Assembling machine of high altitude prefabricated slabs

A panel installation machine and prefabricated panel technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of low manpower construction efficiency, impossible construction by crane, impact on project cost, etc., and achieve easy use and control, and reliable driving , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

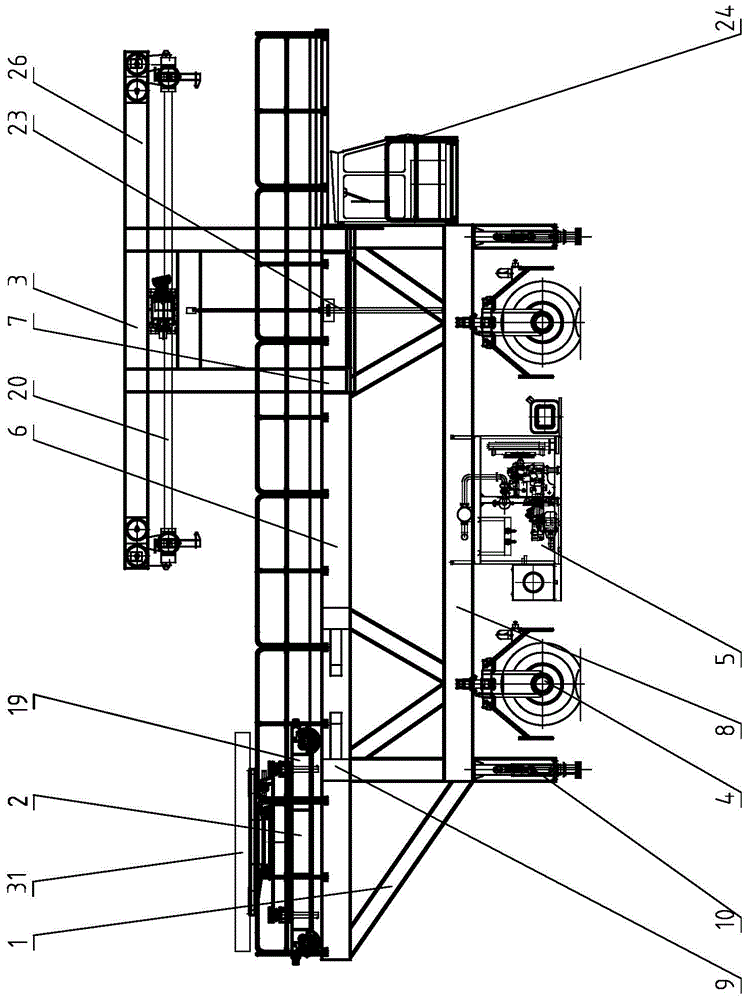

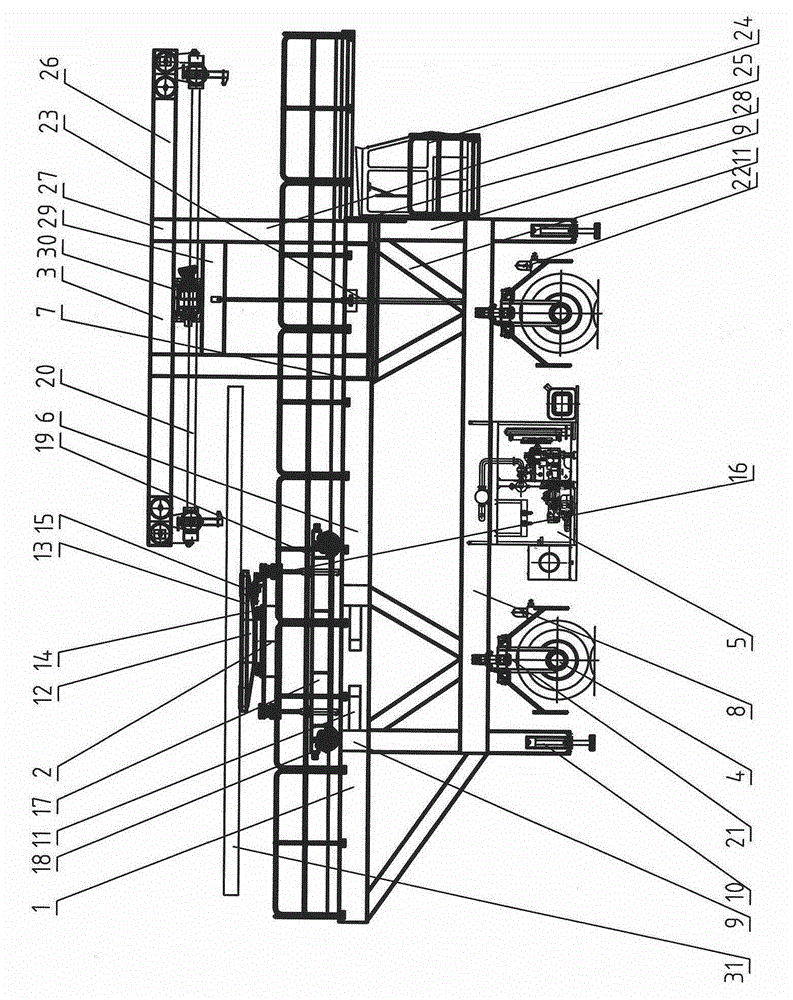

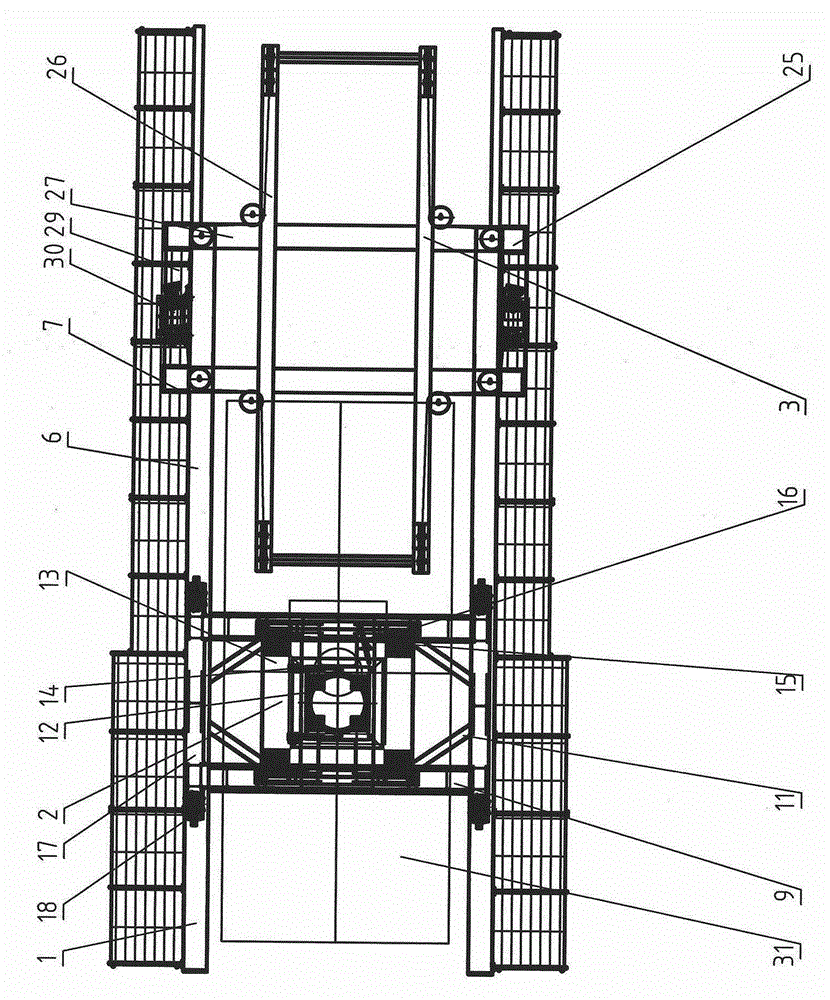

[0043] Such as figure 1As shown, the high-altitude prefabricated panel installation machine of the present invention includes: main structure 1, mobile lift car 2, crane 3, traveling wheel set 4, engine set 5, track beam 6, cab 24, is characterized in that: main structure 1 A mobile elevator 2 and a crane 3 are installed above, a traveling wheel set 4 is installed below the main structure 1, an engine unit 5 is installed in the middle of the main structure 1 and provides power for the whole machine, and a cab 24 is installed at the front of the main structure 1. The mobile lift car 2 above the main structure 1 can move back and forth along the track beam 6, the mobile lift car 2 itself can be lifted and rotated, the height of the crane 3 above the main structure 1 can be adjusted, and the crane 3 is controlled by the cab 24 The prefabricated panel 31 can be hoisted or put down, and the lifting vehicle 2 can be moved under the control of the driver's cab 24 to transport the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com