A method for adjusting the secondary air of a w-flame once-through boiler

An adjustment method and technology of once-through boilers, which are applied in the combustion method, adjustment of air supply, control of combustion, etc., can solve the problems of insufficient combustion of pulverized coal, incomplete combustion of solids, and reduced unit economy, and achieve good actual inspection results. The effect of improving pulverized coal combustion efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

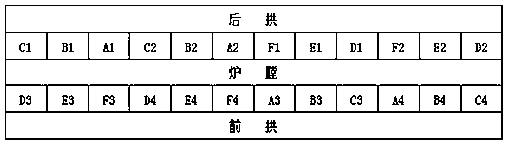

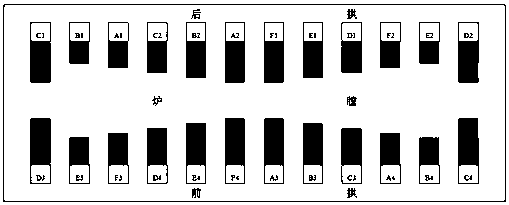

[0013] Example: such as figure 1 As shown, burners are installed on the front and rear arches of the furnace 1, the burners include a row of front and rear arches, each row is provided with twelve burners, and the front row of burners are D3, E3, F3, D4, E4, F4, A3, B3, C3, A4, B4, C4, rear burners from left to right are C1, B1, A1, C2, B2, A2, F1, E1, D1, F2, E2, D4, The two rows of burners are placed correspondingly from left to right.

[0014] The boiler furnace width direction is adjusted according to the following adjustment methods for the secondary air distribution:

[0015] a. Increase the secondary air of the burners in the areas on both sides of the furnace, and the number of burners in the areas on both sides of the furnace is four, namely C1, C4, D2, and D3;

[0016] b. The secondary air opening of the front arch of the furnace is 5%~10% larger than that of the rear arch;

[0017] c. The opening of the secondary air is arranged in a triangle, the central area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com