Improved structure of air bearing

A technology of air bearing and structure, which is applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of heat loss, bearing deformation, high cost, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] That is to say, a preferred embodiment of the present invention will be given together with the drawings for further description.

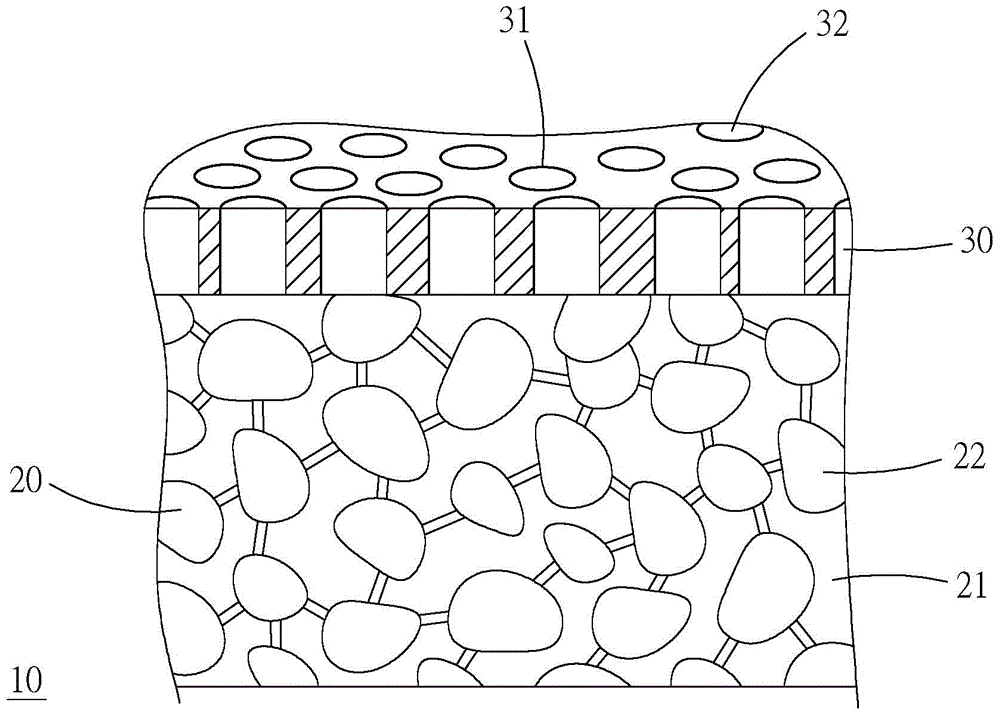

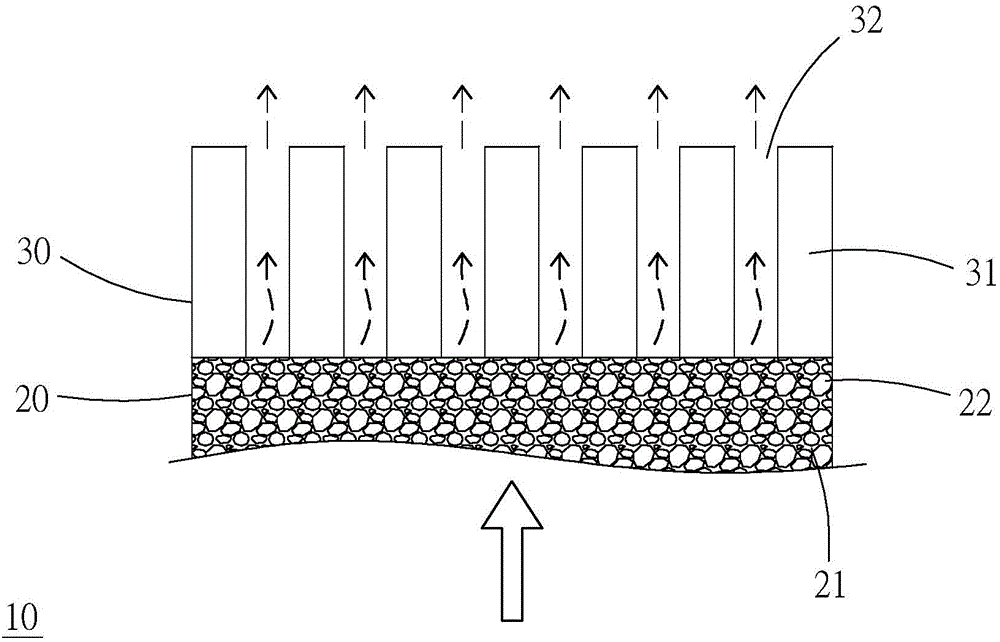

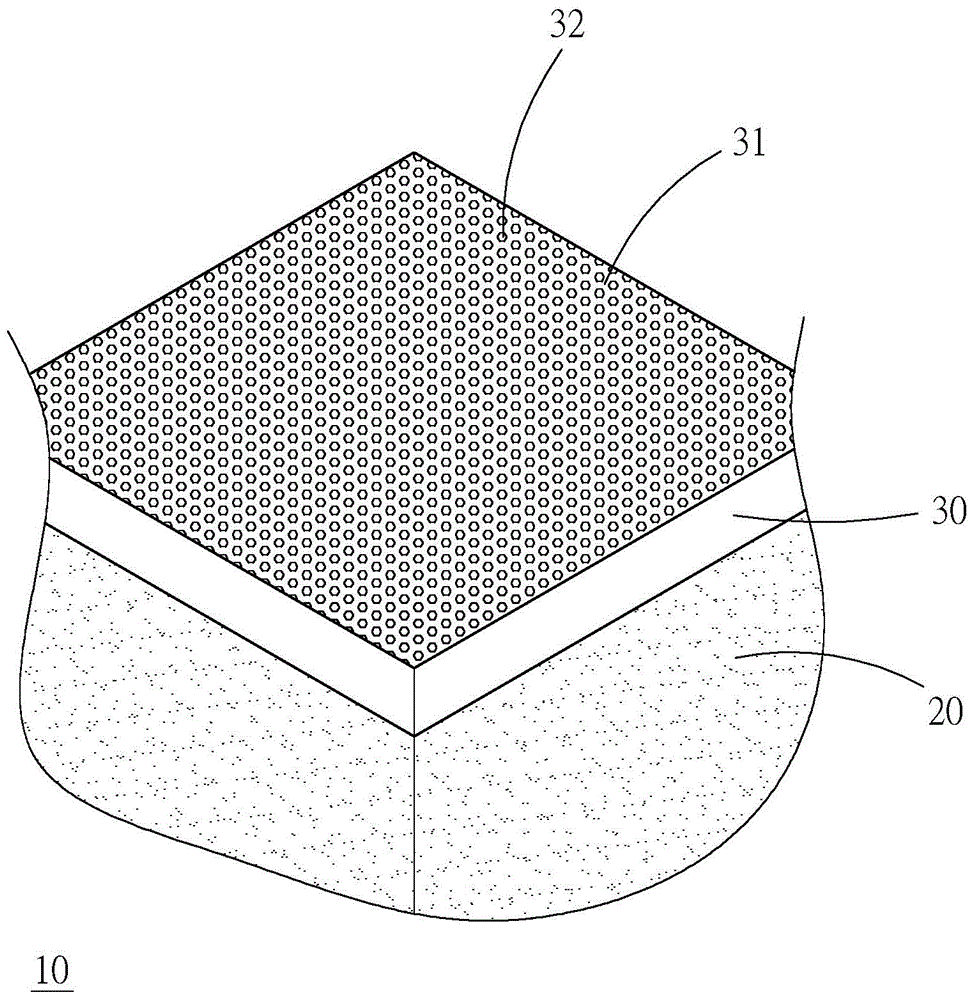

[0023] see Figure 1 to Figure 4 As shown, the air bearing improved structure 10 provided in the first preferred embodiment of the present invention mainly includes a porous body 20 and a throttle layer portion 30, wherein:

[0024] The porous body 20 is made by a known sintering technique, and has a base 21, an air chamber 22 located inside the base 21 and formed by a plurality of voids communicating with each other, and the plurality of voids constitute a gas flow path , so as to obtain the effect similar to that of the known porous restrictor.

[0025] The throttling layer portion 30 is composed of an aluminum layer 31 and a plurality of through holes 32 with a predetermined length, and is arranged on one end surface of the porous body 20. Further, the aluminum layer 31 is deposited by physical vapor deposition ( Physical Vapor Deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com