Pre-drying apparatus, film layer preparing method, luminescent device and preparation method thereof

A light-emitting device and pre-drying technology, applied in the optical field, can solve the problems of uneven film morphology and different solvent volatilization rates, and achieve the effect of avoiding uneven morphology and improving luminous quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

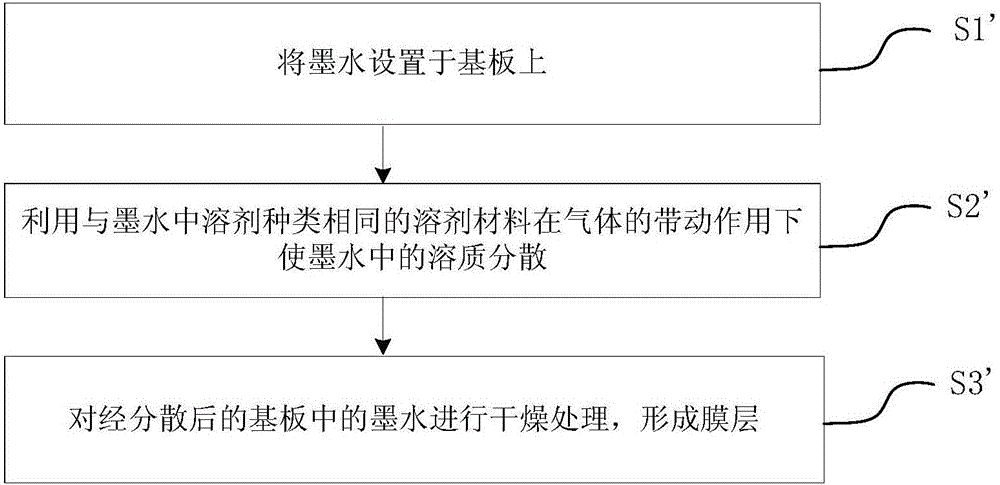

[0044] According to another aspect of the present invention, a kind of preparation method of film layer is provided, such as image 3 As shown, it includes the following steps: step S1', setting the ink on the substrate; step S2', using the same solvent material as the solvent in the ink to disperse the solute in the ink under the action of the gas; step S3', for The dispersed ink in the substrate is dried to form a film layer.

[0045] In the preparation method of the film layer of the present invention, since the ink is arranged on the substrate, and the solvent material is evenly dispersed by the gas, the ink on the substrate can be in a uniform solvent atmosphere, and the area located in the middle of the substrate is uniform. It flows and spreads, thereby effectively avoiding the problem of uneven morphology of the film after drying caused by the different solvent volatilization rates of inks on the surface of the substrate, and improving the performance of the device wit...

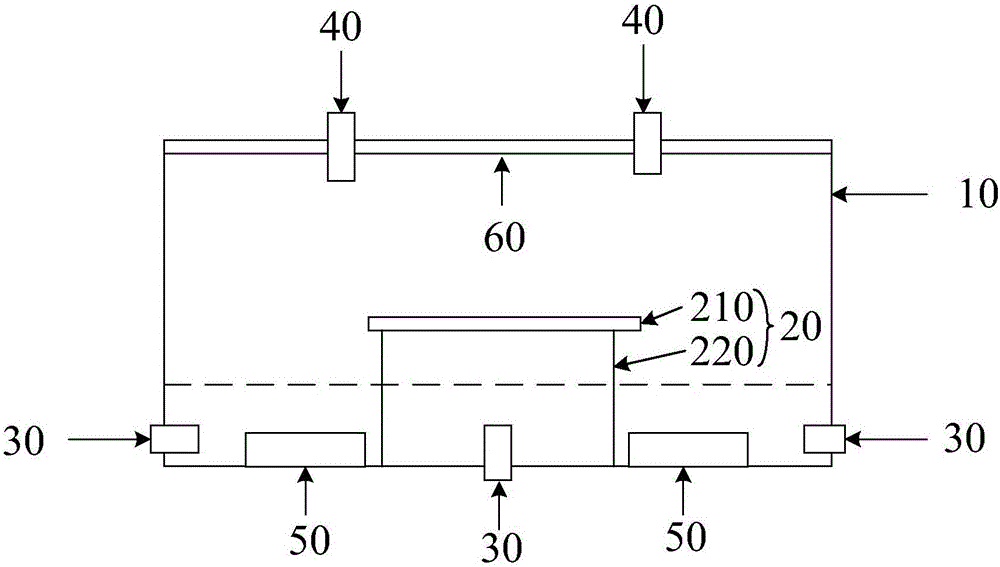

Embodiment 1

[0065] The pre-drying device provided in this embodiment includes a box body and a stage arranged in the box body, the box body is provided with a box door, an air inlet and an air outlet, and the vertical distance between the air inlet and the bottom surface of the box body is less than The vertical distance between the upper surface of the loading platform and the bottom surface of the box body, and the vertical distance between the air outlet and the bottom surface of the box body are greater than the vertical distance between the upper surface of the loading platform and the bottom surface of the box body.

[0066] Wherein, there is one air outlet, which is arranged on the top surface of the box body, and is located at the center of the upper surface of the loading platform.

[0067] There is one air inlet, which is arranged on a side wall of the box body.

Embodiment 2

[0069] The difference between the pre-drying device provided in this embodiment and embodiment 1 is:

[0070] There are two air outlets, which are arranged on the top surface of the box body, and are respectively located on both sides of the center position on the upper surface of the stage. The minimum vertical distances between the air outlets arranged on the top surface and the center position are equal.

[0071] There is one air inlet, which is arranged on the bottom surface of the box body, and the projection of the center of the upper surface of the object stage on the bottom surface is located in the air inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com