, and one side of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com