A device for preparing ni-sic composite coating on the inner surface of a hollow workpiece

A technology for hollow workpieces and composite coatings, applied in coatings, electrolytic components, electrolytic coatings, etc., can solve problems such as damage to the coating surface, achieve the effects of prolonging the service life, avoiding contamination of the plating solution, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

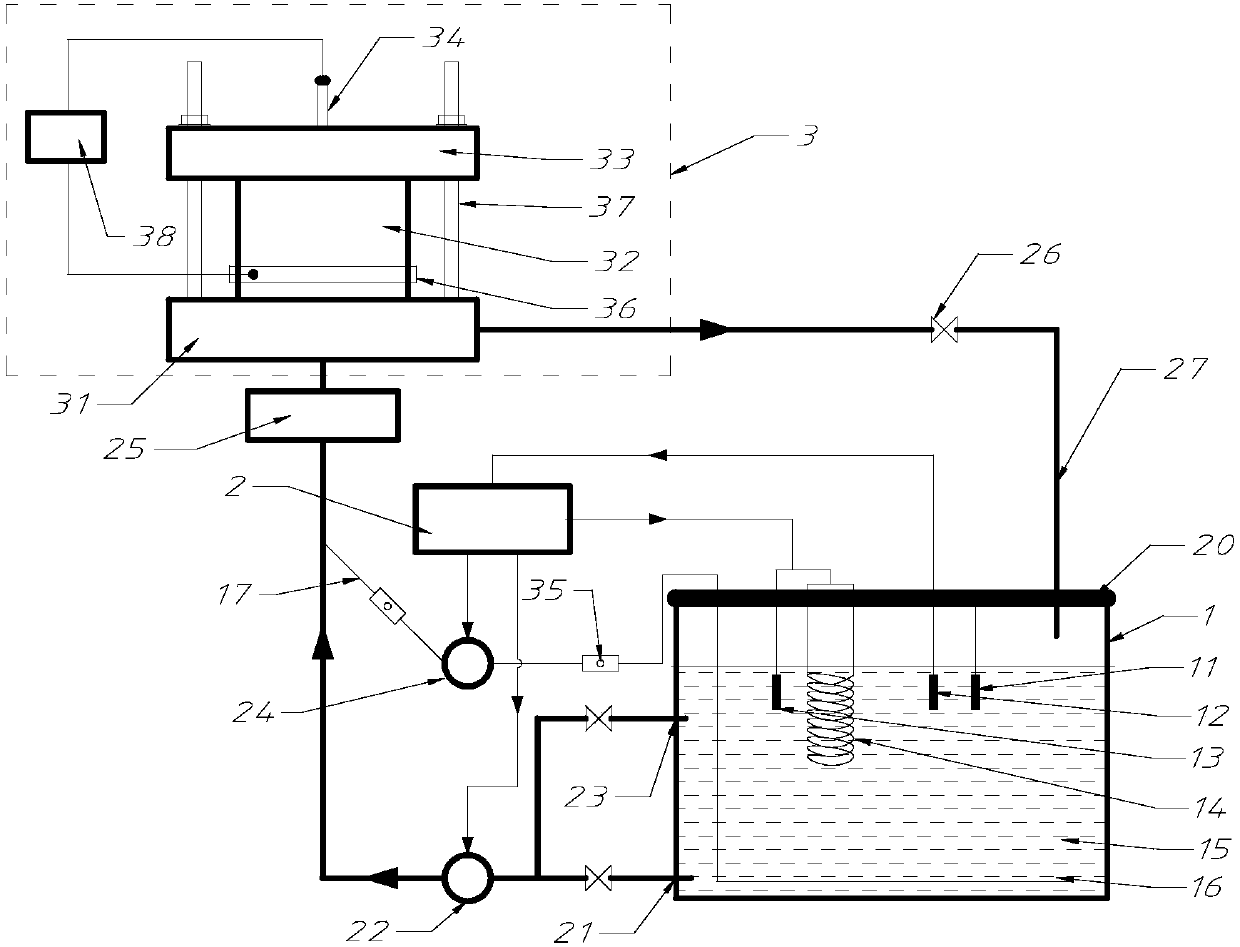

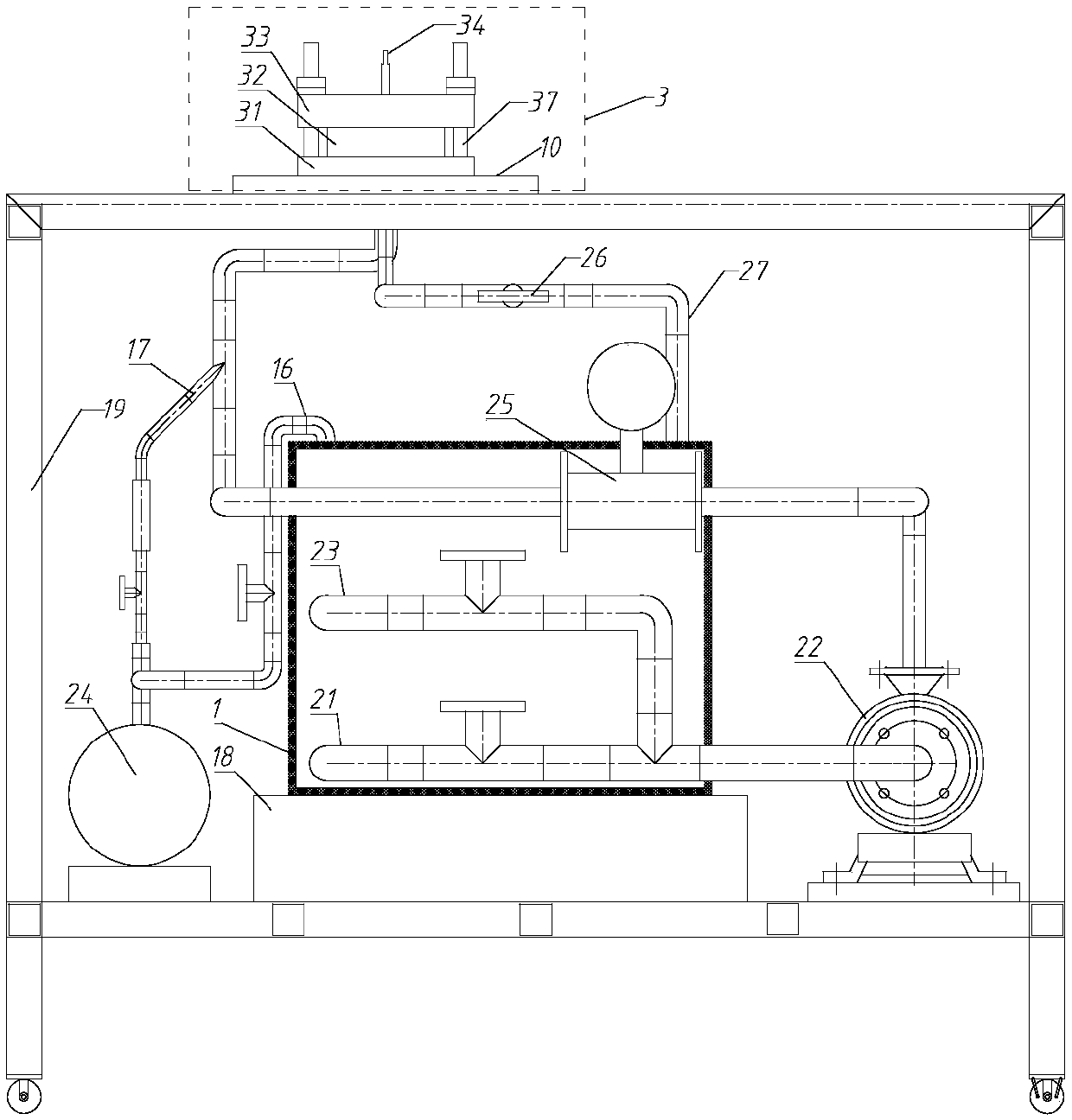

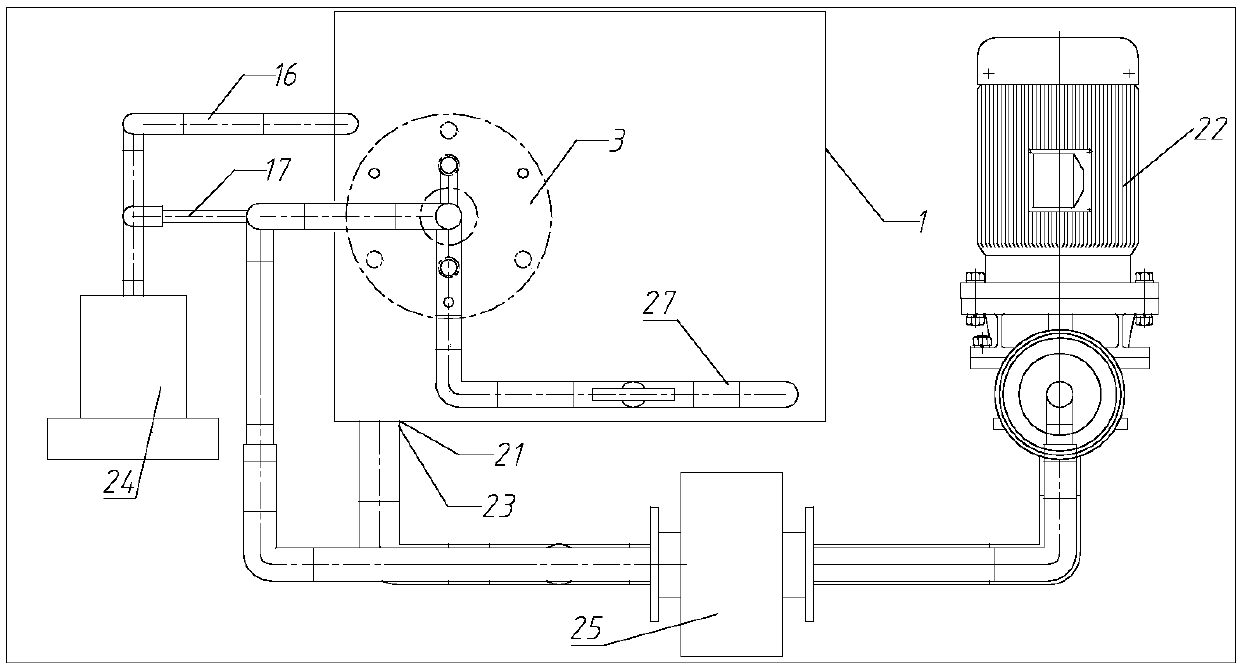

[0062] This embodiment is a device for preparing a Ni-SiC composite coating on the inner surface of a rotary workpiece, and the material of the workpiece is Q235 steel. This embodiment includes a liquid storage tank 1, a liquid storage tank tank body support 18, an electroplating solution circulation pump 22, a compressed air pump 24, an electromagnetic flowmeter 25, a sealed electroplating table 3, a nickel anode 42, a control panel 4 and an electroplating rectifier power supply 38 .

[0063] The liquid storage tank is made of PVC material with a size of 600*500*500mm, and a rectangular plate-shaped tank cover of 600*500mm made of PP material is arranged on the top of the liquid storage tank. The liquid storage tank 1 is placed on the lower panel of the tank body support 18 of the liquid storage tank. A lower water outlet pipe 21 and an upper water outlet pipe 23 are arranged in the liquid storage tank, and the entrance of the lower water outlet pipe is located at the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com