Structure improved magnetic pump

A technology of structural improvement and magnetic pump, which is applied to pumps, parts of pumping devices for elastic fluids, pump devices, etc., can solve problems such as uneven material, medium leakage, and deteriorating working environment, and achieve enhanced anti-dry wear performance, improved corrosion resistance, and improved operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

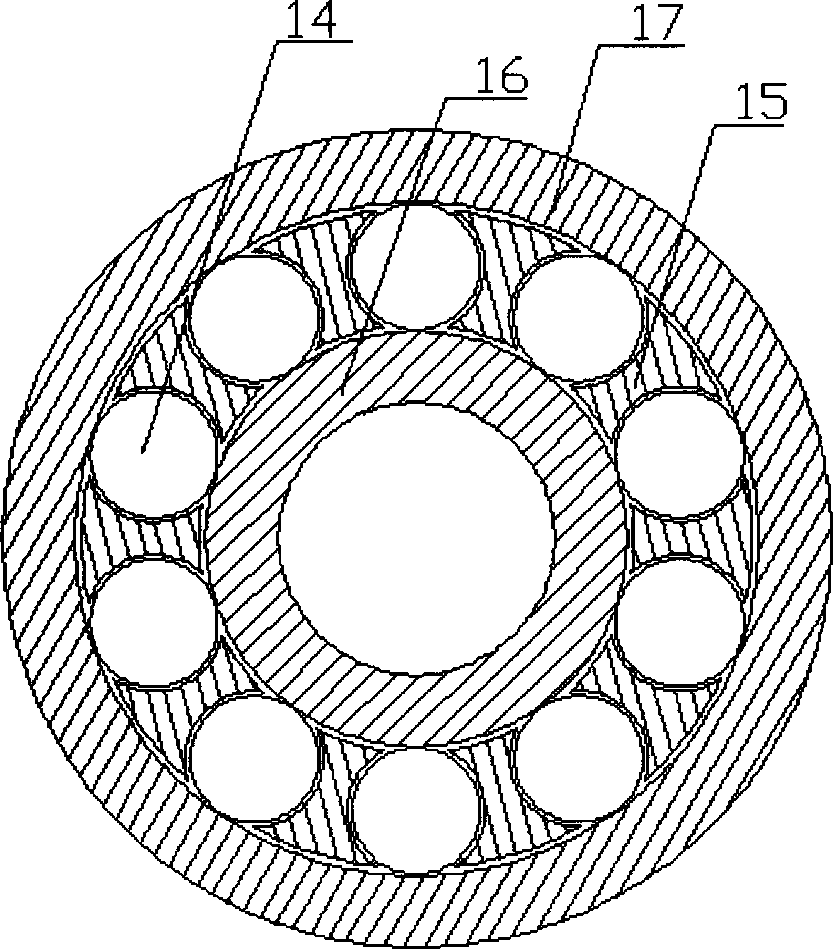

[0012] Embodiment 1: A magnetic pump with improved structure, including a pump body 1, a pump cover 3, a pump shaft 7, an impeller 2, an inner magnetic rotor 5, an outer magnetic rotor 6 and a spacer sleeve 4, and the inner magnetic rotor 5 is fixedly mounted on the pump The shaft end of the shaft 7, the outer magnetic rotor 6 is installed on the shaft end of the motor, the spacer sleeve 4 is set between the inner magnetic rotor 5 and the outer magnetic rotor 6, the spacer sleeve 4 and the pump cover 3 are sealed and fixedly connected, the pump body 1 and the pump cover 3 are tightly connected, the pump body 1, the pump cover 3, and the isolation sleeve 4 are closed to form a pump chamber. When the magnetic pump is working, the outer magnetic rotor 6 is driven by the external driving force to rotate, and the gap between the outer magnetic rotor 6 and the inner magnetic rotor 5 The inner magnetic rotor 5 is driven to rotate by magnetic force, and the inner magnetic rotor 5 drive...

Embodiment 2

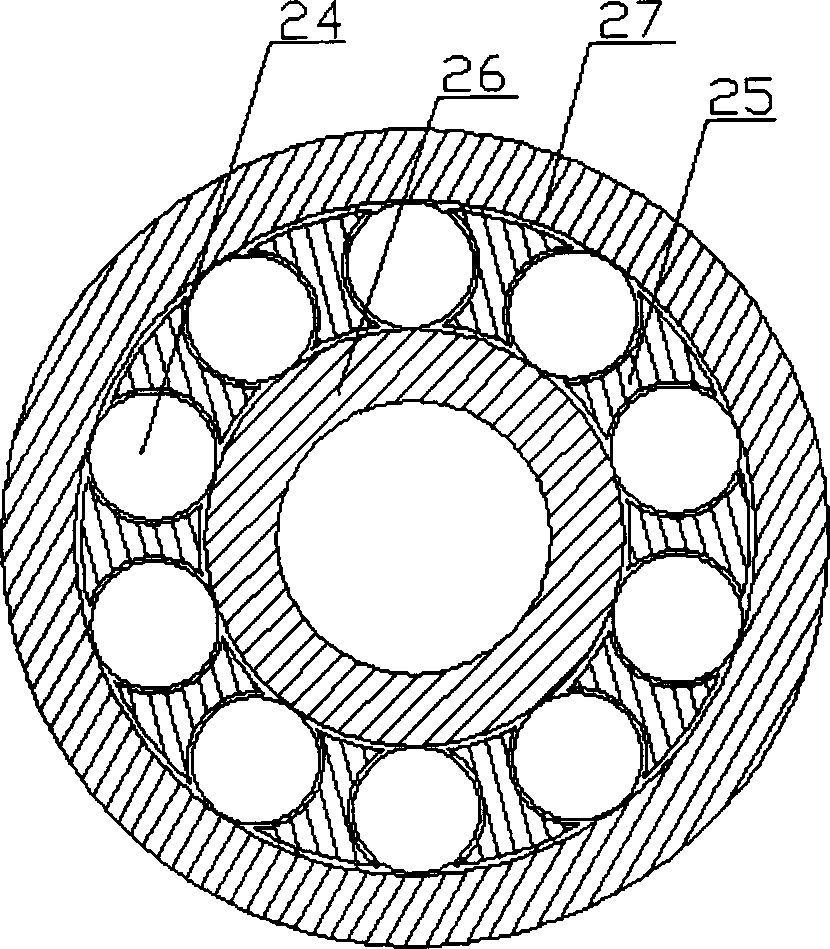

[0017] Embodiment 2: A magnetic pump with improved structure, including a pump body 1, a pump cover 3, a pump shaft 7, an impeller 2, an inner magnetic rotor 5, an outer magnetic rotor 6 and a spacer sleeve 4, and the inner magnetic rotor 5 is fixedly mounted on the pump The shaft end of the shaft 7, the outer magnetic rotor 6 is installed on the shaft end of the motor, the spacer sleeve 4 is set between the inner magnetic rotor 5 and the outer magnetic rotor 6, the spacer sleeve 4 and the pump cover 3 are sealed and fixedly connected, the pump body 1 and the pump cover 3 are tightly connected, the pump body 1, the pump cover 3, and the isolation sleeve 4 are closed to form a pump chamber. When the magnetic pump is working, the outer magnetic rotor 6 is driven by the external driving force to rotate, and the gap between the outer magnetic rotor 6 and the inner magnetic rotor 5 The inner magnetic rotor 5 is driven to rotate by magnetic force, and the inner magnetic rotor 5 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com