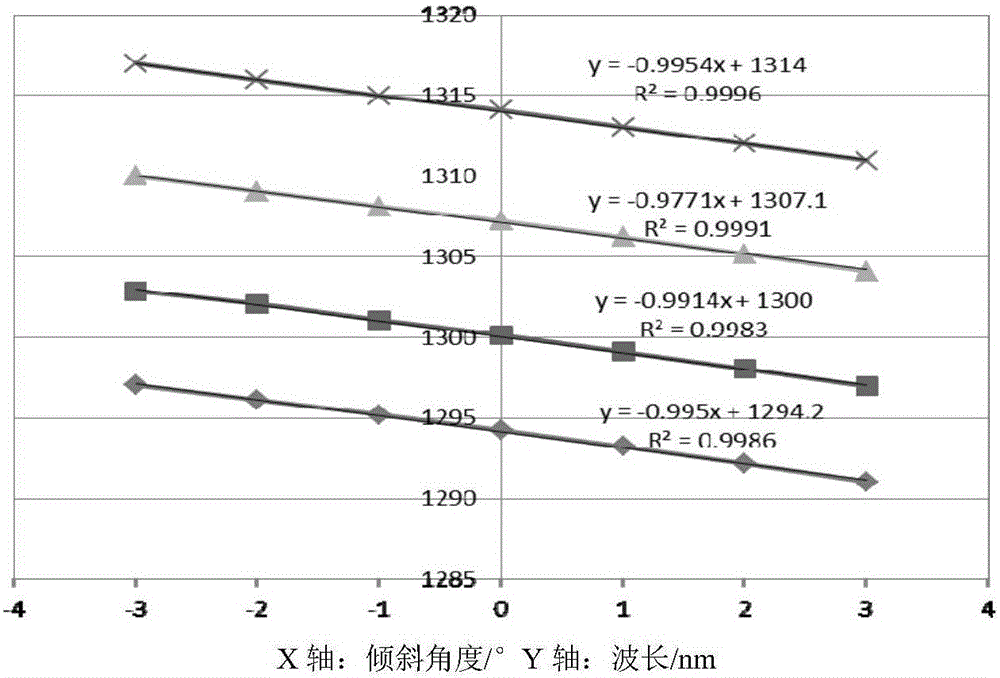

Optical fiber tilt angle sensor and wavelength division multiplexing method thereof

An inclination sensor and wavelength division multiplexing technology, applied in the direction of instruments, measuring inclination, measuring devices, etc., can solve the problems that the measurement accuracy is difficult to meet the measurement requirements, and achieve the goals of reducing measurement costs, simple sensing principle, and avoiding deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples and drawings.

[0021] The present invention provides an optical fiber inclination sensor, such as figure 1 As shown, it includes a housing 2, a rotating shaft 3, a swing arm 4, and a pendulum 5, wherein the rotating shaft 3 is arranged in the upper part of the housing 2, and the pendulum 5 is connected to the rotating shaft 3 through the swing arm 4 to form a structure that can only swing in a single plane For a single pendulum system, the swing arm 4 is provided with a central hole, and a filter 6 is provided on the central hole. The two sides of the filter 6 are respectively provided with a light input end 8 and an output end 10, and the filter 6 A collimator 9 is provided between the input end and between the filter 6 and the output end, and the filter 6 is coaxial with the collimator 9.

[0022] Further, it also includes a mounting base 1 on which the housing 2 is fixed.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com