Equipment for low-nitrogen combustion and method for low-nitrogen combustion

A low-nitrogen combustion and ignition device technology, applied in the direction of combustion methods, burners, combustion types, etc., can solve the problems of not fundamentally inhibiting the synthesis of nitrogen oxides, the large area of natural gas dilution pipelines, and the small flow of combustion-supporting air, etc., to achieve The structure is simple, the overall structure is compact and reasonable, and the effect of reducing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

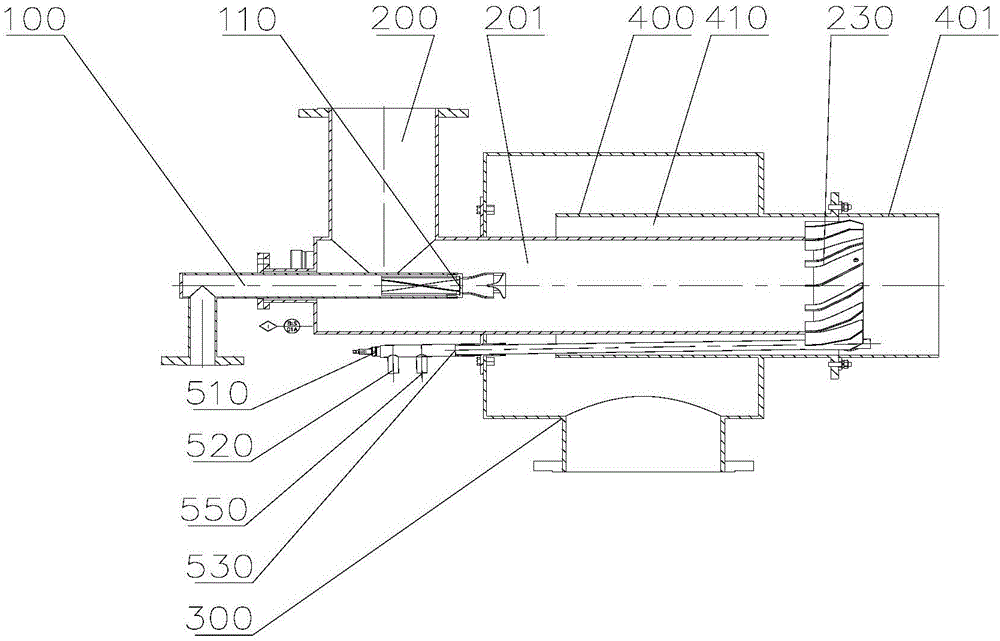

[0056] Figure 4 It is a structural schematic diagram showing the first embodiment of the natural gas nozzle in the low-nitrogen combustion device of the present invention. Figure 5 It is a left view showing the structural schematic diagram of the first embodiment of the natural gas nozzle in the low-nitrogen combustion device of the present invention.

[0057] Such as Figure 4 and Figure 5 As shown, the natural gas nozzle 110 is formed by the front end of the natural gas pipe 100 , and the natural gas nozzle 110 is provided with a twist plate 111 at the center of the outlet end of the natural gas pipe 100 . After the natural gas is ejected through the twist plate 111, it enters the natural gas dilution pipe 201 in a swirl shape, pushing the flue gas in the natural gas dilution pipe 201 forward, and mixing with the flue gas at the outlet end of the natural gas dilution pipe 201 .

no. 2 example

[0059] Figure 6 It is a structural schematic diagram showing the second embodiment of the natural gas nozzle in the low-nitrogen combustion device of the present invention.

[0060] Such as Figure 6 As shown, the natural gas spray head 110 is formed by the front end of the natural gas pipe 100 , and a flow guide pipe 112 and a flow guide cover 113 are installed at the outlet end of the natural gas spray head 110 .

[0061] Specifically, a twist plate 111 is arranged in the natural gas spray head 110 and is located at the center of the outlet end of the natural gas pipe 100 . On this basis, a flow guide pipe 112 and a conical flow guide cover 113 are added at the outlet end of the natural gas spray head 110 . After the natural gas passes through the twist plate 111, it is in a vortex shape, and the vortex-shaped natural gas enters the arc-shaped shroud 113 through the outlet of the guide tube 112, so that the natural gas diffuses into the natural gas dilution pipe 201 along...

no. 3 example

[0063] Figure 7 It is a structural schematic diagram showing the third embodiment of the natural gas nozzle in the low-nitrogen combustion device of the present invention. Figure 8 It is a cross-sectional view of A-A showing the structure diagram of the third embodiment of the natural gas nozzle in the low-nitrogen combustion device of the present invention. .

[0064] Such as Figure 7 and Figure 8 As shown, the natural gas nozzle 110 is formed by the front end of the natural gas pipe 100 , and a plurality of circular through holes with the same radius are formed on the pipe wall of the natural gas nozzle 110 . The natural gas enters the natural gas dilution pipe 201 through the through hole on the natural gas nozzle 110 , pushes the flue gas in the natural gas dilution pipe 201 forward, and mixes with the flue gas at the outlet end of the natural gas dilution pipe 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com