Preparation device and method of sample used for measuring volume change of asphalt mixture by induction heating

An asphalt mixture and induction heating technology, which is applied in the preparation of test samples, material gluing, mechanical equipment, etc., can solve the problems of difficulty in attaching two patches to a symmetrical fixed position, error in test results, etc. Small footprint, easy installation and use, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

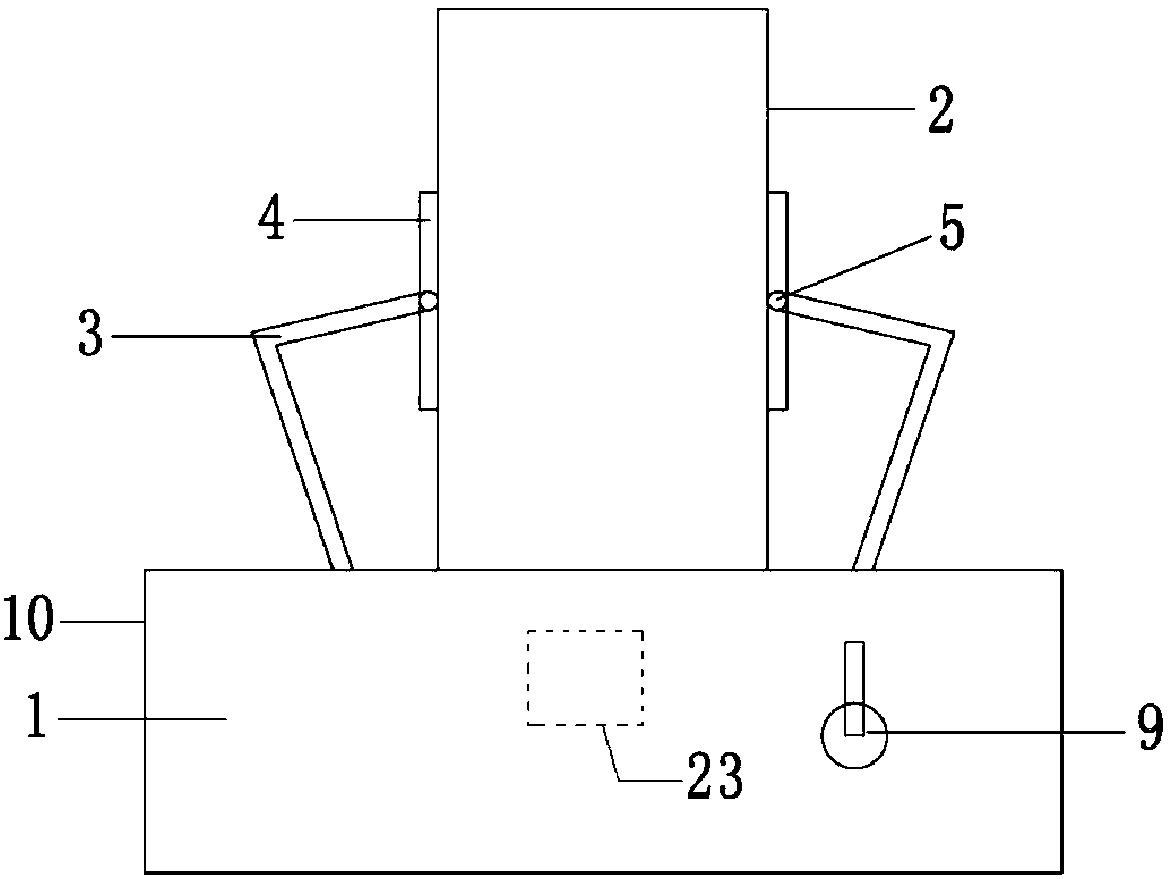

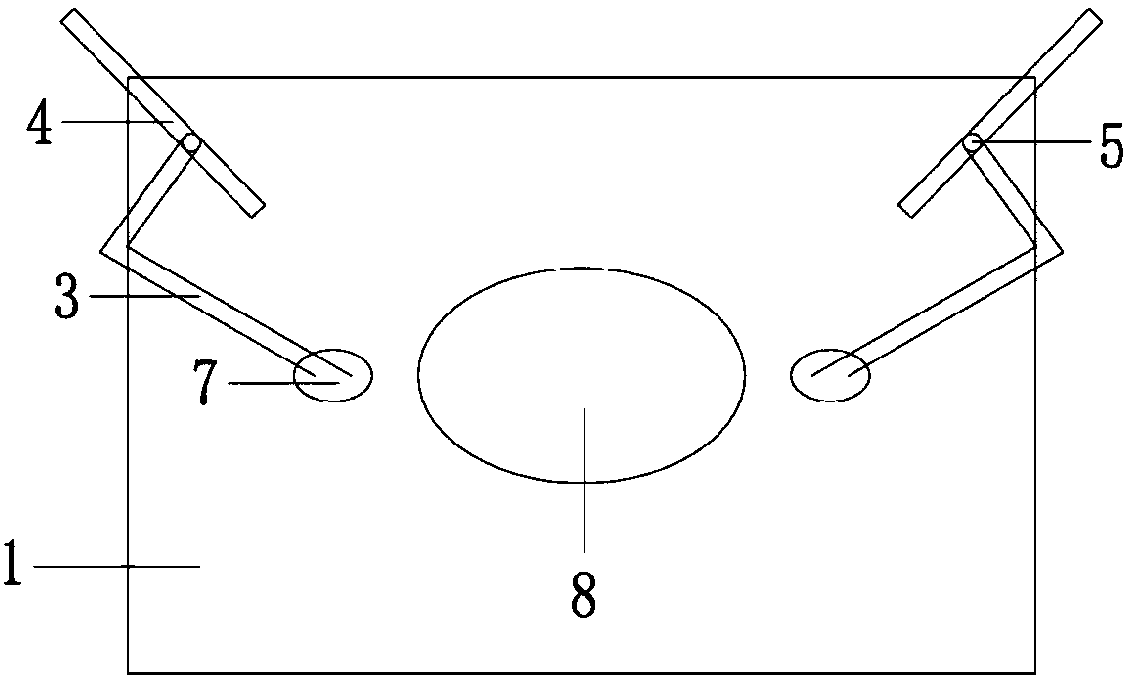

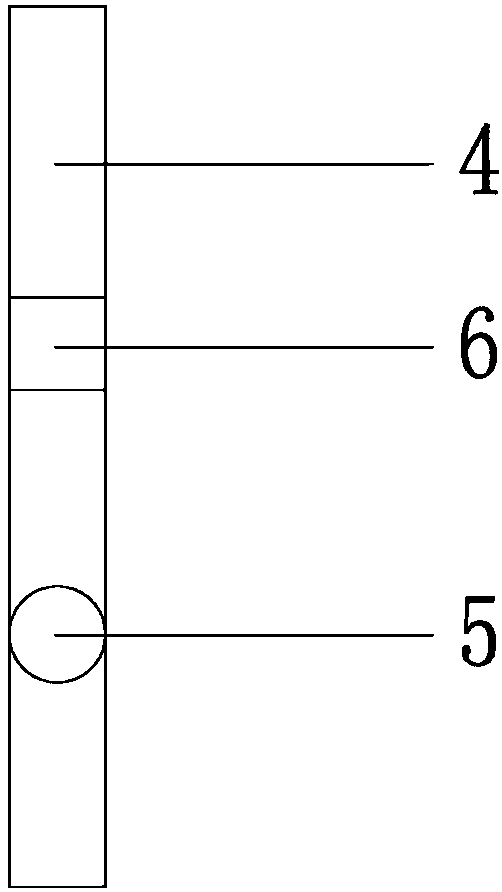

[0016] A device for preparing samples used when measuring the volume change of asphalt mixture by induction heating, comprising a control box 1, a Marshall test piece support platform 8 is arranged above the plane of the control box 1; the control box 1 includes a box body 10, an electronic Circuit board and hydraulic pump, and the control button 9 on the outer wall of the casing; Controller 23 is installed on the electronic circuit board; Displacement controller 7, control button 9 and hydraulic pump all join with controller 23; Displacement controller 7 It is elliptical, and there are two symmetrically arranged on both sides of the Marshall test piece bearing platform 8; the position fixing rod 3 is in the shape of "7", and its lower end passes through the displacement controller 7 to connect with the hydraulic pump, and the other upper end passes through the movable rod The rotating interface 5 on the 4 is connected to the movable rod 4; the movable rod 4 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com