Power package with integrated magnetic field sensor

A magnetic field sensor and packaging technology, which is applied in the fields of magnetic field controlled resistors, parts of electromagnetic equipment, devices applying electro-magnetic effects, etc., which can solve the problems of needing calibration work and increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

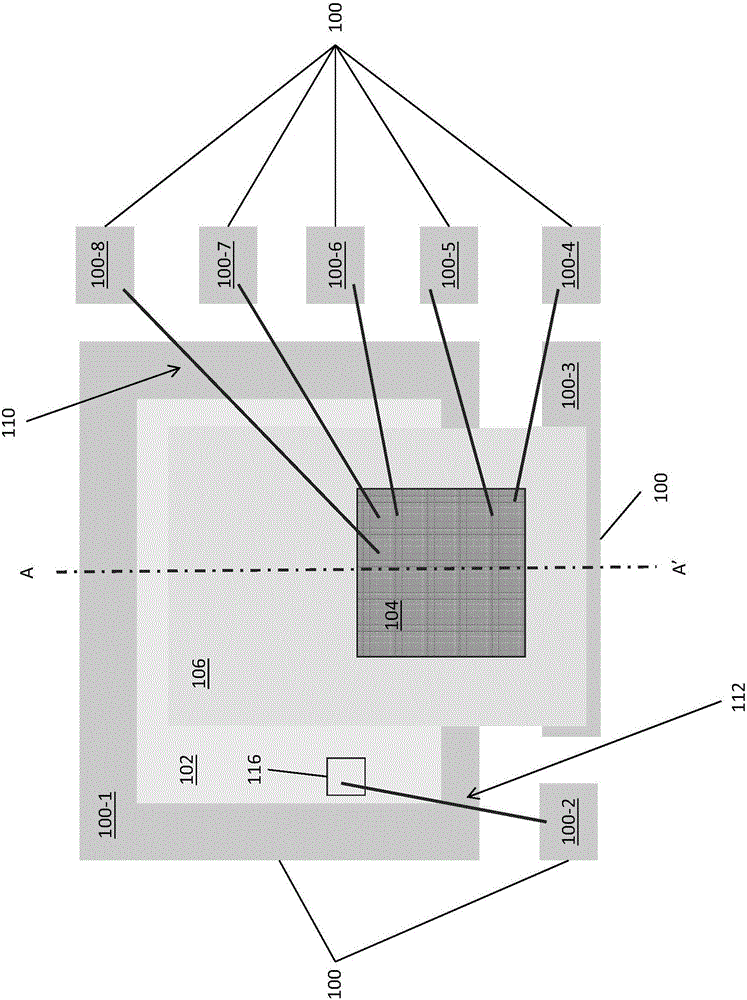

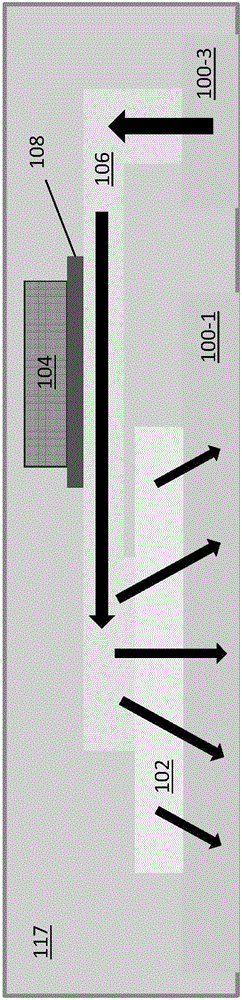

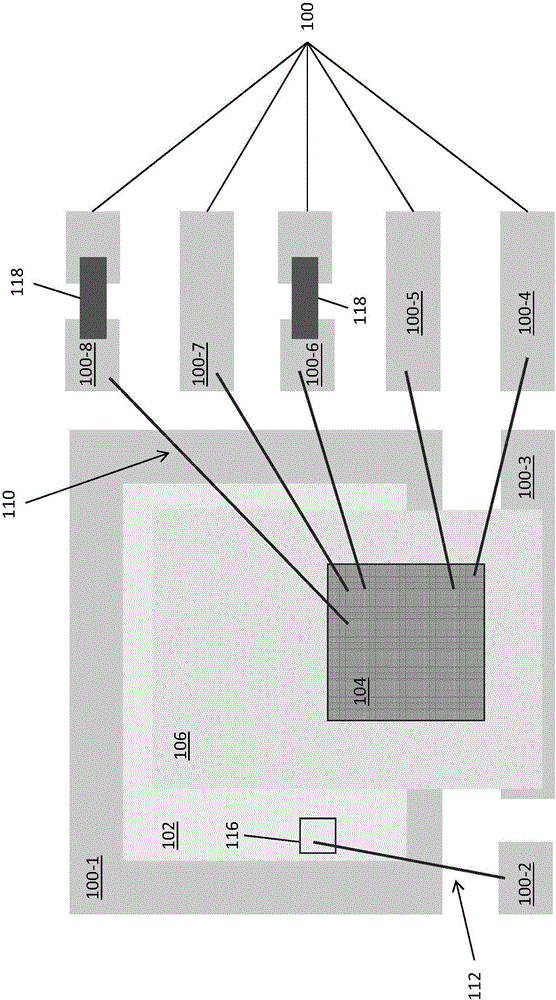

[0023] Embodiments described herein provide for integrating a magnetic field sensor, such as a magnetoresistive (XMR) sensor or a Hall sensor, into a power semiconductor package for integrated current and / or temperature measurement. The magnetic field sensor generates a signal in response to a magnetic field generated by a current flowing in a current path of a power semiconductor die included in the package. The magnitude of the signal is proportional to the amount of current flowing in the current path and is indicative of the current consumption of the power semiconductor die and / or the temperature of the package. The power semiconductor package may or may not be provided with galvanic isolation between the magnetic field sensor and the power semiconductor die. In each case, the magnetic field sensor may be integrated into the same power semiconductor package as the power semiconductor die for which current and / or temperature measurements are desired. For example, a magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com