Development of kenaf and cotton blended yarns

A technology of cotton blended and blended yarns, which is applied in the textile field, can solve the problems that have not been found in the literature related to kenaf and cotton blended yarns, and achieve the effects of improving softness, shortening the processing process, and improving elasticity and curling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

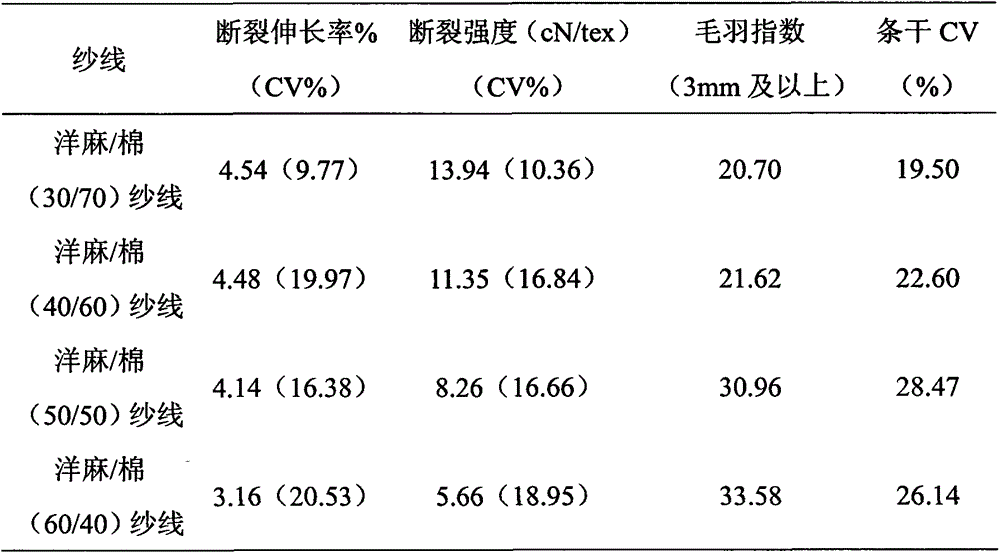

[0021] Spinning kenaf / cotton (30 / 70) blended yarn.

[0022] 1 Kenaf soft treatment

[0023] (1) Water retting. Weigh 30 g of kenaf fiber and soak in water for 12 hours.

[0024] (2) Alkaline oxygen bath treatment. Configure alkaline oxygen bath solution, bath ratio is 1:20 (alkali oxygen solution 600g), total alkali concentration is 4% (24g), first add alkali concentration 0.8% (4.8g), hydrogen peroxide concentration 1% (mass fraction 30%) 20g of hydrogen peroxide), additives anhydrous sodium sulfite, magnesium sulfate, and sodium polyphosphate are all 3% of the dry weight of the fiber (0.9g each). Weigh 0.9g each of anhydrous sodium sulfite, magnesium sulfate, and sodium polyphosphate, 4.8g sodium hydroxide, add 523.3g water, then add 20g 30% hydrogen peroxide, and then retort the semi-dried kenaf fiber Put it into the prepared alkaline oxygen bath solution, when the temperature is raised to 95℃, add the remaining sodium hydroxide (19.2g) and water (30g) solution, keep it for 2h...

Embodiment 2

[0038] Spinning kenaf / cotton (60 / 40) blended yarn.

[0039] 1 Kenaf soft treatment

[0040] (1) Water retting. Weigh 50g of kenaf fiber and soak in water for 24h.

[0041] (2) Alkaline oxygen bath treatment. Weigh a certain amount of semi-dried kenaf fiber after retting, configure alkali-oxygen bath solution, bath ratio is 1:20 (solution 1000g), total alkali concentration is 3% (30g), first add alkali concentration 0.8% (8g) The concentration of hydrogen peroxide is 2% (67g of 30% hydrogen peroxide), and the additives anhydrous sodium sulfite, magnesium sulfate, and sodium polyphosphate are all 2% of the dry fiber weight (1g each). Weigh 1g each of anhydrous sodium sulfite, magnesium sulfate, and sodium polyphosphate, 8g sodium hydroxide, 860g water, and 67g 30% hydrogen peroxide to make an alkaline oxygen bath solution, then add the semi-dried kenaf after retting. The fiber is heated to 95°C at 1°C / min in a constant temperature water bath, and then a solution of remaining sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com